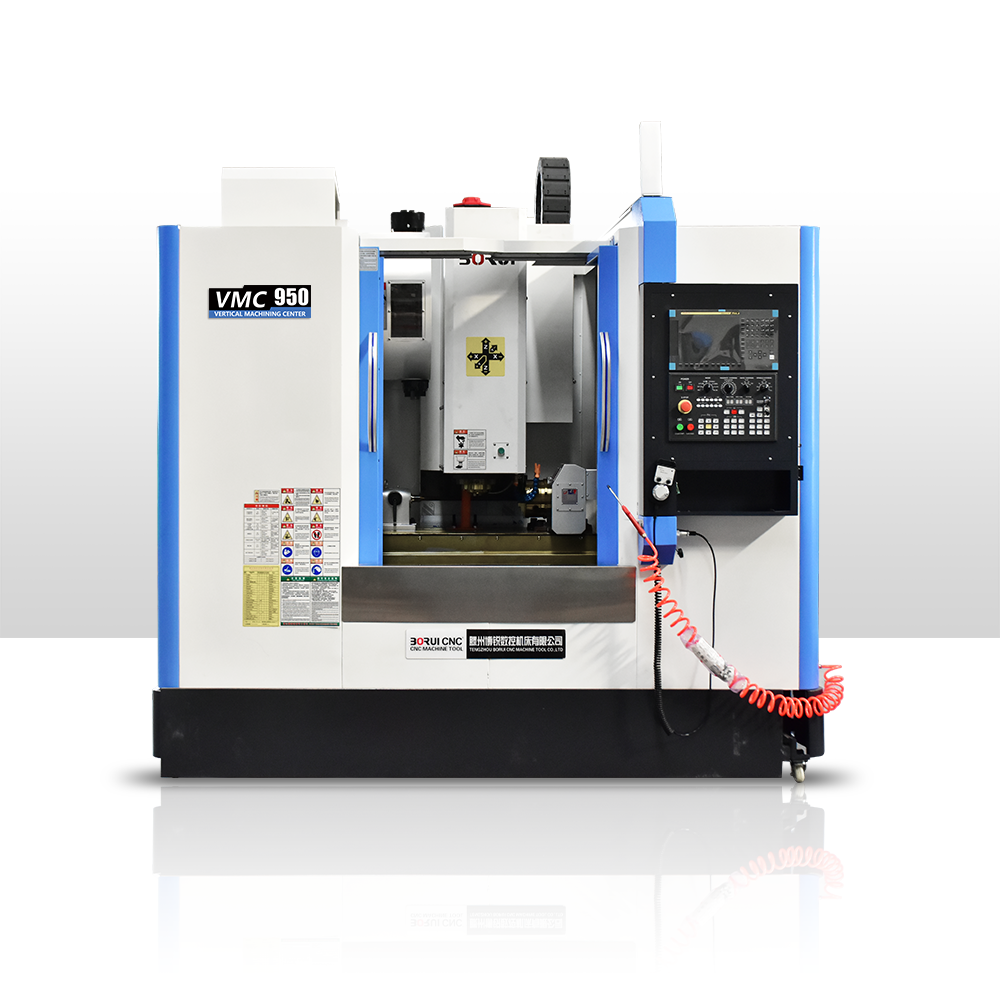

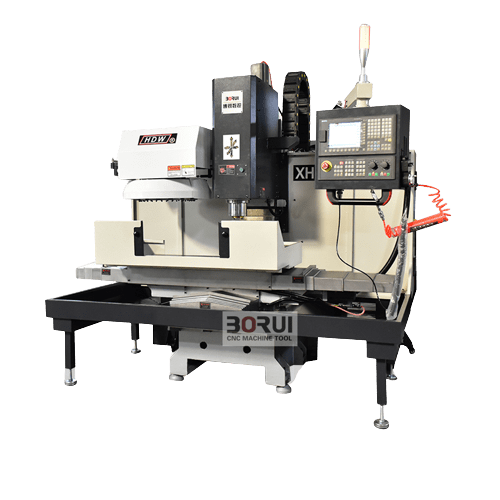

Caractéristiques du centre d'usinage vertical CNC VMC950 :

- Le corps adopte une structure tridimensionnelle à diamètre variable afin de garantir la stabilité et la fiabilité du corps, d'éviter sa déformation et d'augmenter la durée de vie de la machine-outil.

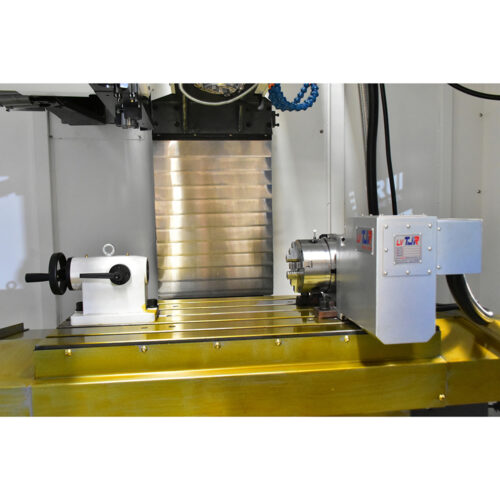

- Le siège coulissant de la machine-outil adopte une conception de type boîte, et les nervures de renforcement denses sont disposées à l'intérieur de la boîte, ce qui double la précision du corps de la machine.

