Il tornio a banco inclinato CNC è un tipo di macchina utensile a controllo numerico computerizzato (CNC) per la lavorazione di precisione. È progettato per tagliare e modellare materiali come metalli, legno e plastica con elevata precisione e ripetibilità. In questo articolo, capiremo la struttura, i vantaggi e le applicazioni dei torni a banco inclinato CNC in...

La segatrice svolge un ruolo importante nella lavorazione industriale, il macchinario per l'intaglio mattutino produce principalmente segatrici a nastro e segatrici circolari. I produttori vogliono ordinare all'ingrosso, ma non sanno come scegliere. Di seguito, Xiaobian vi illustrerà la differenza tra la segatrice circolare e la segatrice a nastro. A...

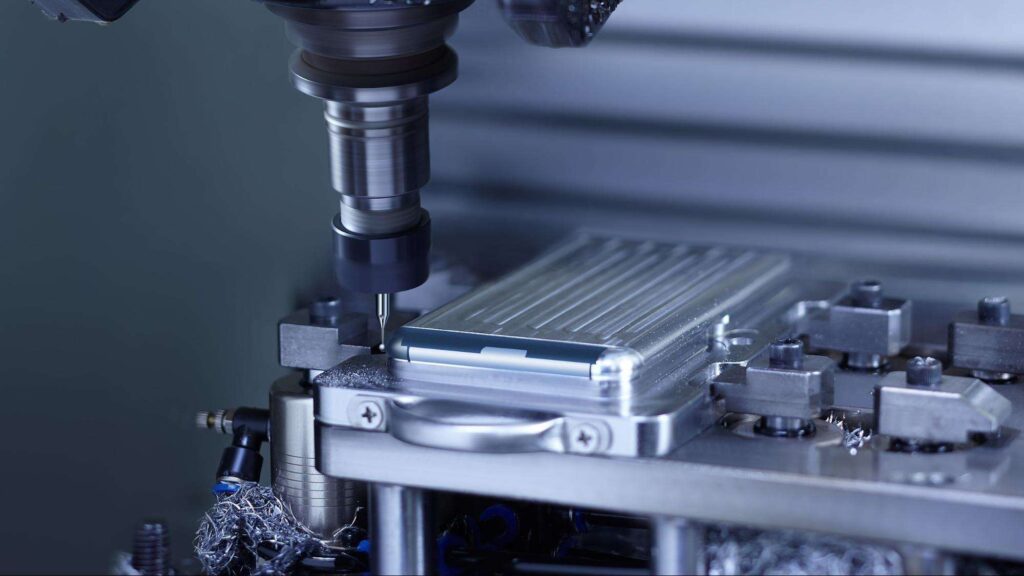

1. L'utensile utilizzato nel centro di lavoro è composto da un utensile universale (noto anche come testa di lavoro o testa dell'utensile) e da un'impugnatura che corrisponde al foro conico all'estremità anteriore del mandrino del centro di lavoro. Nell'applicazione, secondo...

Le prestazioni del sistema di controllo numerico determinano l'efficienza di lavorazione, la precisione di formatura e la stabilità di funzionamento delle macchine utensili a controllo numerico. Il sistema di controllo numerico può controllare la macchina utensile per realizzare lavorazioni a due, tre o più assi. La differenza tra il centro di lavoro e la normale macchina utensile CNC è...

Con l'applicazione del centro di lavoro a cinque assi in vari settori, aumenta anche l'argomento della lavorazione a cinque assi. Ad esempio, perché sempre più produttori tendono a utilizzare attrezzature a cinque assi per soddisfare l'alta qualità della lavorazione? Oggi diamo un'occhiata: Valore di esistenza di 5 assi: ...

Misurazione della precisione della vite di piombo: Poiché la precisione della vite di piombo è la principale precisione della macchina utensile, prima della revisione della macchina utensile è necessario controllare la precisione della vite di piombo per determinare le misure di riparazione della vite di piombo, o la riparazione, o la sostituzione. L'ispezione della vite...

L'accuratezza del cuscinetto sul mandrino della macchina utensile dovrebbe essere ISOP5 o superiore, mentre per il supporto del mandrino delle macchine utensili CNC, dei centri di lavoro e di altre macchine utensili ad alta velocità e ad alta precisione, dovrebbe essere selezionata l'accuratezza ISOP4 o superiore; i cuscinetti del mandrino includono i cuscinetti a sfere a contatto obliquo, i cuscinetti a rulli conici e i cuscinetti a rulli cilindrici....

Il centro di lavorazione Longmen è utilizzato principalmente nei settori aeronautico, aerospaziale, automobilistico, militare, dell'energia, dell'informazione, degli stampi e in altri settori di lavorazione delle parti. È progettato per lavorare parti complesse di grandi e medie dimensioni di metalli neri e non ferrosi. Ha le caratteristiche di alta precisione, alta velocità, alta flessibilità e protezione ambientale. I suoi indicatori di prestazione e...

Con lo sviluppo della moderna tecnologia di produzione, le apparecchiature di lavorazione CNC e il relativo sistema CAM sono stati ampiamente utilizzati e sviluppati. Il percorso dell'utensile di lavorazione generato dal sistema CAM (ovvero la modalità di taglio) è il fulcro del controllo delle operazioni di lavorazione dell'apparecchiatura. Il percorso di taglio è il percorso di movimento e la direzione...

Con lo sviluppo delle macchine utensili CNC in Cina, la fresatura dei filetti come metodo di utilizzo delle macchine utensili CNC per la lavorazione dei filetti è stata gradualmente accettata e apprezzata dalla maggior parte dei clienti in Cina. La fresatura di filetti viene eseguita utilizzando la funzione di collegamento a tre assi della macchina utensile del centro di lavoro NC. Il processo di fresatura dei filetti...