Introduction

Les machines sont généralement contrôlées par un ordinateur. Le titane et l'aluminium sont découpés à l'aide de ces machines, comme les fraiseuses CNC. Dans les grandes industries, le bois est généralement coupé à l'aide de défonceuses CNC, et dans l'industrie métallurgique, on utilise des fraiseuses CNC. Broyeurs CNC peut se déplacer selon les axes X, Y et Z, ce qui rend la machine très précise, alors que les défonceuses CNC ne peuvent faire tourner leur broche que selon les axes X et Y.

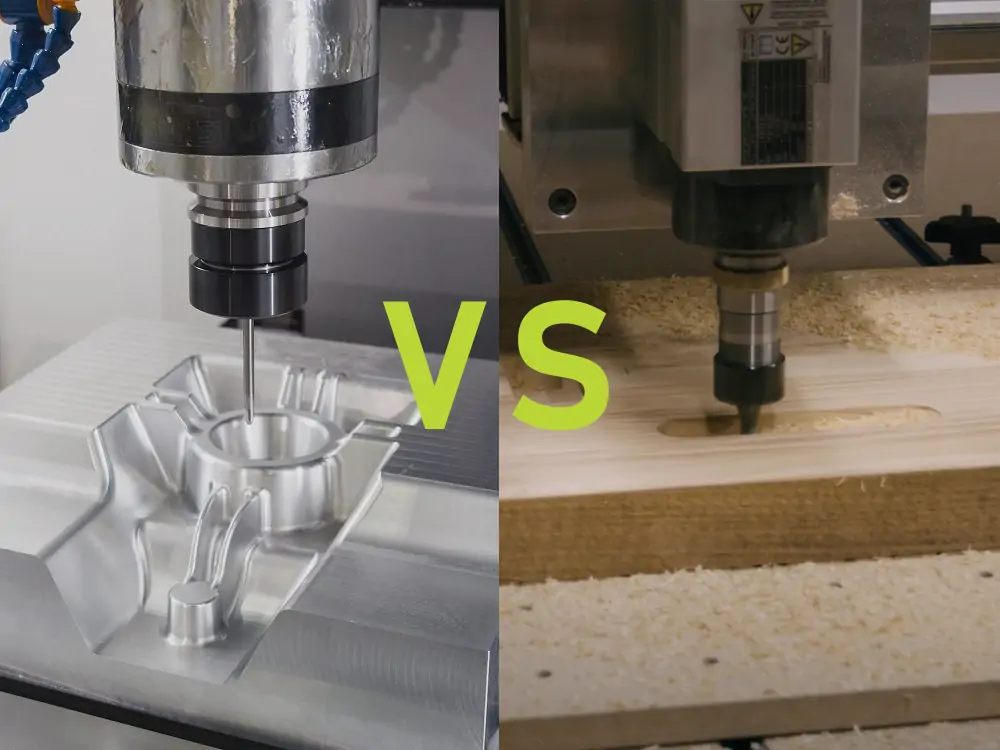

Routeur CNC vs. fraiseuse CNC

Le routeur CNC et la fraiseuse CNC sont des machines qui fonctionnent pratiquement de la même manière.

L'utilisation est différente car les défonceuses CNC découpent des matériaux souples comme le plastique, la mousse et des substances moins rigides.

Parallèlement, les fraiseuses CNC sont fabriquées dans des matériaux plus complexes, et le bois peut être coupé à l'aide de ces machines. Les industries utilisent les défonceuses CNC pour découper des matériaux à des vitesses plus élevées, tandis que les fraiseuses CNC peuvent découper des matériaux tels que le métal à des vitesses plus lentes.

| Caractéristiques de la machine | Broyeur CNC | Routeur CNC |

| Fonctionnement par ordinateur | Oui | Oui |

| Outils réglables | Oui | Oui |

| Bois et plastique comme substrat | Non | Oui |

| Outillage rigide | Oui | Non |

| Capacité d'axes multiples | Oui | Non |

| Une coupe plus rapide | Non | Oui |

- Fonctionnement d'une usine CNC

Les concepteurs de l'industrie métallurgique utilisent des ordinateurs pour les fraises CNC, d'où l'abréviation de CNC (Computer Numerical Control). Un appareil commandé par ordinateur possède une qualité qui rend le travail très précis et exact. Le dessin souhaité est obtenu en utilisant les outils rotatifs présents dans cette machine. Les fraiseuses CNC peuvent tourner sur les axes X et Y ; la conception est réalisée à l'aide d'un logiciel connu sous le nom de CAO, et la coupe est effectuée à l'aide de la fraiseuse.