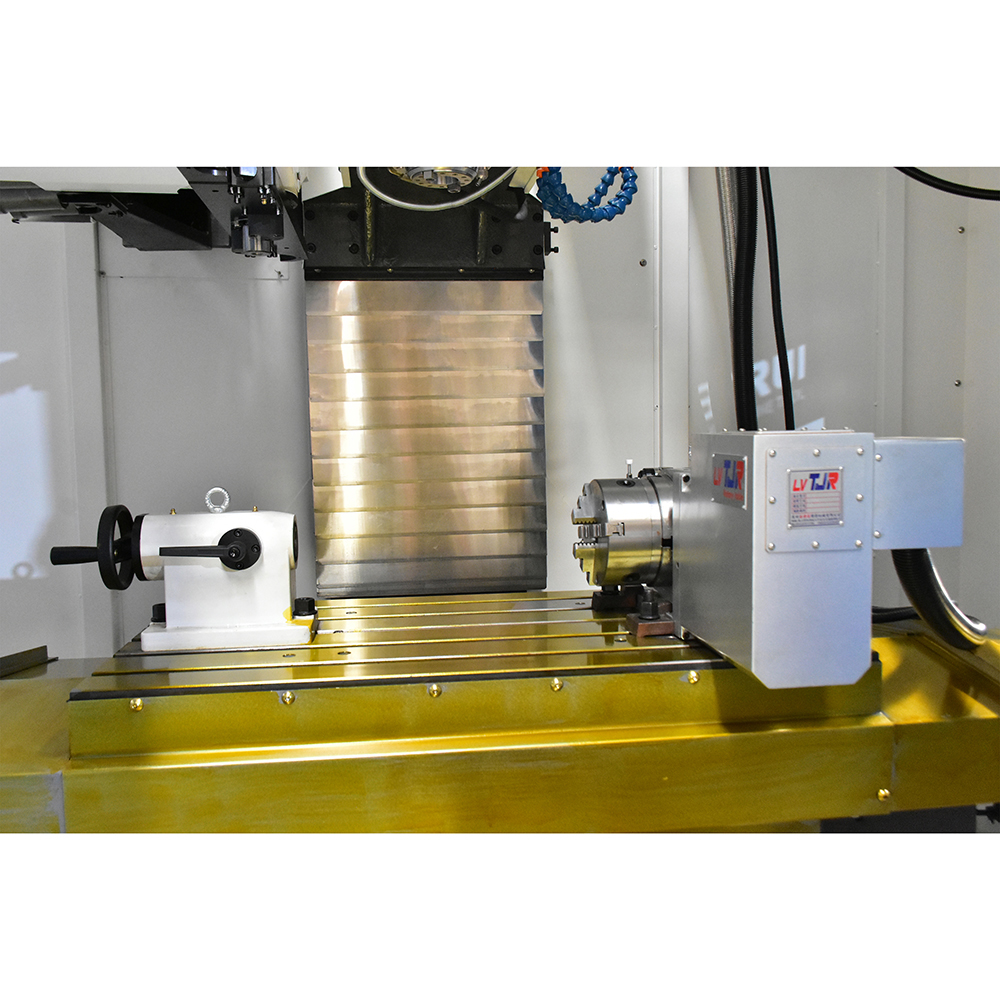

- La table de la machine-outil adopte une conception renforcée à double couche, et l'augmentation de l'épaisseur de la table masque efficacement l'interférence de l'installation du siège coulissant du guide linéaire sur la table, et améliore encore la rigidité.

- Les rails de guidage de l'axe XYZ de la machine-outil adoptent tous la méthode du grand rapport de portée, qui augmente le poids de la machine-outil dans son ensemble, améliorant ainsi la stabilité de la machine-outil.

- L'écrou de la vis à billes de la machine-outil est de conception allongée et la force de pré-serrage de l'écrou a été efficacement améliorée, ce qui prolonge considérablement la durée de vie de la machine-outil et la conservation de la précision.

- La vis à billes de la machine-outil adopte une structure d'écrou de blocage préconfigurée, qui peut empêcher efficacement le desserrage de l'écrou de blocage.

- La machine-outil adopte notre propre système de lubrification active et la pompe à huile est directement contrôlée par le système de commande numérique, ce qui permet de remplir l'huile à la demande et de détecter les problèmes causés par le circuit d'huile de la machine-outil et d'avertir les clients à temps pour éviter d'endommager la machine-outil.

