Haben Sie schon einmal ungewöhnliche Formen und Designs aus verschiedenen Metallen, Kunststoffen und Holz gesehen? Ich bin sicher, das haben Sie. Aber haben Sie sich jemals gefragt, wie diese Formen entstehen? Das ist alles den Drehmaschinen zu verdanken. Es gibt jedoch zwei Arten von Drehmaschinen: CNC-Drehmaschinen und Handdrehbänke.

Es gibt fünf Arten von CNC-Drehmaschinen. Heute wollen wir uns jedoch auf die Unterscheidung zwischen CNC-Drehmaschinen und manuellen Drehbänken konzentrieren.

Wenn Sie in das Fräsgeschäft einsteigen wollen, ist es wichtig, zwischen den beiden Arten zu unterscheiden.

Überblick über CNC-Drehmaschinen und manuelle Drehmaschinen

Wie Sie wissen, breitet sich das Fräsgeschäft weltweit aus. Die Hersteller verlassen sich auf eine Reihe von CNC-Maschinen, um dieses Verfahren auszuführen. Von diesen Maschinen werden am häufigsten CNC-Drehmaschinen und manuelle Drehmaschinen verwendet. Beide erfüllen die Aufgabe, verschiedene Materialien zu formen und zu gestalten. Was sie unterscheidet, ist die Vielseitigkeit ihrer Funktionen.

Zum Beispiel ist die CNC-Drehmaschine fortschrittlicher und präziser. Lassen Sie mich das im Detail erklären. CNC-Maschinen sind computergesteuerte Maschinen. Sie verwenden spezielle Computeranweisungen für ihren Betrieb. WIE? Eigentlich werden dem Computer verschiedene gewünschte Designs in Form von programmierten Anweisungen gegeben.

Der Computer entschlüsselt die Anweisungen und führt die CNC-Werkzeuge zur Arbeit. Daher zeichnen sich CNC-Maschinen durch ihre Präzision und Genauigkeit aus. Auf der anderen Seite arbeiten manuelle Drehmaschinen mit konventionellen Methoden. Sie verwenden menschliche Anweisungen, um Fräsvorgänge auszuführen, was ihre Präzision beeinträchtigt.

Entscheidende Unterschiede zwischen CNC-Drehmaschinen und manuellen Drehmaschinen

Haben Sie eine grundlegende Vorstellung von der Funktionsweise der beiden Maschinen bekommen? Wenn ja, sollten wir zum nächsten Schritt übergehen, nämlich dem Verständnis ihrer grundlegenden Unterschiede. Wie ich bereits sagte, unterscheiden sich beide in vielerlei Hinsicht, von der Konstruktion bis zum Betrieb. Tauchen wir ein in die Erkenntnisse und entdecken wir, was sie voneinander unterscheidet.

1-Strukturen und Entwürfe

Der Hauptunterschied liegt in ihrem Aufbau und ihrer Konstruktion. Eine manuelle Drehmaschine besteht aus vier wesentlichen Teilen: einem Bett, einem Spindelstock, einem Reitstock und einem Schlitten. Auf dem Bett wird das Werkstück platziert, und der Spindelstock hält und bewegt es. Der Reitstock hält die Fräswerkzeuge, und der Schlitten bewegt sie.

Aber denken Sie daran, dass alle diese Werkzeuge von Menschen bedient werden. Sie benutzen technische Pedale oder Räder, um die Schneidwerkzeuge zu bewegen. Mit einfachen Worten: Eine manuelle Drehmaschine ist seit vielen Jahrzehnten einfach und konventionell aufgebaut. Die CNC-Drehmaschine hat eine komplexe Geometrie und Struktur auf der gegenüberliegenden Seite.

Sie hat die gleiche Kombination aus diesen vier Teilen: Spindelstock, Reitstock, Schlitten. Wenn ja, worin besteht der Unterschied? Eigentlich steuert der Computer alle Teile. Die Halte- und Bewegungswerkzeuge folgen den Anweisungen des Computers und fertigen präzise Entwürfe an.

2- Verarbeitungsmethoden

Ich habe ihre Bestandteile im obigen Abschnitt erläutert. So wird es für Sie jetzt sehr einfach sein, ihre Verarbeitung zu verstehen. Die Arbeitsweise einer manuellen Drehmaschine ist sehr einfach. Zum Beispiel wird ein Werkstück auf das Bett gelegt, und der Spindelstock wird so eingestellt, dass er es hält und bewegt. Die Schneidewerkzeuge sind an einem Schlitten befestigt, der sich bewegt und die Schneidewerkzeuge bei der Konstruktion unterstützt.

Der Wagen wird jedoch mit Hilfe von Handrädern oder Fußpedalen bewegt. Dieses Handrad wird von einem erfahrenen Bediener bedient. Das bedeutet, dass die gesamte Bearbeitung von Handdrehmaschinen in den Händen von Menschen liegt. Sie kontrollieren und regulieren die Ausrichtung und Geschwindigkeit aller Werkzeuge. Daher ist ihre Bearbeitungsmethode zeit- und arbeitsaufwändig.

