En 2024, les 10 premiers fabricants de machines CNC sont à la pointe de l'industrie grâce à leur technologie innovante et à leurs performances supérieures. Cette liste comprend des marques mondialement reconnues pour leurs machines de pointe, leur fiabilité et leur efficacité dans divers processus de fabrication. Ces entreprises sont à la pointe de l'ingénierie de précision et proposent une large gamme de machines CNC pour répondre à divers besoins industriels. L'article met en évidence leurs principaux atouts, leurs offres de produits et leurs contributions au paysage de l'usinage CNC, fournissant ainsi des informations précieuses aux entreprises qui cherchent à investir dans des équipements CNC de qualité supérieure.

Archives par catégorie: Uncategorized

Le fraisage CNC est un processus de fabrication soustractive qui utilise des machines commandées par ordinateur pour enlever de la matière d'un bloc afin de créer des pièces précises et des surfaces planes. Le processus consiste à fixer la pièce sur la machine, où des outils de coupe rotatifs découpent la forme souhaitée en déplaçant physiquement le matériau.

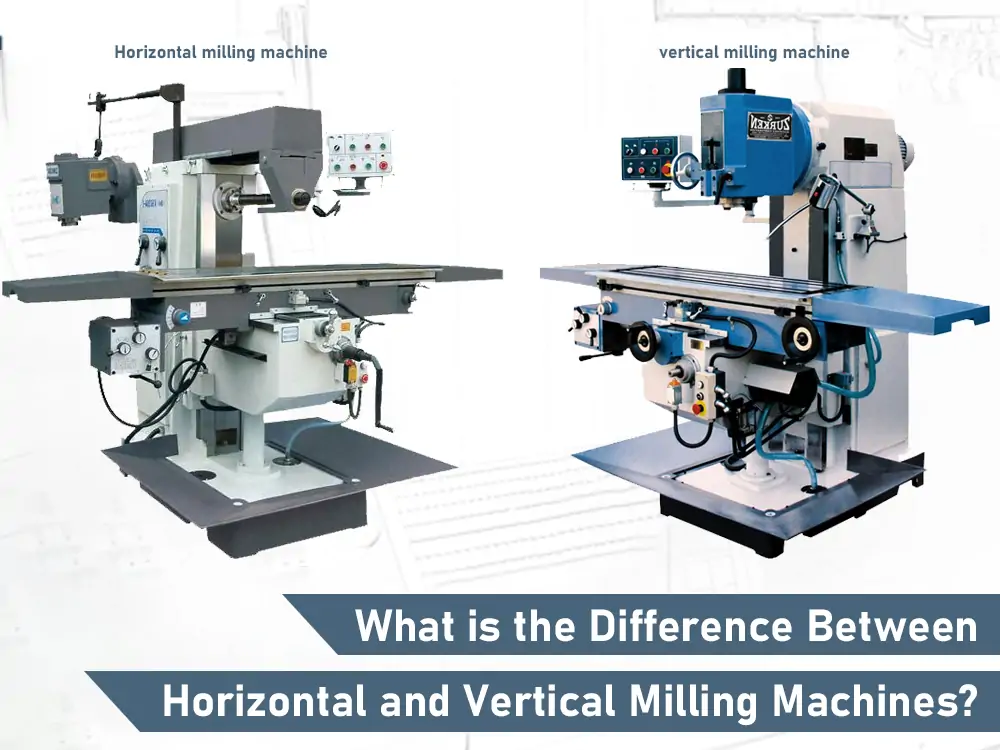

Les fraiseuses sont des outils essentiels dans l'industrie de l'usinage, utilisés pour façonner des matériaux solides. Il existe différentes fraiseuses, chacune ayant des caractéristiques et des applications uniques. Parmi les types les plus courants, on trouve les fraiseuses verticales, les fraiseuses horizontales et les fraiseuses à tourelle. Il est essentiel de comprendre les différents types de fraiseuses pour choisir l'outil adéquat.

