Bearbeitungszentrum ist eine Art von effizienten CNC-Werkzeugmaschinen, Öl-, Gas-, Strom-, numerische Steuerung als eine, kann eine Vielzahl von Scheibe, Platte, Schale, CAM, Schimmel und andere komplexe Teile des Werkstücks Spannen zu erreichen, kann Bohren, Fräsen, Bohren, Erweitern, Reiben, starre Gewindeschneiden und andere Prozesse Verarbeitung, so ist die ideale...

Das manuelle Schaben von Werkzeugmaschinen ist eine Art mechanische Bearbeitungsmethode, bei der die Metalloberfläche mit dem Schaber an der Werkzeugmaschine behandelt wird, um die Textur und den Glanz der Metalloberfläche zu verändern. Das manuelle Schaben von Werkzeugmaschinen wird mit mechanischen Geräten durchgeführt, und die...

In der heutigen Zeit der rasanten Entwicklung ist die numerische Steuerungstechnik in verschiedenen Bereichen zu einem unverzichtbaren Werkzeug geworden. Im Bereich des Maschinenbaus sind CNC-Drehmaschinen ein wichtiger Bestandteil der Fertigungsindustrie geworden. 30° CNC-Schrägbett-Drehmaschine CNC-Drehmaschine Bett Neigung Winkel ist 30 Grad, das ist ein...

Gewindeschneiden ist eine Bearbeitungsmethode zur Herstellung von Teilen mit Gewindeformen. In der Regel werden Gewindedrehmaschine, Gewindefräsmaschine, Gewindeschneidwerkzeug und andere Geräte für die Gewindebearbeitung verwendet. Der Prozess des Gewindeschneidens beinhaltet das Schneiden von Gewinden auf einem Werkstück, um sie in andere Teile einzupassen. Die Gewindebearbeitung wird normalerweise zur Herstellung von...

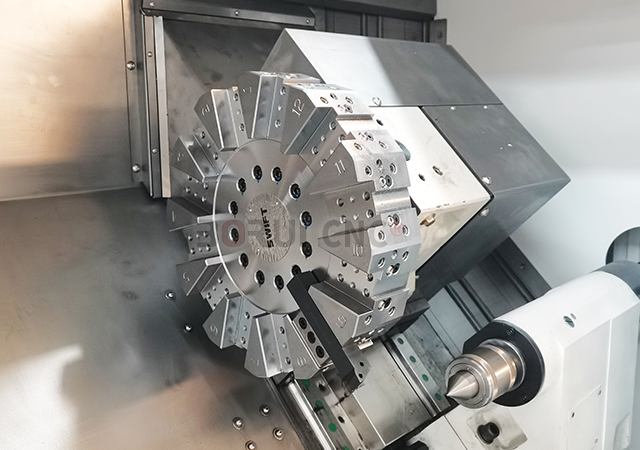

Der Revolver der CNC-Drehmaschine ist ein Teil, das zum Einspannen und Fixieren des Drehwerkzeugs verwendet wird, und besteht in der Regel aus einem Revolverkörper, einem Werkzeughalter und einer Klinge. Der Revolverkörper ist ein zylindrisches Element mit mehreren Spannlöchern, das verschiedene Arten und Spezifikationen von Werkzeughaltern einspannen kann. Der Werkzeug...

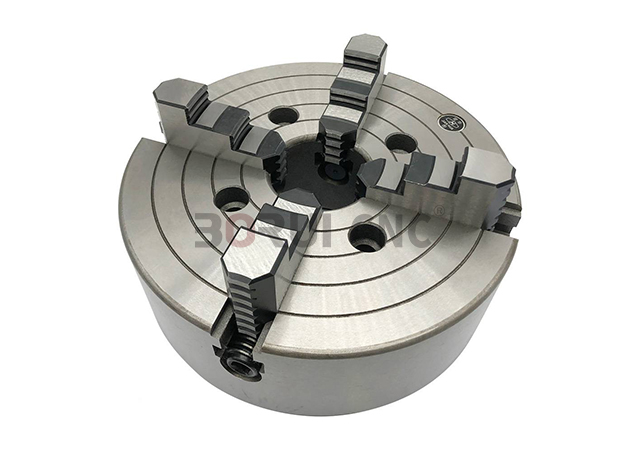

Das Spannfutter einer CNC-Drehmaschine ist ein unverzichtbarer Bestandteil der CNC-Drehbearbeitung. Es ist eine wichtige Vorrichtung zum Spannen von Werkstücken. Es ist hauptsächlich auf der Spindel der Drehmaschine installiert. Die Drehung der Spindel treibt die Drehung des Spannfutters an, um die Zerspanung durchzuführen. . Es bestimmt die Spannmethode und die Bearbeitung...

