Machining center is an indispensable and important equipment in modern industrial production, and its accuracy has a crucial impact on the quality and performance of the product. Accuracy refers to the size, shape and position accuracy of the machining center in the processing process, which is directly related to the accuracy, stability and reliability of the product.

In the machining center, machining center accuracy error is not preventable, as long as the factors affecting the error to stop detailed analysis, in order to take appropriate preventive measures to reduce the machining error, improve the efficiency of the machining center. In the processing center, errors will inevitably occur, if you want to ensure work efficiency, reduce data waste, reduce labor, you should ensure and improve processing accuracy.

Machining center refers to the process of stopping the modification of the overall size or performance of the workpiece through various machines. According to the temperature state of the workpiece to be processed, it is divided into cold processing and hot processing. The process in the machining center refers to the local process that is continuously completed for one or a group of workpieces at a working place. The main characteristics of a process are that the processing object, equipment and operator are not changed, and the content of the process is continuously completed.

The precision of the machining center has an important impact on product quality, performance, production efficiency and cost. Enterprises should pay attention to the precision of the machining center, purchase and use high-precision equipment, and enhance the competitiveness of products and market share. At the same time, the manufacturer of the machining center should also continue to improve the technical level, and constantly improve the accuracy and performance of the equipment to meet the market demand for high-precision machining. Only in this way can we promote the development of industrial manufacturing and achieve rapid economic growth.

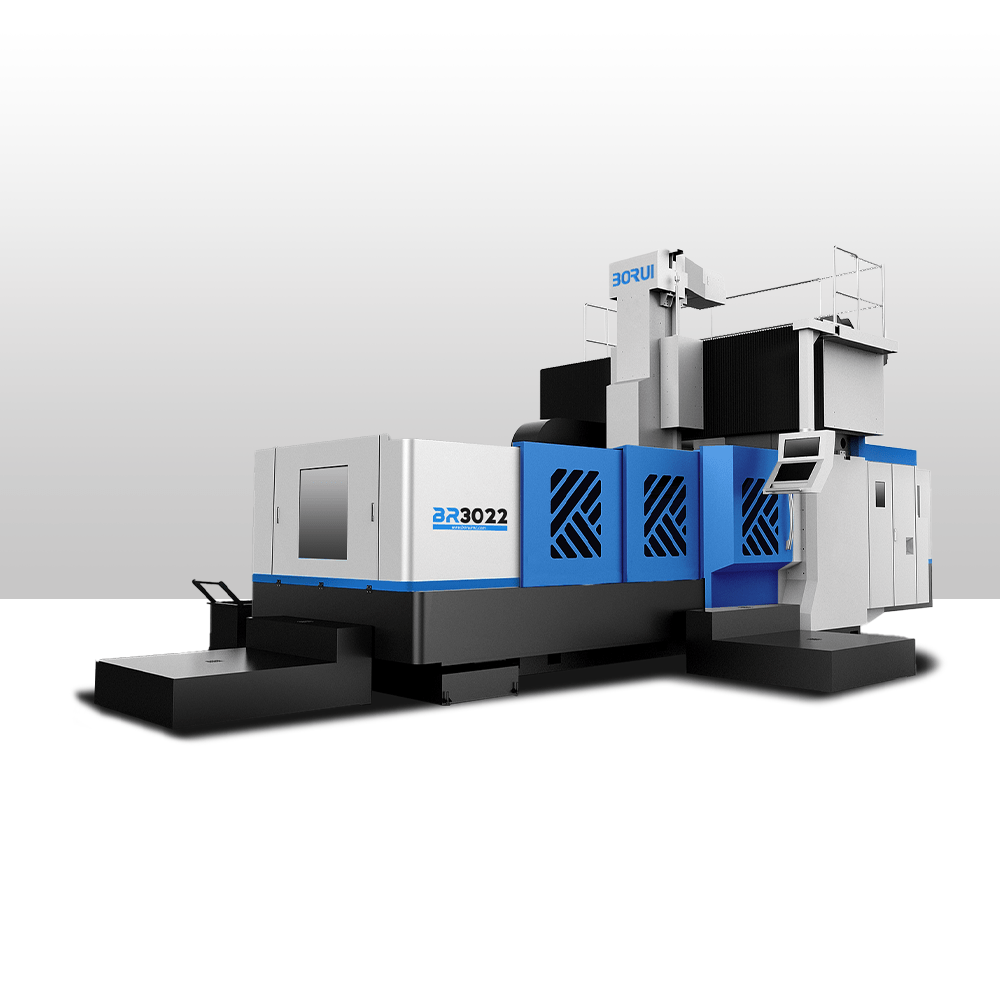

Choose High-quality Processing Center Equipment

When purchasing a processing center, you should choose well-known brands and manufacturers with good reputation to ensure the quality and performance of the equipment. It can be selected by consulting professionals and referring to user reviews.

Regular Equipment Maintenance And Maintenance

The accuracy of the machining center is affected by the degree of wear and aging of the equipment, and regular maintenance and maintenance of the equipment is essential. Regular inspection of all parts of the equipment, timely replacement of worn parts, to ensure the normal operation of the equipment and accuracy stability.

Strictly Implement The Operating Procedures

When using the machining center, the operator should operate in strict accordance with the operating procedures to avoid improper operation leading to a decrease in equipment accuracy. The operator should receive professional training, be familiar with the working principle and operation process of the equipment, and master the operation skills.

Control Processing Parameters And Process Flow

the accuracy of the machining center is affected by the processing parameters and process flow, and it is necessary to reasonably control the processing parameters and process flow to ensure the stability and consistency of the processing process. The precision of machining center can be improved by optimizing cutting parameters, selecting suitable tool and tool path, and arranging machining sequence reasonably.

Use High-precision Measuring Tools And Testing Equipment

In the processing process, it is necessary to use high-precision measuring tools and testing equipment to detect and verify the processing results. Through the accurate measurement and detection of the workpiece, the machining errors can be found and corrected in time to improve the accuracy of the machining center.

Continuously Improve The Technical Level And Equipment Performance

With the development of science and technology, the technical level and equipment performance of machining centers are also constantly improving. Enterprises should pay attention to the latest development of the industry, actively introduce advanced processing center technology and equipment, and constantly improve their own technical level and equipment performance to meet the market demand for high-precision processing.