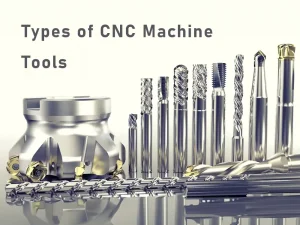

La technologie remplace de nombreuses idées et machines conventionnelles. Les machines à commande numérique sont également le résultat de révolutions technologiques. Ces machines se distinguent dans les industries manufacturières par leur rapidité et leur précision. Ces machines ont différents composants qui donnent naissance à différents types de machines-outils CNC.

Ces outils contribuent à gérer le fonctionnement précis de ces machines. Tous les types d'outils accomplissent des tâches spécifiques. Il est donc essentiel de comprendre chaque type d'outil pour obtenir les résultats escomptés. Vous ne connaissez pas ces outils ? Ne vous inquiétez pas ! Ce guide vous fournira des informations sur ces outils pour tous les types de machines, des plus petites aux plus grandes. Commençons donc.

Aperçu des machines-outils à commande numérique

Les machines à commande numérique fonctionnent à l'aide d'un ordinateur. Elles sont utilisées pour couper, concevoir et façonner différents matériaux avec une précision de 100%. Elles se composent d'un système CNC (Computerized Numerical Control) dédié. Ce système garantit que ces machines fonctionnent selon les instructions codées fournies par l'opérateur.

Vous avez certainement vu des meubles au design extraordinaire. C'est possible grâce à ces machines avancées. Mais ces machines ne fonctionnent pas seules. Au contraire, leur fonctionnement et leur fonctionnalité dépendent des outils. En termes simples, nous pouvons dire que ces machines ont des mains pour effectuer des tâches particulières, connues sous le nom d'outils.

Ces outils comprennent des outils de tournage, de coupe, de perçage et de rectification. Tous ces outils sont fixés à la structure de la machine primaire. Comment ces outils fonctionnent-ils avec les machines CNC ? Les fabricants préparent le modèle de conception à l'aide d'un logiciel. Cependant, l'ordinateur ne peut pas voir cette conception réalisée par le logiciel.

L'opérateur transforme donc ce dessin en instructions programmées. Ces instructions sont transmises à l'ordinateur. L'ordinateur décode les messages et guide les outils de coupe et de façonnage. Les outils de coupe de ces machines CNC suivent ces instructions. C'est ce qui rend leur travail extrêmement précis et exact.

Les machines CNC ne peuvent fonctionner qu'avec ces outils. En outre, ces machines s'effondrent si les outils ne suivent pas les instructions informatisées. Il existe différents outils qui améliorent la fonctionnalité de ces machines. Chaque outil permet aux machines de travailler différemment et d'effectuer des tâches uniques. Dans la section ci-dessous, nous aborderons chacun de ces différents outils.

Outils de tournage CNC

Ces outils sont utilisés dans le processus de tournage CNC. La pièce à usiner se déplace dans ce processus d'usinage. Les outils de coupe coupent et façonnent cette pièce en rotation. N'oubliez pas que le système informatisé contrôle la rotation de la pièce. De même, les outils de tournage suivent les instructions automatisées.

Ils enlèvent le matériau de la pièce avec précision. Ces outils de tournage CNC sont fabriqués dans un matériau solide. Ils sont suffisamment solides pour couper et façonner n'importe quelle pièce. Il existe différents outils de tournage. Chacun d'entre eux varie en termes de travail. Entrons dans le vif du sujet et examinons ces différents outils de tournage CNC en détail.

1- Outils d'alésage

Les outils d'alésage sont pratiques pour augmenter le diamètre d'un trou. Supposons que vous ayez percé un trou dans une pièce. Mais ce trou a un diamètre spécifique. Si vous avez besoin d'un diamètre plus important, vous devez utiliser ces outils d'alésage. Ces outils permettent non seulement d'agrandir le trou, mais aussi de le polir correctement. Il en existe deux types : les outils d'alésage grossier et les outils d'alésage fin.