Im Gegensatz dazu verfügen CNC-Drehmaschinen über moderne Bearbeitungsmethoden. Sie enthalten die gleichen Werkzeuge wie eine manuelle Drehmaschine, werden aber nicht vom Menschen bedient. Der Mensch trägt nicht zur Formgebung oder zum Schneiden des Materials bei. Er gibt dem Computer ein Musterdesign vor.

Der Computer steuert alle anderen Aufgaben. Er weist den Schlitten mit den Schneidwerkzeugen an, sich mit kontrollierter Geschwindigkeit zu bewegen. Außerdem steuert der Computer die Schneidewerkzeuge so, dass sie bestimmte Formen präzise erzeugen. Daher ist es nicht falsch zu sagen, dass die Bearbeitungsmethode einer CNC-Drehmaschine der eines Roboters ähnelt.

3- Verarbeitungsgenauigkeit

Die Bearbeitungsgenauigkeit ist ein weiterer Faktor, der sie auszeichnet. Ehrlich gesagt, bietet eine manuelle Drehmaschine keine hohe Genauigkeit. Der Grund dafür ist, dass sie von Menschen bedient wird. Der Bediener muss das Werkstück immer wieder umpositionieren. Diese Neupositionierung beeinträchtigt die Genauigkeit. Außerdem beeinträchtigen weniger erfahrene Bediener und Ermüdung die Produktgenauigkeit.

Die CNC-Drehmaschine hingegen wird vollständig von einem Computer gesteuert. Dieses computergestützte System eliminiert jede Chance auf menschliche Fehler. Es ist mit einem fortschrittlichen Sensorsystem ausgestattet. Wenn ein Werkzeug von der korrekten Arbeitsweise abweicht, gibt dieses System sofort einen Alarm aus. Daher ist das Endprodukt präziser und genauer.

4- Installationsanforderungen

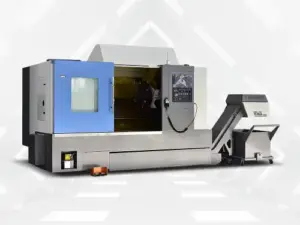

Bei der Auswahl einer Drehmaschine für Ihr Unternehmen ist die Installation ein wichtiges Kriterium. CNC-Drehmaschinen erfordern vergleichsweise komplexe Installationsverfahren. Diese Maschinen haben aufgrund ihrer fortschrittlichen Komponenten eine beträchtliche Größe. Daher wird für ihre Installation ein großer Bereich benötigt.

Außerdem verwenden sie ein computergesteuertes System. Daher ist auch ein separater Arbeitsplatz erforderlich. Denken Sie daran, dass diese CNC-Maschinen eine große Menge an Wärme erzeugen. Daher müssen Standardkühlsysteme installiert werden, um eine Überhitzung zu vermeiden.

Auf der anderen Seite sind manuelle Drehbänke sehr einfach zu installieren. Da sie keine zusätzlichen Werkzeuge benötigen, sind sie kleiner und benötigen nicht viel Platz. Ihre konventionelle Bauweise ist jedoch anfälliger für Vibrationen. Daher ist es wichtig, sie auf eine ausgewogene Plattform zu stellen. Schließlich müssen beide Arten von Drehmaschinen an einem belüfteten Ort aufgestellt werden, um effizient arbeiten zu können.

5- Anwendungsszenarien

Die Unterschiede im Aufbau und in der Funktionsweise der beiden Drehmaschinen führen dazu, dass sie in verschiedenen Bereichen unterschiedlich einsetzbar sind. Eine manuelle Drehmaschine mit einer einfachen Konstruktion stellt einfache Konstruktionsprodukte her. Sie wird zum Beispiel zum Ausbessern verschiedener gebrochener Teile von Gefäßen und Wellen verwendet. Darüber hinaus ist sie in kleinen Werkstätten, die weniger präzise Konstruktionen herstellen, üblich.

Außerdem erweist sich die manuelle Drehmaschine als hilfreich für Auszubildende in einem Fräsbetrieb. Dank ihrer einfachen Bedienung lassen sich die Grundlagen des Fräsens mühelos erlernen. Eine CNC-Drehmaschine hingegen ist speziell für die Herstellung komplexer Designs und Produkte geeignet. Sie ist eine robuste Maschine, die das Fräsen verschiedener Materialien problemlos bewältigen kann.

Daher werden CNC-Drehmaschinen für die Herstellung komplexer Gegenstände wie Kühlschränke, Boote und Teile für die Luft- und Raumfahrt verwendet. Außerdem können sie durch das Umschalten vorgegebener Anweisungen schnell viele identische Kopien herstellen. Die Genauigkeit von CNC-Drehmaschinen macht sie ideal für die Herstellung wichtiger medizinischer Geräte.

