Componenti del mandrino: È il componente principale che influisce sulla precisione di lavorazione del centro di lavoro La precisione di rotazione influisce sulla precisione di lavorazione del pezzo Potenza e velocità di rotazione influiscono sull'efficienza di lavorazione Spostamenti automatici, arresti precisi e cambi utensile che influiscono sull'automazione della macchina utensile Difetti comuni del mandrino del centro di lavoro Precisione di lavorazione...

Abilità di programmazione per la lavorazione al tornio CNC su larga scala 1. La sequenza di lavorazione dei pezzi:(1) Prima la foratura e poi l'estremità piatta (per evitare il ritiro durante la foratura).(2) Prima la sgrossatura e poi la lavorazione finale (per garantire la precisione dei pezzi).(3) Prima la lavorazione delle tolleranze grandi e poi quella delle tolleranze piccole (per garantire che la superficie delle tolleranze piccole...

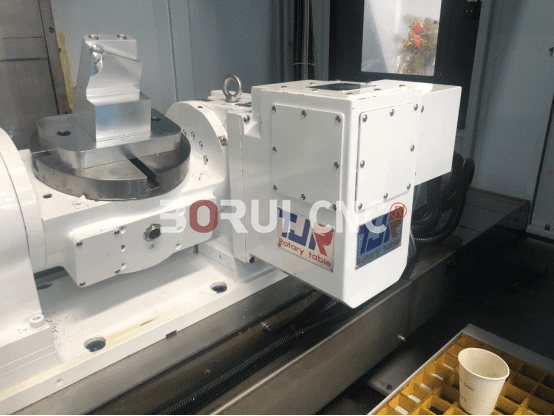

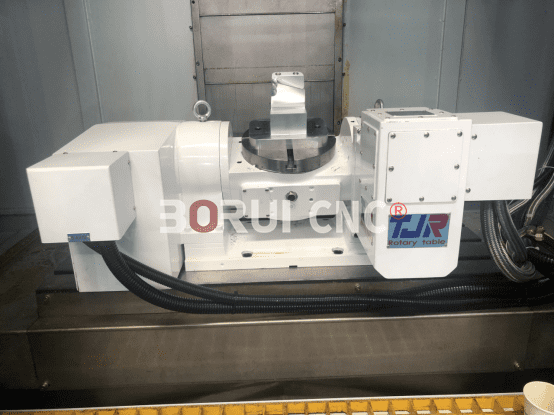

Centro di tornitura e fresatura a 5 assi Le tecniche di tornitura e fresatura a 5 assi sono tipiche delle tecniche di lavorazione multiasse. Il centro di tornitura e fresatura a 5 assi è il veicolo della tecnologia di tornitura e fresatura a 5 assi. Si riferisce alla funzione di tornitura e integra funzioni come la fresatura e la foratura, con almeno tre funzioni. Asse di avanzamento lineare della macchina...

Uno è l'asse del piatto rotante. Può essere ruotato intorno all'asse X quando è posizionato sul piano di lavoro, che è definito come asse A, e l'asse A di solito lavora in un intervallo compreso tra 30 gradi e -120 gradi. Al centro dell'orologio si trova anche una piattaforma girevole che, se ruotata intorno all'asse Z...

La scelta di un centro di lavoro verticale dipende dalla vostra situazione e dalle vostre esigenze. Ad esempio, avete bisogno di attrezzature nuove o usate per le vostre esigenze di lavorazione quotidiana? Qual è il vostro budget di capitale? Che tipo di ordini vengono gestiti in tempo reale? Quali sono i processi più qualificati o più utilizzati, e così via. Una volta che avete...

Il centro di lavoro è un tipo di attrezzatura per la lavorazione dei fori, che può essere utilizzata per varie forme di lavorazione come la foratura, l'alesatura, la maschiatura e la raschiatura delle facce finali. In base al layout di bloccaggio della macchina utensile, il centro di lavoro può essere suddiviso in centro di lavoro idraulico e centro di lavoro meccanico. Il centro di lavorazione...

1. Quale marca di centro di lavoro a 5 assi è buona? Esistono molte marche di centri di lavoro a cinque assi. Le diverse marche di centri di lavoro a cinque assi hanno un posizionamento diverso e prezzi diversi. Alcuni marchi sono posizionati nel mercato di fascia alta, come la tedesca Demagie, Hammer, la svizzera Baume, Weiliming, il Giappone. Alcuni marchi internazionali di prima linea, come Mazak e...

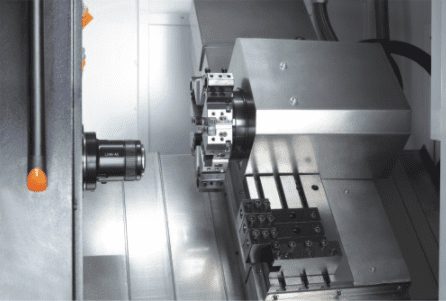

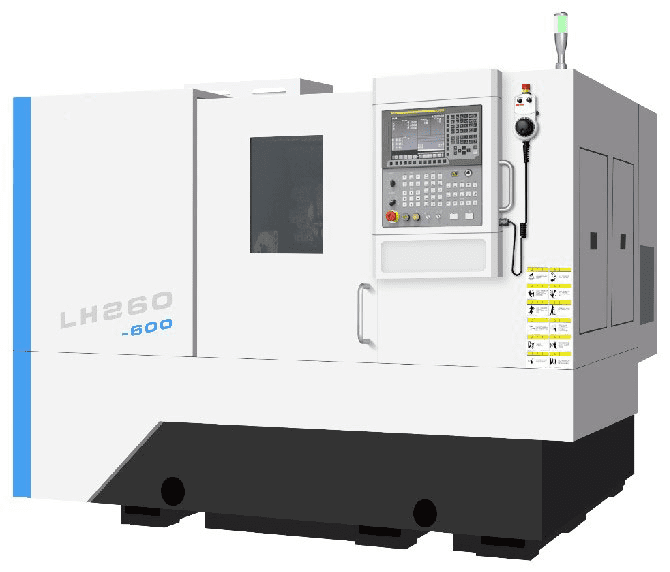

1.Posizionamento del prodotto BORUI LH260 Hardinge GS200 Il concetto di design avanzato e la tecnologia di produzione matura di BORUI LH260 hanno ulteriormente migliorato la rigidità, la precisione e la stabilità della macchina utensile e le prestazioni dell'intera macchina hanno raggiunto il livello dei marchi importati con le stesse specifiche. 2.Introduzione del prodotto-LH260 ◇ La fantina a manicotto adotta una struttura simmetrica a grande luce,...

1. La dimensione del pezzo è accurata e la finitura superficiale è scarsaRagioni: La punta dell'utensile è danneggiata e non affilata; la macchina utensile risuona e il posizionamento non è stabile; la macchina utensile presenta un fenomeno di scorrimento; la tecnologia di lavorazione non è buona.Soluzione: Dopo che l'utensile è usurato o danneggiato, non è...

VMC850 centro di lavoro verticale nell'uso del processo, a causa dell'ambiente, la temperatura, l'umidità e l'uso delle loro parti usura, la forza interna deformazione, la perdita di parti di usura e di altri fattori, le sue prestazioni complete cambierà nel tempo, l'esistenza di piccoli problemi nella macchina utensile, può portare alla...