- Principe de fonctionnement d'une défonceuse CNC

Un routeur CNC fonctionne de la même manière qu'une fraiseuse CNC. Il s'agit également d'un dispositif assisté par ordinateur qui peut découper le matériau selon les conceptions 2D et 3D des ingénieurs. Elle utilise la FAO (fabrication assistée par ordinateur) pour le processus de découpe. La défonceuse CNC utilise un contrôleur piloté par ordinateur qui ne nécessite pas l'aide d'un être humain. La défonceuse CNC utilise une broche qui peut tourner sur X, Y et Z.

Routeur CNC et fraiseuse - Quelle est la différence ?

Pour comprendre la différence entre une fraiseuse et un routeur CNC, il faut d'abord savoir comment fonctionne une fraiseuse. Une fraiseuse utilise une fraise rotative qui lisse la surface. Les ouvriers enlèvent de la matière de la surface de la pièce à l'aide de fraiseuses CNC. Des industries telles que l'automobile et l'aérospatiale utilisent des fraiseuses CNC pour leur fabrication.

Différentes industries utilisent ces fraiseuses CNC : à colonne, à tourelle et à cadre en C. La plus courante est de conception simple, tandis que les fraiseuses à tourelle sont plus diversifiées. La plus courante est de conception simple, tandis que les fraiseuses à tourelle sont plus diversifiées, car l'ordinateur commande des machines tournantes dans n'importe quelle direction grâce à une broche. Enfin, la fraiseuse à cadre en C est la plus robuste et de nombreuses industries l'utilisent.

- Fonctionnement des fraiseuses à commande numérique

Certains matériaux présents sur la surface d'une pièce peuvent être enlevés à l'aide de fraises CNC. La fraise rotative peut aider à créer n'importe quelle forme ou conception souhaitée.

- Une table de travail est présente ; les travailleurs l'utilisent pour placer la pièce à travailler.

- La fraise est fixée à la broche et tourne à grande vitesse.

- Le matériau est ajusté contre la fraise, ce qui permet de retirer le métal de sa surface.

- Applications

Les défonceuses et fraiseuses CNC ont de nombreuses applications.

- L'usinage CNC est utilisé pour découper et fabriquer des armoires.

- Les personnes travaillant dans les industries de fabrication d'enseignes utilisent des fraiseuses.

- Les industries telles que le travail du bois utilisent ces machines pour réaliser des gravures sur le bois et d'autres surfaces.

- Différentes industries musicales utilisent ces machines pour la fabrication.

- Ces machines sont utilisées dans l'industrie du moulage.

- Matériaux

Les fraiseuses et défonceuses CNC peuvent découper ou dessiner des matériaux. Des personnes de différents secteurs peuvent utiliser les fraiseuses et les défonceuses CNC pour découper des matériaux. Les fraiseuses peuvent travailler sur différents types de matériaux.

- Les métaux tels que l'aluminium, le laiton, le cuivre et l'acier peuvent être découpés à l'aide d'une fraiseuse CNC.

- Les défonceuses CNC peuvent être utilisées pour découper le plastique et réaliser des gravures sur des surfaces souples. Les personnes travaillant dans l'industrie du plastique utilisent ces machines pour graver et découper des matériaux.

- Le bois peut être conçu à l'aide d'une fraiseuse CNC.

- Des matériaux tels que la céramique et les pierres peuvent être découpés à l'aide de ces machines.

- Les matériaux composites tels que la fibre de verre peuvent être gravés à l'aide de ces machines.

- Vitesse, puissance et rigidité

La répartition des différences entre les fraiseuses et les défonceuses CNC en fonction de la vitesse, de la puissance et de la rigidité est la suivante :

- Une défonceuse CNC peut fonctionner à des vitesses élevées, tandis que les fraiseuses CNC fonctionnent à des vitesses inférieures à celles des défonceuses CNC.

- Il est courant d'analyser la capacité d'une machine à effectuer une tâche pour évaluer sa puissance. Une défonceuse CNC ne peut découper que des matériaux tendres, elle est donc moins puissante qu'une fraiseuse.

- Les métaux et les céramiques sont découpés ou conçus à l'aide des fraiseuses CNC. Une défonceuse CNC ne peut pas effectuer une telle tâche.

