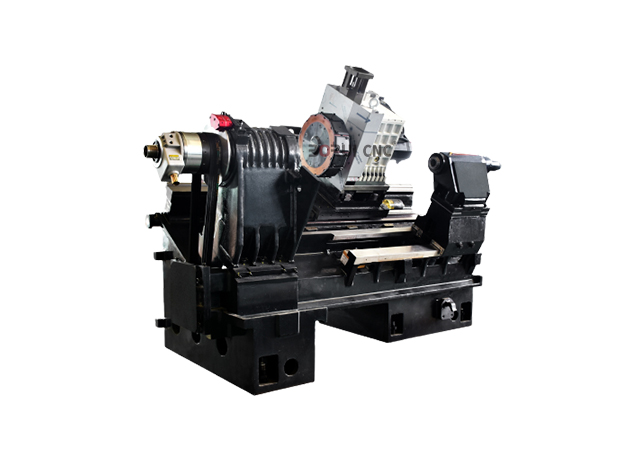

With the development of electronic technology, automatic information processing, data processing and the appearance of electronic computer, automation technology has brought a new concept, using digital signals to control the motion and machining process of CNC lathe inclined bed, promote the development of machine tool automation. CNC lathe as a kind of high precision, high efficiency automatic machine tool, is designed for mass production and processing parts of the high speed, high precision, high rigidity CNC lathe bed. Its precision is very important for machining quality.

In the process of machine tool processing, the precision of the parts processed directly affects the quality of the product, part of the machine parts and precision equipment parts of the processing precision requirements are very high, improve the machining precision of CNC machine tools is the key to solve the problem. Through extensive research and analysis, it is concluded that there are the following countermeasures to improve the machining accuracy of CNC machine tools:

In the process of machine tool processing, the precision of the parts processed directly affects the quality of the product, part of the machine parts and precision equipment parts of the processing precision requirements are very high, improve the machining precision of CNC machine tools is the key to solve the problem. Through extensive research and analysis, it is concluded that there are the following countermeasures to improve the machining accuracy of CNC machine tools.

1. Ensure The Quality Of CNC Machine Tools

Purchase CNC lathe, should choose a certain brand and reputation of the manufacturer, at the same time to carefully check the various parts of the machine tool, to improve the machining accuracy of CNC machine tools, control the original error of CNC machine tools is one of the important countermeasures. According to the standard precision adjustment, mainly from the spindle, insert and bed three aspects of adjustment, should do timely monitoring of the lathe processing process, found that a part of the deficiencies should be adjusted in time, and should observe the positioning accuracy and reverse deviation and other aspects of whether there is room for improvement, if necessary, first through manual way to correct the machine, It is further optimized by digital control. The possibility of the original error should be analyzed systematically, and the corresponding improvement measures should be formulated according to the causes and types of error. Make sure there are no quality problems.

2. Reasonably Design The Core Parts Of The Machine Tool To Avoid Positioning Errors

The positioning accuracy of machine tools has an important impact on the accuracy of parts. The core components that affect the positioning accuracy of machine tools, such as the straightness and levelness of the feed system, guide rail, working table, etc. In the design of CNC machine tools, to reasonably choose the core components, the first machine tool in accordance with the standard precision adjustment, mainly from the spindle, insert and bed three aspects of adjustment, to do timely monitoring of the lathe processing process, found that a part of the lack of should be adjusted in time, at the same time should observe the positioning accuracy and reverse deviation and other aspects of whether there is room for improvement, If necessary, the machine is corrected manually, and then further optimized by digital control. When selecting the ball screw widely used in machine tools, the accuracy of ball screw should be fully considered, and the relatively mature ball screw technology should be selected and installed.

3. Regular maintenance and maintenance

CNC lathes in the long-term use of the process, each component will appear wear and loose problems, these problems will directly affect the accuracy of CNC lathes. Therefore, regular maintenance and maintenance of CNC machine tools, timely replacement of worn parts, fastening loose parts, can effectively ensure the accuracy of CNC machine tools. Operators should strictly abide by the use of procedures, the correct operation of CNC machine tools. Operators should have certain professional knowledge and skills, abide by the operating procedures, the correct use of CNC machine tools, avoid due to misoperation and affect the accuracy of CNC machine tools

To sum up, to ensure the accuracy of CNC machine tools needs to start from many aspects, including the quality of machine tools themselves, regular maintenance and maintenance, the use of environmental attention and the professional quality of operators. Only in these aspects to ensure, to ensure the precision of CNC machine tools, improve the quality of processing.

https://www.youtube.com/watch?v=xUJrydrqkFw

Angebot anfordern