CNC-Fräsen ist ein subtraktives Fertigungsverfahren, bei dem computergesteuerte Maschinen Material von einem Block abtragen, um präzise Teile und ebene Flächen zu erzeugen. Bei diesem Verfahren wird das Werkstück auf der Maschine befestigt, wo rotierende Schneidwerkzeuge die gewünschte Form durch physikalische Verdrängung des Materials herausschneiden.

Kategorie-Archive: Uncategorized

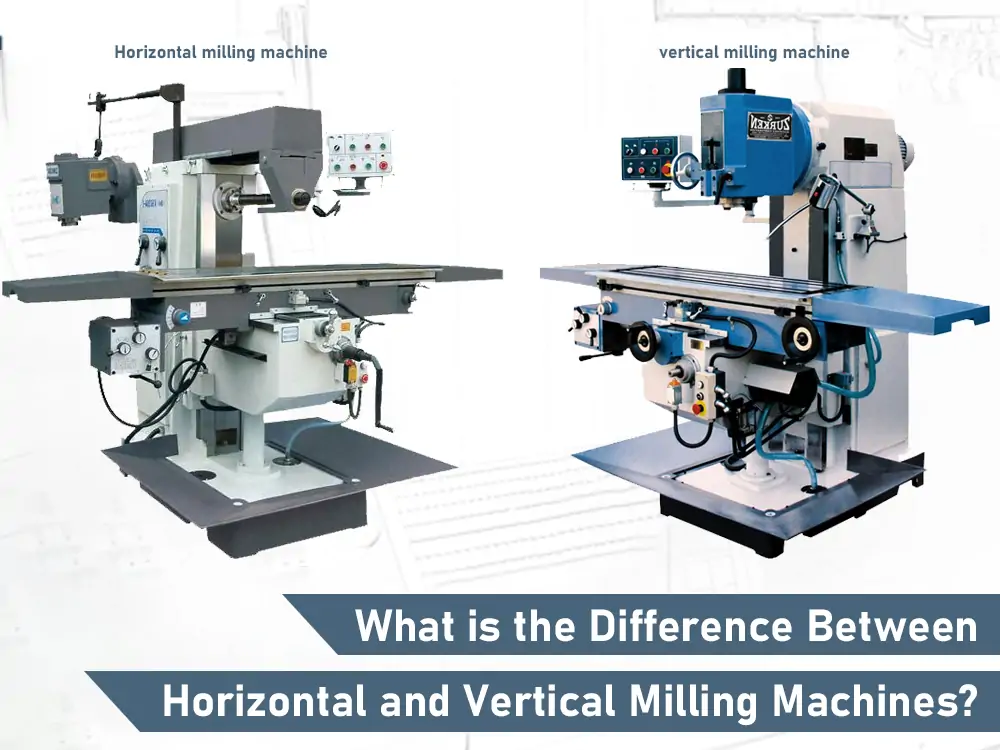

Fräsmaschinen sind wichtige Werkzeuge in der zerspanenden Industrie, die für die Bearbeitung von festen Materialien eingesetzt werden. Es gibt verschiedene Fräsmaschinen, jede mit einzigartigen Merkmalen und Anwendungen. Zu den gängigen Typen gehören Vertikalfräsmaschinen, Horizontalfräsmaschinen und Revolverfräsmaschinen. Das Verständnis der verschiedenen Arten von Fräsmaschinen ist entscheidend für die Auswahl des richtigen Werkzeugs für die jeweilige Aufgabe.

