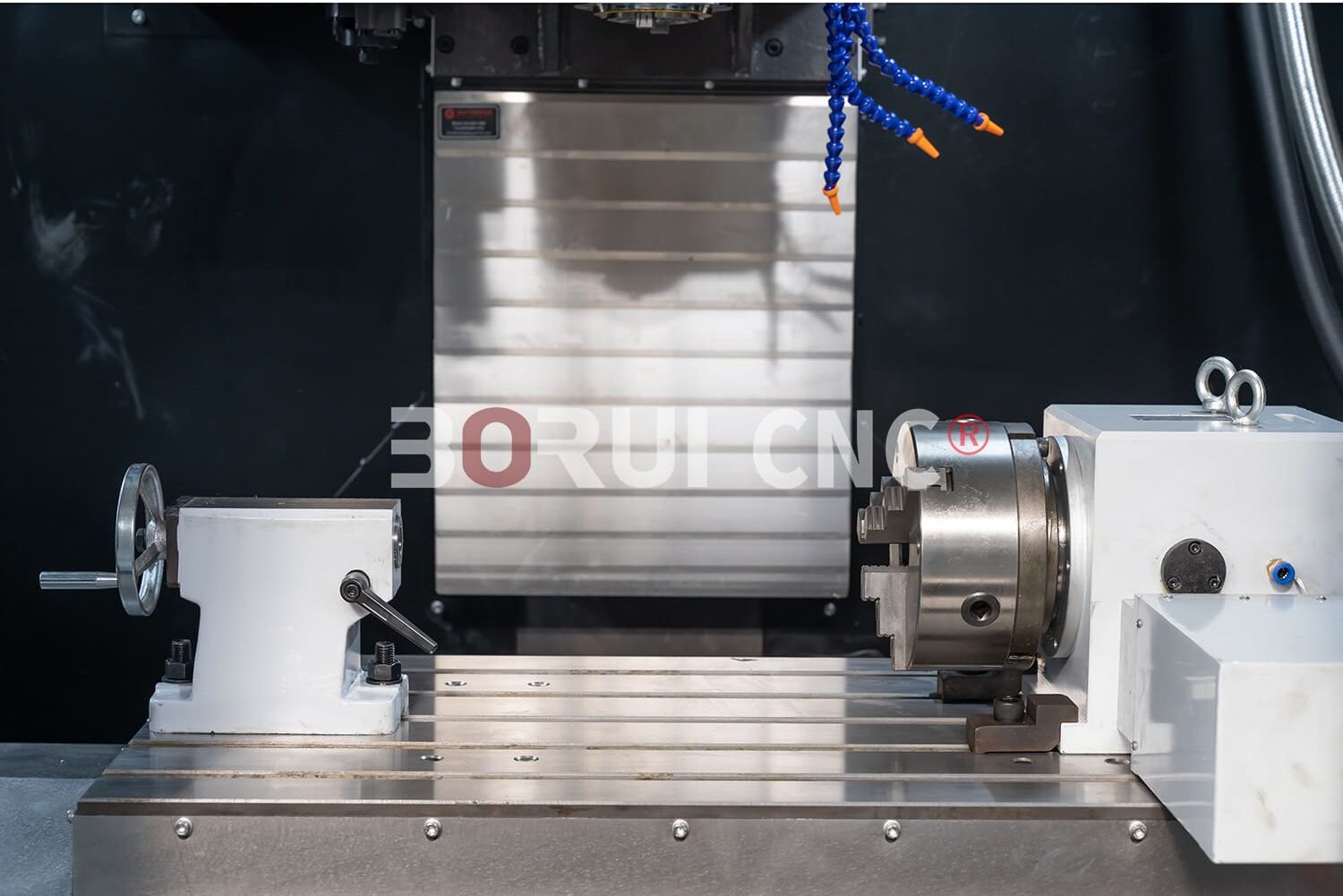

4 Achsen CNC Veritical Bearbeitungszentrum:

Nachdem die vierte Achse auf der Werkzeugmaschine des Bearbeitungszentrums installiert ist, wird sie gewöhnlich als vierachsiges CNC-Bearbeitungszentrum bezeichnet. Es realisiert die facettenreiche Bearbeitung des bearbeiteten Produkts durch die Rotation der vierten Achse oder der vierten Achse Brückenplatte, die nicht nur die Probleme überwindet, die die dreiachsige Werkzeugmaschine nicht abschließen kann. Die Bearbeitung verbessert auch die Bearbeitungseffizienz der Werkzeugmaschine erheblich und reduziert die Anzahl der Aufspannzeiten. Steigern Sie die Effizienz des Unternehmens. Die vierte Achse des Bearbeitungszentrums bezieht sich auf den CNC-Indexierkopf des Bearbeitungszentrums. Wir bezeichnen die vierte Achse üblicherweise als CNC-Teilapparat. Der CNC-Indexierkopf ist weit verbreitet und hat viele Marken. Er hat einen guten Markteffekt und kann die Effizienz und die Verarbeitungseffizienz von Unternehmen verbessern. Derzeit ist die Bearbeitung vieler Teile und Komponenten untrennbar mit dem Vier-Achsen-Bearbeitungszentrum verbunden.

Die Vorteile des 4-Achsen CNC Veritical Bearbeitungszentrums:

Es kann die Bearbeitungsebene des Werkzeugs verbessern, das wiederholte Einspannen des Werkstücks reduzieren, die Gesamtbearbeitungsgenauigkeit des Werkstücks erheblich verbessern, den Prozess vereinfachen, die Produktionseffizienz verbessern und den Produktionszyklus verkürzen. Daher ist die Anwendung von Vier-Achsen-Bearbeitungszentren sehr umfangreich. Durch Hinzufügen einer rotierenden Welle kann der Winkelversatz zwischen dem Werkzeug und dem Werkstück erzeugt werden, der Bearbeitungsbereich kann vergrößert werden und es entstehen günstige Schnittbedingungen.