6- Investitions- und Wartungskosten

Beide Arten von Drehbänken unterscheiden sich in ihren Kosten. Die manuelle Drehmaschine bietet niedrige Anschaffungskosten. Das liegt an ihrer einfachen und traditionellen Bauweise. Sie verwendet keine komplexen Werkzeuge oder computergesteuerte Systeme, die die Wartungskosten in die Höhe treiben. Die Komponenten können zum Beispiel durch die Verwendung preiswerter Schmiermittel leicht gewartet werden.

Außerdem erfordert der einfache Aufbau keine Fachkräfte, was die Arbeitskosten senkt. All diese Faktoren machen manuelle Drehbänke kostenfreundlich. Aber denken Sie daran, dass sie für komplexe Vorgänge nicht geeignet ist. Jeder kleine Fehler bei der Bearbeitung von teurem Material kann Sie daher teuer zu stehen kommen. Im Gegensatz dazu sind CNC-Drehmaschinen relativ kostspielig.

Ihr komplexes Design, fortschrittliche Werkzeuge und computergesteuerte Systeme tragen zur Kostensteigerung bei. Darüber hinaus erhöht eine Fehlfunktion einer Komponente die Wartungskosten weiter. Die Präzision der CNC-Drehmaschine ist jedoch erstklassig. Sie sorgt für Kundenzufriedenheit und steigende Umsätze. All dies gleicht ihre Gesamtkosten aus.

CNC oder manuelle Drehmaschine: Was sollten Sie in Betracht ziehen?

Ich würde sagen, dass die Auswahl dieser Drehbänke von der Art Ihres Unternehmens oder Projekts abhängt. Eine CNC-Drehmaschine ist zum Beispiel die beste Wahl für die Bearbeitung komplexer Designs. Aber diese sind sehr teuer, was ein Nachteil ist. Umgekehrt ist eine manuelle Drehmaschine die erste Wahl, wenn Ihr Projekt einfache Entwürfe erfordert.

Es ist jedoch wichtig, beide Seiten des Bildes zu kennen, bevor man eine Entscheidung trifft. Lassen Sie mich das vereinfachen: Sowohl CNC-Drehmaschinen als auch manuelle Drehmaschinen haben Vor- und Nachteile. Eine CNC-Drehmaschine ist zum Beispiel teuer und eignet sich nicht, wenn Sie ein knappes Budget haben. Außerdem sind die Wartungskosten das Salz in der Suppe.

Was mich wirklich beeindruckt, ist seine Präzision und Genauigkeit. Wie ich bereits sagte, ist das System vollständig computergesteuert, so dass die Präzision nicht durch menschliche Bemühungen beeinträchtigt wird. Sie erhöht den Ruf Ihrer Marke und steigert die Verkaufspreise. All diese Faktoren führen dazu, dass meine Empfehlung in Richtung CNC-Drehmaschine tendiert.

Eine manuelle Drehmaschine ist eine kostengünstige Option. Sie sollten sie ohne zu zögern verwenden, wenn Sie mit dem Fräsen in kleinem Maßstab beginnen. Aber denken Sie daran, dass sie keine Präzision bei den Produkten bietet. Daher kann die Haltbarkeit der Produkte beeinträchtigt sein. Eine ordnungsgemäße Inspektion und Wartung kann jedoch das Präzisionsniveau verbessern.

Häufig gestellte Fragen

Wie lange hält eine CNC-Drehmaschine?

Die Lebensdauer einer CNC-Drehmaschine hängt hauptsächlich von ihrer Wartung ab. Eine ideale CNC-Drehmaschine hält jedoch 15-20 Jahre. Mit der richtigen Pflege kann man ihre Lebensdauer jedoch verlängern.

Warum ist eine CNC-Drehmaschine besser als eine manuelle Drehbank?

Eine CNC-Drehmaschine ist in vielerlei Hinsicht besser als eine manuelle. Dank computergesteuerter Systeme hat sie eine beispielhafte Leistung. Außerdem ist sie schnell und kann alle Arten von Materialien bearbeiten.

Wie hoch ist die monatliche Wartung einer CNC-Drehmaschine?

Die monatliche Wartung der CNC-Drehmaschine umfasst:

- Überprüfung der Leistung der Komponente.

- Auswechseln defekter Teile.

- Zusatz von Schmiermitteln

- Einbringen von Kühlmitteln.

Schlussfolgerung

Beim Fräsen werden sowohl CNC-Drehmaschinen als auch manuelle Drehmaschinen eingesetzt. Beide unterscheiden sich in verschiedenen Aspekten. Eine CNC-Drehmaschine zum Beispiel ist ein fortschrittliches Gerät, das präzise Produkte herstellt. Sie nutzt die Anweisungen des Computersystems und formt verschiedene Arten von Material effizient. Allerdings ist sie aufgrund ihrer anspruchsvollen Geometrie teuer.

Manuelle Drehmaschinen arbeiten mit konventionellen Methoden. Sie sind einfach aufgebaut und leicht zu warten. Sie wird von Menschen bedient, und es sind keine besonderen Kenntnisse erforderlich. Außerdem ist sie aufgrund ihrer Einfachheit eine kostenfreundliche Option. Ein Nachteil ist jedoch die geringe Genauigkeit der Produkte.