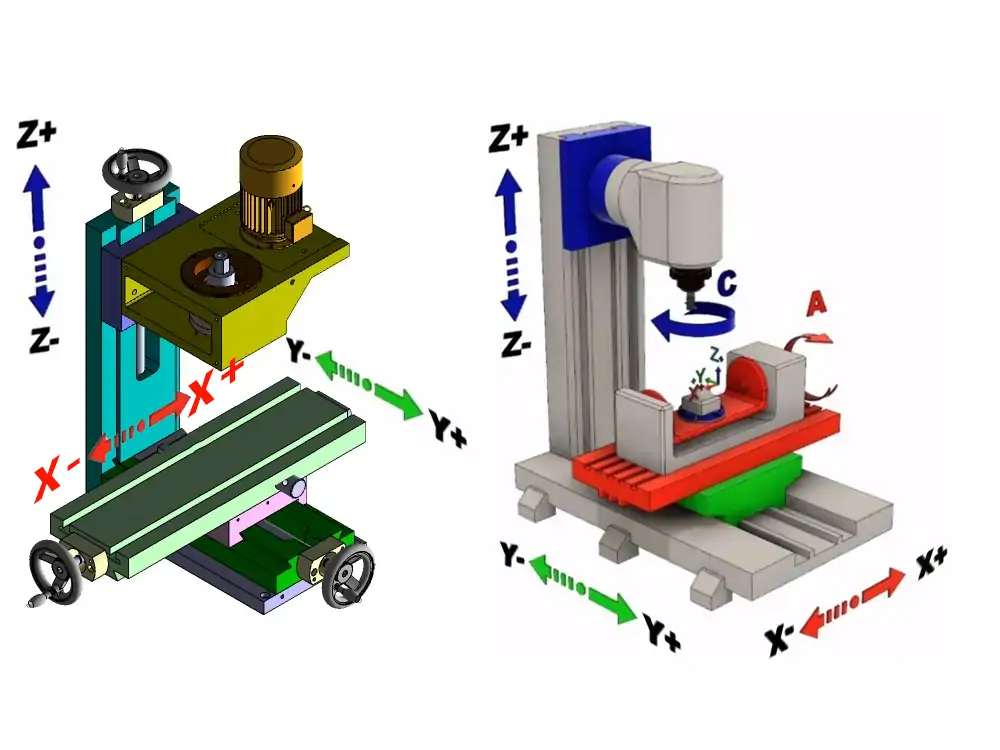

3-Achsen-Maschinen eignen sich für einfache Teile und Standardfräsarbeiten. Dies ist eine einfache, kostengünstige Lösung. Und 5-Achs-Maschinen bieten eine erweiterte Vielseitigkeit, mit der komplexe Geometrien und hochpräzise Teile mit weniger Aufspannungen hergestellt werden können.