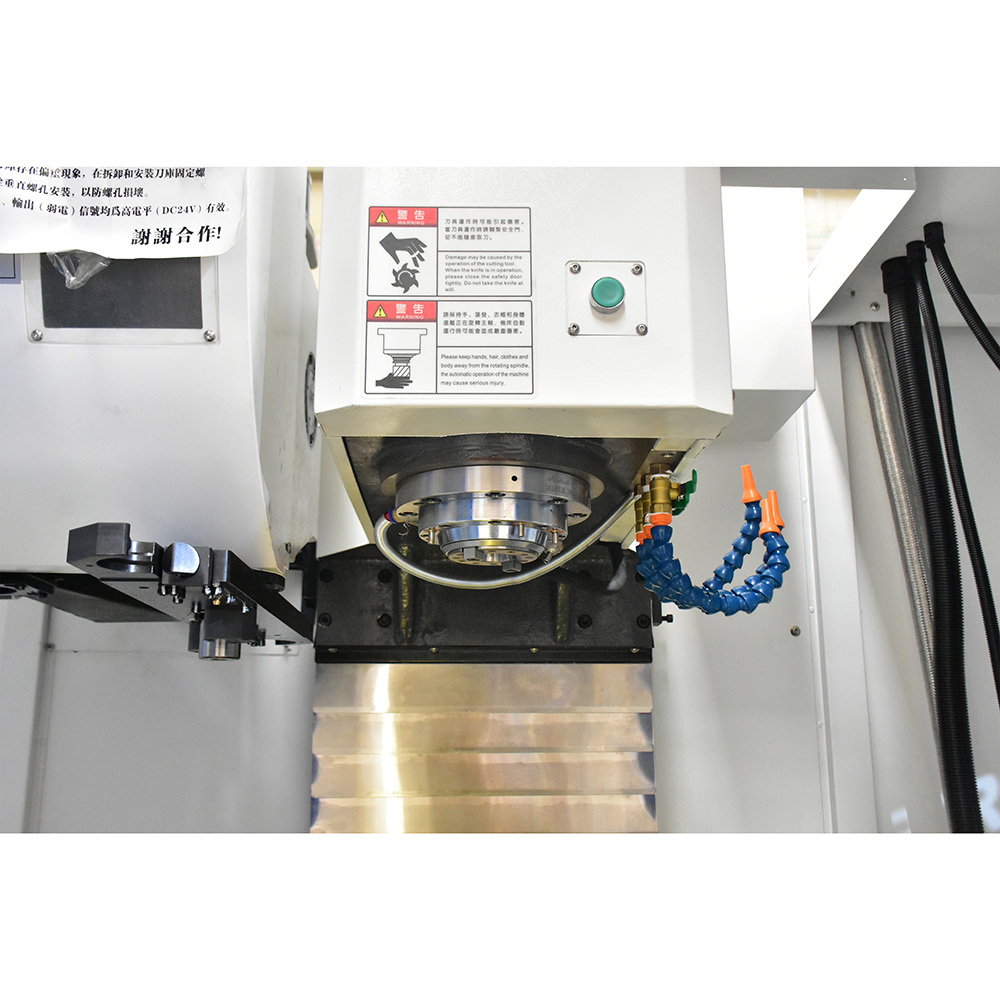

- La machine-outil adopte la conception de protection interne de la poulie de support, qui n'est pas facile à déformer et a une longue durée de vie.

- Chaque machine-outil doit correspondre précisément au poids du contrepoids de l'axe Z en fonction de l'objectif du client. Optimisation ciblée du problème entre la machine-outil et le produit fabriqué par le client.

Paramètres techniques du centre d'usinage vertical CNC VMC950 :

| Spécifications | VMC950 | |

|---|---|---|

| Course de l'axe X | mm | 900 |

| Course de l'axe Y | mm | 500 |

| Course de l'axe Z | mm | 600 |

| Distance entre le nez de la broche et la surface de la table de travail | mm | 150-750mm |

| Distance entre le centre de la broche et la surface de la colonne | mm | 560 |

| Fente en T | mm | 3-18*130 |

| Taille de la table de travail | mm | 1000*500 |

| Chargement maximal de la table de travail | kg | 600 |

| Vitesse de rotation de la broche | tr/min | 8000 |

| Moteur principal | kW | 7.5 |

| cône de la broche | BT40(Φ150) | |

| Vitesse de déplacement rapide | m/min | 24/24/20 |

| Vitesse d'avance de la coupe | mm/min | 1-10000 |

| Servomoteur à trois axes | kW | 2 * 2 *3 |

| Capacité du magasin d'outils | pcs | 24 (type de disque) |

| Taille totale de la machine | mm | 2400*2300*2580 |

| Poids de la machine | kg | 6000 |

-500x500.png)

Commentaires

Il n'y a pas encore de commentaires.