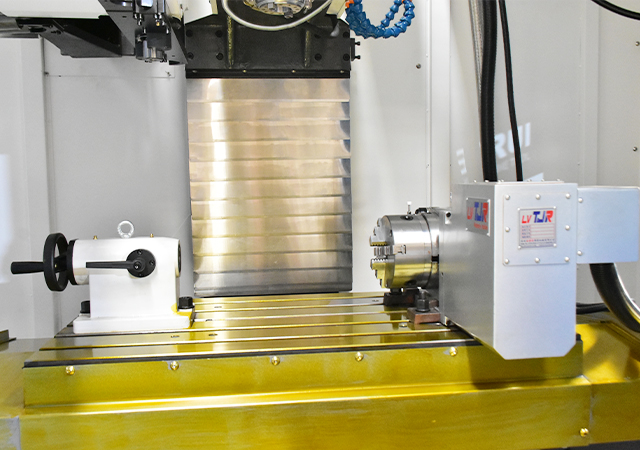

Das Vier-Achsen-Bearbeitungszentrum ist ein hochpräzises, hocheffizientes Bearbeitungsgerät, das sich in drei Richtungen (X-, Y-, Z-Achse) bewegen und positionieren kann und sich gleichzeitig drehen kann, d.h. die vierte Achse. Das Vier-Achsen-Bearbeitungszentrum ist weit verbreitet und kann zur Bearbeitung verschiedener metallischer und nichtmetallischer Werkstoffe verwendet werden, wie z.B....

Technische Beschreibung der Ausrüstung: TCK56 CNC-Drehmaschine ist eine hochsteife, kostengünstige Werkzeugmaschine, die weithin die hocheffiziente Verarbeitung von kleinen und mittelgroßen Teilen in verschiedenen Branchen wie Autos, Luft-und Raumfahrt, Formen und Instrumente erfüllen kann. Insgesamt: mechanische und elektrische Integration Design, kompakte Struktur, vernünftiges Layout, schönes Aussehen, 45° geneigtes Bett, rechteckige...

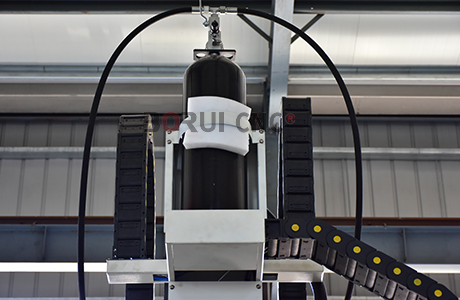

Der Stickstoffausgleichszylinder für Werkzeugmaschinen ist eine Vorrichtung, die zum Ausgleich des Stickstoffdrucks von Werkzeugmaschinen verwendet wird. Er besteht in der Regel aus einem Zylinder, der Stickstoffgas enthält, und einem Kolben, der sich in dem Zylinder bewegt. Wenn die Werkzeugmaschine Stickstoff benötigt, drückt der Kolben nach außen, um den Stickstoff in die Werkzeugmaschine zu drücken; wenn...

Vertikale CNC-Drehmaschinen sind leistungsstarke Maschinen, die zahlreiche Vorteile gegenüber herkömmlichen horizontalen Drehmaschinen bieten. Diese Maschinen sind in den letzten Jahren immer beliebter geworden, da sie mehrere einzigartige Merkmale bieten, die sie ideal für eine Vielzahl von Bearbeitungsanwendungen machen. In diesem Artikel werden wir einige der wichtigsten Vorteile von vertikalen CNC-Drehmaschinen...