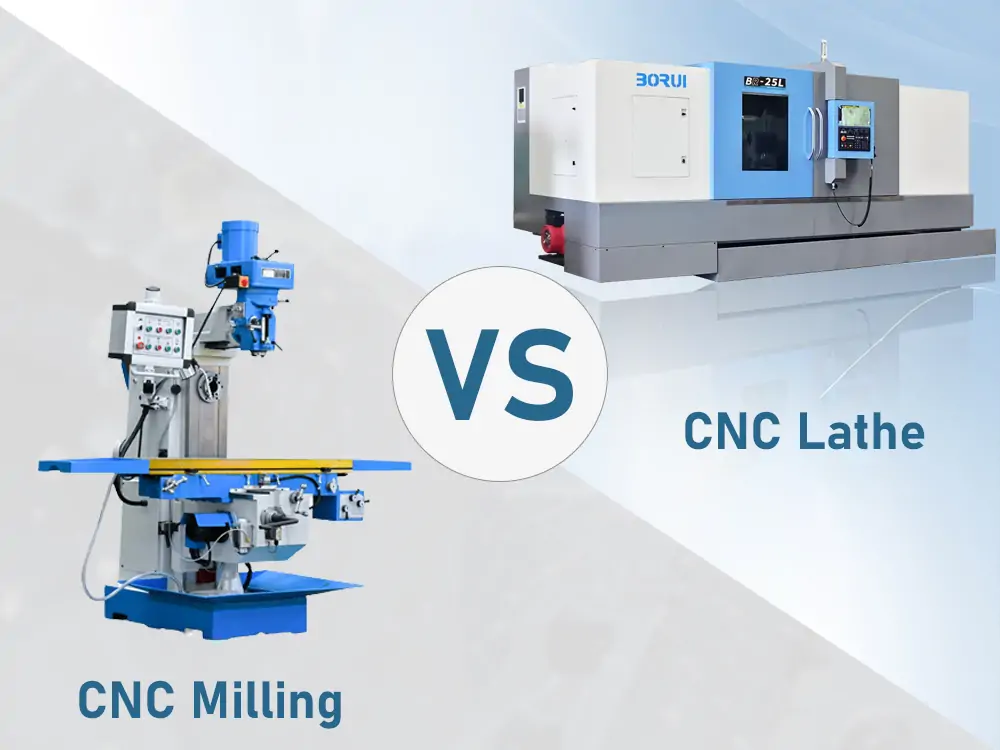

CNC-Drehen und -Fräsen sind Standardmaschinen, die in der Metallbearbeitung eingesetzt werden. Ihre Verwendung ist ähnlich, da sie zum Schneiden und Formen jedes Materials verwendet werden. Sie arbeiten jedoch unterschiedlich. Die Unterschiede zwischen CNC-Drehen und CNC-Fräsen sind sehr deutlich. Beide Werkzeuge unterscheiden sich in ihrer Arbeitsweise und ihrem Betrieb. Eine CNC-Fräsmaschine...

Sie wollen CNC-Horizontal-Bearbeitungszentren kaufen? Oder sind Sie jetzt daran interessiert? Wenn Sie sich für ein CNC-Horizontal-Bearbeitungszentrum entscheiden, müssen Sie sich für einen geeigneten Hersteller entscheiden. Die besten Hersteller von CNC-Horizontal-Bearbeitungszentren spielen eine wichtige Rolle in der Fertigung. Sie können kritische Teile und Komponenten für verschiedene Branchen auf der ganzen Welt liefern....

In der Metallverarbeitung ist das Fräsen die beliebteste Methode, um bestimmte Komponenten aus dem Material zu entfernen. Bei dieser Technik wird ein auf dem Tisch eingespanntes Werkstück mit einem schnell rotierenden Schneidwerkzeug geschnitten. Das Werkzeug kann das Material in jede gewünschte Form und Größe schneiden. Es ist möglich, eine Fräsmaschine auszurichten...

Es gibt viele verschiedene Arten von Bandsägen, die man zum Schneiden und Herstellen von Dingen verwenden kann. Jeder Bandsägentyp eignet sich für eine andere Art von Aufgaben. Die Verwendung der richtigen Bandsäge für die jeweilige Aufgabe erhöht die Sicherheit, beschleunigt die Arbeit und sorgt für einen besseren Schnitt. Du könntest...

Eine Flachbett-CNC-Drehmaschine wird hauptsächlich für schwere Dreharbeiten verwendet und kann Scheiben, kurze Wellen und komplexe Formen herstellen. Sie kann auch verschiedene Innen- und Außengewinde mit metrischen oder zölligen Werten herstellen. Auf der Flachbett-CNC-Maschine kann der Drehkopf den Rand des Werkstücks fräsen oder bohren, auch um den Rand herum. Die...

Anhand des Werkzeugmagazins können Sie erkennen, ob es sich bei einer computergesteuerten Maschine um ein CNC-Bearbeitungszentrum oder ein CNC-Fräszentrum handelt. Eine CNC-Drehmaschine (Computer Numerical Control) ist eine automatisierte Maschine, die über eine Methode zur Programmsteuerung verfügt. Wenn das Steuerungssystem das Programm liest, kann es Steuercodes verwenden oder...

Kreissägen und Bandsägen sind zwei Standardwerkzeuge in der Welt der Holz- und Metallbearbeitung. Sie spielen eine einzigartige Rolle beim Schneiden von Materialien. Beide Sägen haben ihr eigenes Design und ihre eigenen Merkmale. In verschiedenen Arbeitssituationen können sie unterschiedliche Vorteile bieten. Aber wenn Sie die Wahl hätten, würden Sie eine Kreissäge bevorzugen...