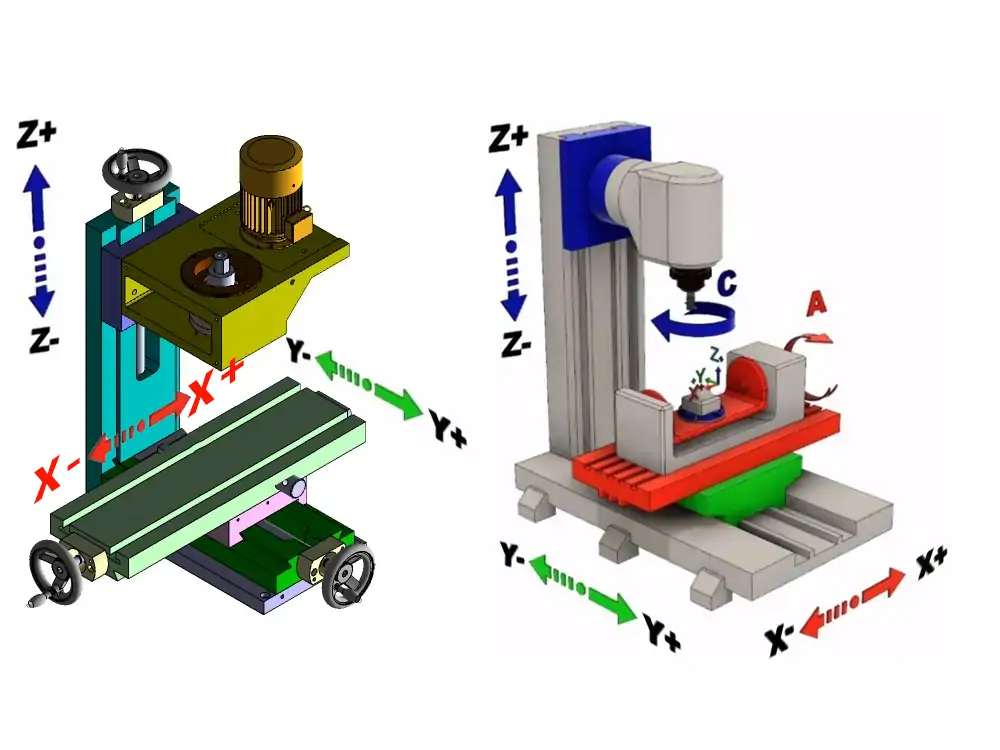

Les machines à 3 axes conviennent pour les pièces simples et les opérations de fraisage standard. Il s'agit d'une solution simple et rentable. Les machines à 5 axes offrent une polyvalence avancée, permettant de produire des géométries complexes et des pièces de haute précision avec moins de réglages.

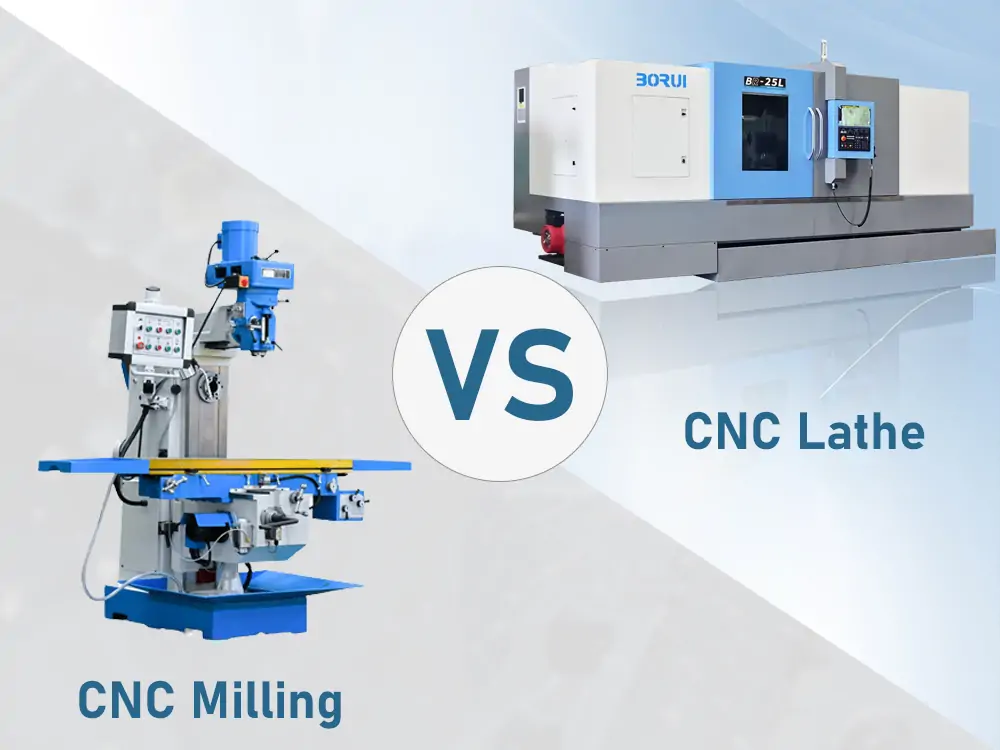

Le tour et le fraisage CNC sont des machines standard utilisées dans le travail des métaux. Leur utilisation est similaire, puisqu'elles servent à couper et à façonner n'importe quel matériau. Cependant, elles fonctionnent différemment. Les différences entre le tour CNC et le fraisage CNC sont très marquées. Ces deux outils se distinguent par leur mode de fonctionnement. Une fraiseuse CNC...

Voulez-vous acheter des centres d'usinage horizontaux CNC ? Ou êtes-vous déjà intéressé par ces centres ? Lorsque vous choisissez un centre d'usinage horizontal CNC, vous devez penser à choisir un fabricant approprié. Les meilleurs fabricants de centres d'usinage horizontaux CNC jouent un rôle essentiel dans la fabrication. Ils peuvent fournir des pièces et des composants essentiels à diverses industries dans le monde entier....

Dans le domaine de la fabrication métallique, le fraisage est la méthode la plus répandue pour retirer des composants spécifiques du matériau. Dans cette technique, une pièce serrée sur la table est découpée à l'aide d'un outil de coupe qui tourne rapidement. L'outil peut découper le matériau dans la forme et la taille souhaitées. Il est possible d'aligner une fraiseuse...

Il existe de nombreux types de scies à ruban que vous pouvez utiliser pour couper et fabriquer des objets. Chaque type de scie à ruban peut effectuer des tâches différentes. S'assurer d'utiliser la scie à ruban adaptée à la tâche à accomplir permet d'améliorer la sécurité, d'accélérer le travail et d'obtenir une meilleure coupe. Vous pourriez...

Un tour CNC à plat est principalement utilisé pour le tournage de pièces lourdes et peut fabriquer des disques, des arbres courts et des formes complexes. Il peut également réaliser différents filetages internes et externes de valeurs métriques ou impériales. Lorsqu'elle est placée sur la machine CNC à plateau, la tête rotative peut fraiser ou percer le bord de la pièce et son pourtour. Le...

Le magasin d'outils permet de déterminer si une machine à commande numérique par ordinateur (CNC) est un centre d'usinage CNC ou un centre de fraisage CNC. Un tour à commande numérique par ordinateur (CNC) est une machine automatisée dotée d'une méthode de contrôle des programmes. Lorsque le système de commande lit le programme, il peut utiliser des codes de...