- Les fraiseuses et les défonceuses CNC sont dotées de pièces fixes et mobiles qui les rendent polyvalentes et capables d'effectuer de nombreuses tâches. Les pièces fixes confèrent à la machine sa solidité et sa rigidité.

- Options de l'outil

Différentes options d'outils sont disponibles à d'autres fins dans les machines. Ces options d'outils rendent l'appareil plus diversifié et lui permettent d'effectuer de nombreuses tâches, ce qui le rend approprié pour une utilisation dans de nombreuses industries.

- Les fraiseuses CNC disposent d'outils plus complexes pour la découpe et la conception de matériaux rigides tels que le métal et la céramique.

- Les matériaux souples tels que le bois, le plastique et la mousse peuvent être sculptés à l'aide de fraiseuses CNC.

- Différents types d'outils, tels que les outils de meulage, de tournage, de fraisage et de perçage, sont disponibles.

- Coût

Le prix d'une machine dépend de son efficacité, c'est-à-dire de sa capacité à effectuer une tâche de manière efficace. Une fraiseuse CNC peut effectuer des tâches variées et complexes, c'est pourquoi son prix est plus élevé que celui d'une défonceuse CNC. Cependant, une défonceuse peut exécuter des fonctions qui ont leur importance. Cependant, le coût du routeur CNC est faible par rapport à celui de la fraiseuse. L'installation d'une fraiseuse CNC représente un investissement de plusieurs centaines de milliers de dollars. Si l'installation d'un routeur CNC n'est pas une grosse affaire, vous pouvez facilement en installer un avec un investissement minimal. Certaines entreprises utilisent des fraiseuses CNC bricolées.

FAQ

Qu'est-ce qu'un routeur CNC ?

Un routeur CNC est une machine qui découpe, grave et conçoit des matériaux souples tels que le plastique et le bois. Elle est moins précise et ne peut pas effectuer des tâches aussi précises qu'une fraiseuse CNC. Les toupies CNC sont des machines commandées par ordinateur et installées dans de nombreux secteurs, tels que l'aérospatiale, l'automobile et le travail du bois.

Qu'est-ce qu'une usine CNC ?

Une machine appelée fraiseuse CNC peut être utilisée pour graver des matériaux tels que les métaux et les céramiques. Ces fraiseuses sont très précises. Les accessoires peuvent effectuer de nombreuses tâches différentes, telles que le fraisage, la découpe et la conception.

Pourquoi choisir une défonceuse CNC ?

Le choix d'une défonceuse CNC dépend des besoins de la personne. Si une personne doit effectuer des tâches qui ne nécessitent pas une grande précision, elle devrait installer une défonceuse CNC. Ces machines peuvent travailler sur des matériaux souples comme le plastique et même la mousse.

Pourquoi choisir une usine CNC ?

Certaines industries exigent un travail très précis, c'est pourquoi l'utilisation d'une fraiseuse CNC est la plus appropriée. Une fraiseuse CNC peut travailler de manière très délicate et précise, en fraisant différents types de matériaux. Ses outils peuvent travailler de manière très complexe et efficace. Le coût d'installation d'une telle machine étant assez élevé, une CNC ne peut être utilisée que si l'industrie exige une grande précision dans ses dessins et gravures.

Quelle est la meilleure machine pour les projets de menuiserie ?

La nécessité d'une défonceuse CNC et d'une fraiseuse CNC dépend du type de projet sur lequel la personne travaille. Une défonceuse CNC peut travailler à grande vitesse. Ces projets, comme le travail du bois, exigent de la rapidité et l'utilisation d'une défonceuse CNC permet de réduire au minimum le gaspillage de matériaux.

Les deux machines peuvent-elles traiter du métal ?

Un routeur CNC ne peut travailler qu'avec des matériaux souples comme le bois et le plastique, tandis qu'une fraiseuse CNC peut couper ou graver des métaux. Aucune des deux machines ne peut donc travailler ou transformer les métaux.

Quand faut-il choisir une défonceuse CNC et une fraiseuse CNC ?

Le choix d'une défonceuse ou d'une fraiseuse à commande numérique n'est pas une mince affaire.

- Défonceuses CNC couper ou sculpter des matériaux souples comme le plastique ou le bois. L'industrie qui traite des produits en plastique ou en bois devrait préférer l'installation d'une défonceuse CNC qui fonctionne très bien à grande vitesse.

- Broyeurs CNC sculpter, couper et graver des substances dures telles que les métaux et les céramiques. Les industries qui traitent ces matières devraient envisager d'installer une fraiseuse CNC plutôt qu'un routeur CNC.