Lathes are incredible tools with a centuries-long history. A lathe machine works simply by rotating the workpiece around its axis to produce symmetrical objects. They are used to cut, shape, thread, drill, and polish the various materials. Its marvels have spread across multiple industries in the manufacturing field, offering unique benefits.

From the challenging aerospace industry to the delicate jewelry sector, its wide usage makes it the ultimate choice for various reasons, such as precision, accuracy, repeatability, and cost-effectiveness.

In this article, we will examine the diverse applications of lathe machines across various industries. However, let’s begin with the history of lathes and briefly discuss their types.

The beginning of Lathes

The history of laths dates back to 1300 BC, the beginning of ancient Egypt. In those days, they used manpower. One person rotated the material through the rope while the other shaped the object. With advancements, the Romans made improvements to enhance the spinning process.

In the Middle Ages, the foot pedal was a revolutionary feature that enhanced the machining process. It made work a bit easier. The Industrial Revolution brought about considerable changes. Steam engines and water wheels were introduced. Now, workers have started working with metals alongside woodworking.

By the 19th century, lathes had become a key component in factories. They allowed the creation of accurate machine parts. With technological advancements, computer-controlled lathes have become common. They have made the manufacturing process reliable and precise. They have changed the way products are produced, making customization much easier. Bulk production is cost-effective now. Yet, the working principle of lathes remains unchanged: spinning the object to manufacture.

Types of Lathes

CNC Lathe:

Computer-controlled lathes are advanced machines. They require minimal human effort, as most of the work is automated through the use of installed software. These machines are used in highly challenging fields, such as aerospace, shipbuilding, and automotive.

Swiss-Type Lathe:

Swiss-type lathes are used to machine small, precise products. Watchmakers and medical equipment manufacturers often use them.

Vertical Lathe:

Vertical lathes allow the workpiece to stand upright and are suitable for working on bulky, oddly shaped, or heavy parts. It primarily rotates wheels, large disks, and heavy components.

Wood Lathe:

Wood lathes are used primarily for shaping and carving wood. Many woodworkers use them to create bowls, furniture legs, and decorative objects.

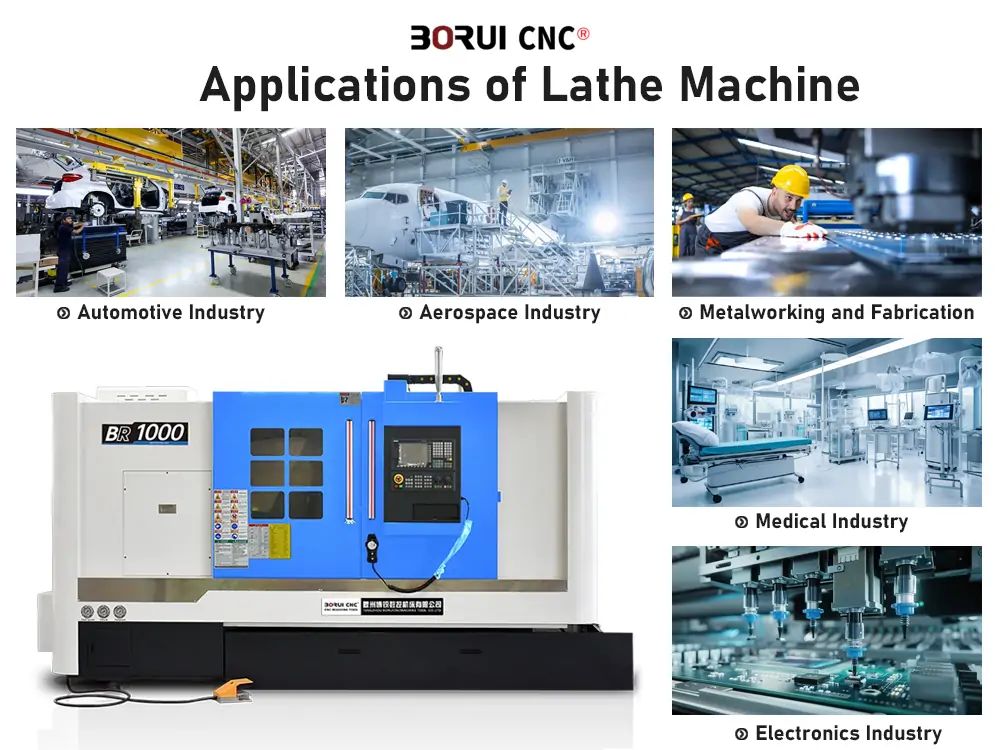

Main Applications of Lathes

Automotive Industry

Machining heavy equipment, such as cylinder liners, pistons, gears, and camshafts, depends on lathe machines. These parts must be machined efficiently at a low cost, and this is possible with the use of these incredible machines. Lathe machines enable the precise shaping of cylinders. The fitting and performance are also not compromised. Another factor is that material adaptability is vast in the automotive industry, which affects the part’s longevity. Thus, lathe machines offer various advantages in this field, such as shaping, grinding, turning, and polishing.