2- Outils de chanfreinage

Comme leur nom l'indique, les outils de chanfreinage créent des chanfreins pour les pièces à usiner. Ces outils coupent la pièce en biais. Grâce à cet angle, la surface des pièces devient très lisse. Vous ne connaissez pas le chanfreinage ? Il s'agit d'un processus qui comprend le lissage des arêtes vives de la pièce. Il s'agit d'une étape cruciale du processus de fraisage.

Pourquoi ? Parce que les arêtes vives peuvent causer des dommages et diminuer l'aspect esthétique. N'oubliez pas que ces outils de chanfreinage existent en différentes tailles. Les outils de petite taille conviennent à un usage courant. En revanche, les outils plus grands sont utilisés à un niveau professionnel. Les fabricants les utilisent pour fabriquer des pièces afin de faciliter leur assemblage.

3- Outils de moletage

Les outils de moletage sont utilisés pour créer différents types de motifs sur le lieu de travail. Ces outils ont deux types de motifs : diamant et droit. Lorsqu'il est pressé sur la pièce, l'outil imprime le motif souhaité parmi ces deux types. Ce motif améliore le pouvoir de préhension du matériau et son esthétique. N'oubliez pas que ces outils sont très rigides et robustes. Ils peuvent donc créer des motifs et des surfaces texturées dans n'importe quel matériau.

4- Outils de séparation

Les outils de séparation sont utilisés pour détacher la partie conçue de la pièce. Ils sont constitués de lames tranchantes qui découpent la partie de la pièce. Le travail ou la coupe de ces outils est précis. Ils coupent la pièce à l'endroit indiqué par le système informatique. Il existe différents types d'outils de séparation, chacun fonctionnant différemment. Ces outils peuvent travailler avec différents matériaux, notamment le verre, le bois, le métal et les pierres.

Outils de coupe CNC

Les outils de coupe CNC sont d'autres éléments essentiels du processus de fraisage CNC. Contrairement aux outils de réglage, les outils de coupe ne restent pas immobiles pendant le fraisage. Ces outils se déplacent dans un mouvement circulaire pour couper la pièce stationnaire. L'opérateur place la pièce sur la table de travail et la serre correctement. Sa position stable permet une coupe et un façonnage précis.

L'utilisation de ces outils est standard dans les industries aérospatiale et automobile. Les fabricants les utilisent pour fabriquer différentes pièces complexes d'avions. Ils sont principalement fabriqués en carbure et en acier rapide. Ces matériaux rendent ces outils suffisamment robustes pour couper n'importe quelle pièce. Examinons quelques outils de découpe CNC.

1- Les fraises en bout de ligne

Les fraises en bout sont chargées de réaliser des fentes et des cavités et de les contourner. Elles coupent et façonnent la pièce dans différentes directions. Elles peuvent donc créer des surfaces de formes et de profondeurs variées. Vous pouvez penser que ces fraises sont similaires aux outils de perçage. Cependant, ces deux outils sont différents.

Les outils de perçage sont destinés à faire des trous. Ils sont enfoncés dans la pièce à usiner. En revanche, ces fraises sont plus polyvalentes. Elles coupent le matériau dans différentes directions, c'est-à-dire horizontalement et verticalement. Elles peuvent donc créer différents trous et fentes. Elles ne se limitent pas à la création de trous. Leurs outils de coupe peuvent réaliser des courbes dans le métal, le bois et d'autres matériaux.

2- Moulins à brames

Les fraises à brames sont utilisées lorsqu'il est nécessaire de fraiser des surfaces planes à grande échelle. Elles ont une conception complexe avec plusieurs dents pour effectuer la tâche. Ces dents sont conçues pour enlever rapidement la plus grande partie du métal de la pièce. L'utilisation des fraiseuses à brames présente toutefois certaines limites. Par exemple, elles sont moins polyvalentes en raison de leur seule géométrie horizontale possible. En outre, elles sont limitées aux surfaces planes.

3- Moulins à facettes

Les fraises à surfacer sont des outils en forme de pneu dotés de fraises spécialisées sur tout le pourtour. Ces fraises sont en carbure ou en acier rapide. Elles sont très tranchantes et rapides et peuvent couvrir une grande surface de travail. Ce que j'apprécie dans ces outils, c'est l'indépendance des fraises. Vous pouvez les remplacer en cas de dysfonctionnement, ce qui augmente la durée de vie de l'outil. Ces outils à surfacer permettent de créer facilement des rainures et d'autres formes complexes.

4- Ciseaux

Vous êtes-vous déjà interrogé sur les dessins et les formes uniques des métaux robustes ? Comment ces métaux robustes sont-ils tranchés ? Les outils de cisaillement sont à l'origine de ce travail du métal. Ces outils contiennent des lames fixes et réglables. Les lames sont suffisamment tranchantes pour couper de grandes pièces de différents métaux. L'alignement exact des cisailles est essentiel pour minimiser les déchets métalliques.

5- Moulins creux

Les fraises creuses sont spécifiques au fraisage de pièces rondes. Vous avez dû voir des boulons, des vis et des écrous. Les fraises creuses les façonnent. En outre, elles conviennent également à la création de formes cylindriques. Ce que j'aime dans ces outils, c'est qu'ils peuvent enlever de la matière à l'intérieur de la pièce. Ils permettent ainsi d'obtenir une excellente précision. La conception de ces outils est simple. Il contient des arêtes vives pour couper la circonférence de la pièce métallique ronde.

Outils de forage

Vous savez que percer signifie créer des trous. Comme leur nom l'indique, les outils de perçage CNC sont dotés de plusieurs mèches. Ces mèches sont utilisées pour percer des trous dans la pièce à usiner. Ils peuvent percer des trous dans le bois, le plastique et différents métaux. Leurs conceptions traditionnelles sont utilisées pour créer des trous un par un. Il s'agissait donc d'un processus à la fois long et peu efficace.

Aujourd'hui, les choses ont changé grâce aux progrès technologiques. Ils disposent de conceptions avancées qui leur permettent de créer de nombreux trous simultanément. Tous ces trous sont réalisés avec précision parce qu'un ordinateur guide l'outil. Vous trouverez ci-dessous plusieurs types d'outils de perçage.

1- Exercices centraux

Le type d'outil de perçage le plus simple est le foret central. Il est utilisé pour créer un petit trou de forme conique. Les fabricants utilisent ces minuscules trous comme guide pour réaliser de grands trous avec des mèches plus importantes. De cette manière, ces outils augmentent le niveau de précision du perçage. Il n'est pas faux de dire qu'ils l'utilisent principalement pour créer un repère en vue d'un perçage approfondi.

2- Forets à éjecteur

Contrairement aux forets centraux, les forets à éjecteur permettent de réaliser des trous profonds. Parfois, les forets à éjecteur sont utilisés avec les forets centraux. Par exemple, si les trous sont marqués par des forets centraux, les forets éjecteurs les rendent plus profonds. En outre, les forets éjecteurs sont dotés d'un système autonettoyant pour nettoyer les restes. Ce système s'avère très utile pour rendre le trou plus lisse.

3- Exercices de torsion

Les forets hélicoïdaux sont de petits outils de forage en forme de tige, entourés de petites goujures en spirale. Toutefois, leur arête de coupe se trouve à l'extrémité de la tige. Les cannelures servent de guide à l'arête de coupe pour percer le trou. Leur conception simple les rend populaires dans les petites industries et les ateliers. Cependant, elles surchauffent en raison de la friction due à leur utilisation pour le perçage de matériaux rigides. Des liquides de refroidissement spécifiques sont nécessaires pour y remédier, ce qui peut augmenter le coût total.

Outils de meulage

Les outils de meulage sont utilisés pour donner à la pièce un aspect final. Mais la question se pose : COMMENT ? Ces outils sont équipés de meules abrasives spécialisées. Ces meules glissent sur la pièce avec vitesse et force. Pendant le glissement, elles meulent et façonnent la pièce avec précision. Ce processus permet de réduire la surface rugueuse de la pièce.