Luft- und Raumfahrtindustrie

The Aerospace sector is all about the involvement of advanced technology. Here, high-tech lathe machines, such as computer-controlled (CNC) versions, are used. These powerful machines are renowned for their robustness and accuracy, particularly in high-volume production runs. All the work is done with minimal human effort, thereby increasing the likelihood of human error. So you get the highest quality standard. At the same time, accuracy and precision are maintained. The machining parts include engine casings, frames, bolts, bearings, shafts, and other components.

Metalworking and Fabrication

A series of processes is involved in metalworking and fabrication, including shaping, turning, threading, polishing, and many others. So, lathes are the ultimate choice for metalworking. Engine lathes use multiple cutting tools in various steps. So, the result is precise and efficient machining.

Woodworking and Making Furniture

Raw wood pieces are transformed into various aesthetically pleasing parts in this industry. Wood furniture legs, and other wooden products such as staircases, and artistic decor pieces involve lathe machines. CNC lathe machines make an outstanding solution for these products. These machines make it a more reliable and easier choice when it comes to repeatability. This is how you get clean, precise, and accurate parts.

Producing Medical Devices

CNC Swiss-type lathes are used to machine small, thin, and precise parts for medical equipment. Medical devices must be manufactured with utmost precision, making the use of specialized lathes essential for producing equipment that saves lives.

Electronics and Precision Instruments

People in watchmaking and electronics manufacturing use both mini and micro lathes. They can build very accurate small equipment, which is important in modern electronic devices and watches.

Jewelry Making

Jewelry manufacturers use mini lathes to create metal and other types of jewelry. They shape and polish them. The tiny components of these jewelry items need accuracy to produce exact stock pieces in larger quantities. Here, lath makes a reliable tool for high-end jewelry products. Jewelry produced in these machines includes items such as pendants, earrings, rings, and others with fine and intricate designs.

Energy Sector

The energy sector is another industry of keen importance. Lathes are essential tools in nuclear, fossil fuel, and renewable energy power plants. They manufacture critical components for turbines, generators, and rotors, which must be precise to function properly. Proper machining is necessary to produce electricity from energy.

Shipbuilding and Marine Applications

Manufacturing ship parts, such as propellers and shafts, is a highly challenging process. They need to be built with perfection. Heavy-duty lathes are used to manufacture these parts. The combination of advanced features, such as a pallet system in these lathe machine tools, high spindle power, and speed, makes them exceptional tools for shipbuilding. Lathe machines enable the manufacture of precise parts with high accuracy.

Glassworking

Specialized lathes hold the glass tubing and rotate using a heat-controlled process. This is done to manufacture precise and delicate glass products without breakage. With these lathes, glass sculptures, lab equipment, glass syringes, and vials are made. They offer a cost-effective option for customization.

Defense and Military Technology

Heavy-duty lathes are important in the defense industry. They build parts for military vehicles, ships, and aircraft. Artillery and gun barrels must be machined with precision to function properly and safely.

Educational and Training Software

Lathes also serve as vital training equipment. Beyond the manufacturing field, they are more than manufacturing tools. Their Bench versions are used in schools and training centers. Students are taught about the basics. They learn the basic information, software, processes, and working of lathes. With these bench lathes, individuals can become skilled operators and find employment easily. As the use of these machines prevails, there is a great demand for highly trained operators.

Schlussfolgerung

These were some of the major uses of Lathes in the manufacturing and education sectors. From human-operated versions to advanced computer-controlled machines, lathe machines have come a long way over the centuries. Various types of lathes are utilized across different industries due to their numerous benefits. With technological progress, CNC lathes have become more accurate and efficient. They have made manufacturing quick and precise. They can be seen serving many industries. From automotive and aerospace to glass manufacturing and the energy sector, their use is widespread. Lathes work with almost every material you name. Lathes are highly valued in industry and craftsmanship due to their flexibility and dependability.