Les pièces ne peuvent qu'acquérir une apparence délicate grâce à ces outils. De plus, il existe de nombreux types d'outils de meulage qui varient en fonction de la forme et de la taille des meules. Tous ces outils sont spécifiques à différents types de matériaux. Les outils de meulage sont précis et rentables. C'est pourquoi les fabricants les considèrent comme utiles pour le fraisage à grande échelle.

Différents types de matériaux utilisés dans la fabrication des machines-outils à commande numérique

Différents types de matériaux sont utilisés pour fabriquer des machines-outils. Une matière première de qualité médiocre donnera un outil de qualité médiocre et vice versa. Un matériau solide permet de fabriquer des outils capables de travailler avec des pièces solides. Examinons quelques matériaux courants utilisés dans les machines-outils à commande numérique.

1- Acier au carbone

L'acier au carbone est réputé pour la fabrication d'outils destinés à fraiser des matériaux tendres. Il s'agit principalement d'un alliage de métaux à faible résistance. Les outils fabriqués dans ce matériau conviennent donc au fraisage intensif. Un autre problème de ce matériau est qu'il ne résiste pas à la corrosion. C'est pourquoi des revêtements spéciaux sont appliqués pour préserver sa structure. En outre, le processus de fraisage produit une chaleur intense.

Cependant, l'acier au carbone est thermosensible en raison de son faible point de fusion. Par conséquent, les outils fabriqués en acier au carbone ne sont pas adaptés au fraisage à grande échelle. Cependant, l'un des avantages de ce matériau est sa rentabilité. Ses matières premières sont facilement disponibles et donc peu coûteuses. Si vous avez un budget serré, vous pouvez les utiliser pour de petites opérations de fraisage à petite échelle.

2- Acier rapide

L'acier rapide est réputé pour sa durabilité. Il s'agit d'un mélange de métaux robustes tels que le molybdène, le tungstène et le cobalt. Ce matériau est appelé acier rapide en raison de sa rapidité dans les opérations de fraisage. Les outils standard fabriqués à partir de ce matériau sont des outils de coupe et de forage. Il convient de rappeler que les outils fabriqués dans ce matériau sont résistants à la chaleur. En outre, les outils fabriqués en acier rapide ont une longue durée de vie grâce à leurs propriétés de réaffûtage.

3- Carbure

Le carbure est un autre matériau solide utilisé pour fabriquer des machines-outils à commande numérique. Il est formé de tungstène et de carbone, qui sont essentiels à sa dureté. N'oubliez pas que le carbure possède une capacité supérieure de résistance à la chaleur. Cela signifie que ces outils peuvent résister à la chaleur de la friction pendant le fraisage. C'est pourquoi différents outils de coupe sont fabriqués à partir de ce matériau. En outre, le carbure est également lisse, ce qui constitue un avantage pour la procédure de finition.

4- Céramique

Les céramiques sont composées d'aluminium, d'oxygène et de silicium. Ces trois composants sont responsables de leur grande solidité et de leur résistance à la corrosion. C'est pourquoi les céramiques sont utilisées dans la fabrication d'outils de coupe avancés. Les outils fabriqués en céramique ont la plus grande résistance à la chaleur de tous les éléments susmentionnés. Ils permettent donc d'effectuer des opérations lourdes.

De plus, la céramique est chimiquement inactive. Cette propriété réduit le risque de réaction avec des impuretés au cours du processus de broyage. Toutefois, il convient d'être attentif aux défauts de la céramique. Par exemple, elles sont plus fragiles et ne résistent pas à une pression élevée. Cela réduit la durée de vie de l'outil et le rend donc plus coûteux.

Facteurs à prendre en compte lors de la sélection de machines-outils à commande numérique

Lorsque vous créez une entreprise de fraisage, vous devez vous procurer des machines-outils à commande numérique. Tous les fabricants ne fournissent pas des outils de qualité égale. Les acheter de manière inconsidérée peut vous faire perdre de l'argent. Mais ne vous inquiétez pas ! Dans la section ci-dessous, je vous propose quelques listes de contrôle essentielles. Il serait préférable que vous envisagiez de choisir des machines-outils à commande numérique. Elles vous aideront à choisir les meilleurs outils pour contribuer à la réussite de votre entreprise.

1- Matériau de la pièce

Avant d'acheter des machines-outils à commande numérique, vous devez connaître la nature de la pièce à usiner. Toutes les pièces ont des surfaces et des matériaux différents. Par conséquent, les différents matériaux des pièces à usiner nécessitent différents types d'outils pour l'usinage.

Par exemple, vous devriez acheter des outils en acier au carbone si vous fraisez du plastique ou toute autre pièce souple. En revanche, pour l'usinage d'un métal à haute résistance tel que l'aluminium, il est préférable d'opter pour des outils en acier rapide. Choisir le mauvais outil pour une pièce n'est jamais une bonne idée. Les performances et la vitesse de la machine s'en trouveront affectées.

2- Matières premières de l'outil

Les machines-outils à commande numérique sont également composées de différents matériaux. Ces matériaux ont des propriétés et des caractéristiques différentes, qui sont les suivantes :

- Points forts spécifiques

- Résistance à la température

- Capacités de résistance à la pression.

Pour de meilleurs résultats, envisagez un outil qui réponde efficacement à vos critères. Par exemple, je préfère toujours un outil capable de résister à la chaleur produite par la procédure de fraisage. En outre, il convient de choisir un outil contenant des matières premières chimiquement inactives. Ces outils vous permettront d'obtenir un produit pur 100% avec une bonne durée de vie.

3- Nombre d'arêtes de coupe

Comme je l'ai mentionné plus haut, tous les outils ont des conceptions et des caractéristiques spécifiques. En outre, ils varient également en termes de nombre d'arêtes de coupe. Certains outils ont une conception conventionnelle avec moins de tranchants. À l'inverse, certains outils avancés possèdent davantage de tranchants et peuvent les remplacer. Privilégiez les outils dotés de tranchants aiguisés et excessifs. Ces outils fonctionneront efficacement et vous feront gagner du temps.

4- Type d'opération d'usinage

L'usinage CNC n'est pas une procédure en une seule étape, mais implique différentes opérations. Par exemple, le mailing comprend des processus de perçage, de coupe, d'affûtage et de lissage. Toutes ces opérations nécessitent des types d'outils spécifiques. Vous ne pouvez pas percer la pièce avec un outil de coupe. Il en va de même pour tous les outils et leurs opérations spécifiques. Par conséquent, avant d'acheter des machines-outils CNC, vous devez comprendre la nature de chaque opération.

5- Revêtement des outils

Le revêtement est appliqué pour rendre les outils plus durables. Différents types de revêtements sont appliqués sur ces outils, et ils varient en termes de nature, de prix et de résistance. Je recommande d'acheter des outils avec un revêtement en nitrure de titane. Ce revêtement est solide et augmente la longévité des outils.

Il ne fait aucun doute que les outils dotés de ces revêtements sont coûteux, mais rentables à long terme. COMMENT ? Parce qu'ils réduisent les coûts d'entretien et de réparation. Mais si vous avez un problème de budget, ne vous inquiétez pas ! Les fabricants produisent également des outils avec des revêtements en oxyde. Ces outils sont moins coûteux et bénéficient d'un traitement antirouille pendant quelques mois.

Conclusion

Cet article détaillé explique les différents types de machines-outils à commande numérique. Ces outils complètent le processus de fraisage et constituent le cœur des machines CNC. Ils présentent tous des caractéristiques, des points forts et des conceptions spécifiques. Il est essentiel de comprendre le principe de fonctionnement de chaque type avant de commencer le fraisage.

En outre, certains facteurs doivent être pris en compte avant d'acheter ces outils. Ces facteurs comprennent les matières premières, le coût, les revêtements et les arêtes de coupe. Il est essentiel de comprendre ces facteurs, car ils ont une incidence directe sur la croissance de votre entreprise. Cet article vise à vous donner une image précise de ces outils.