1.Product Positioning

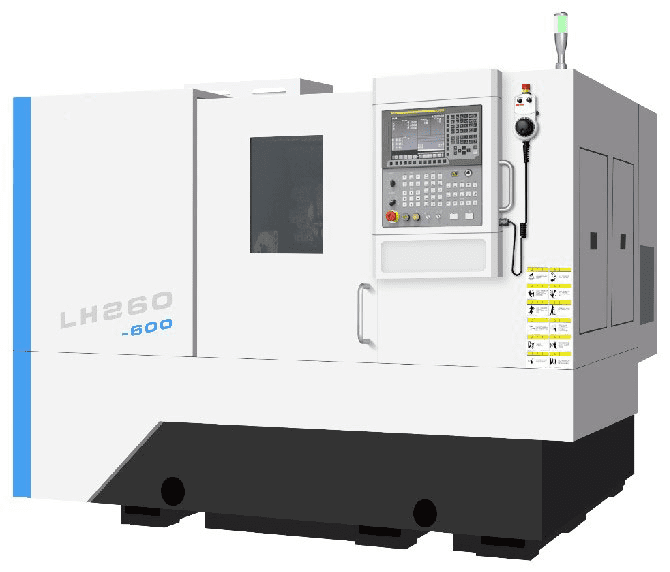

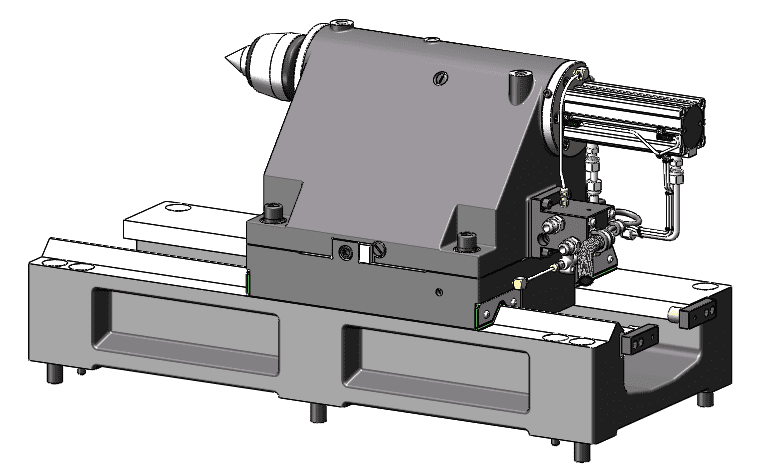

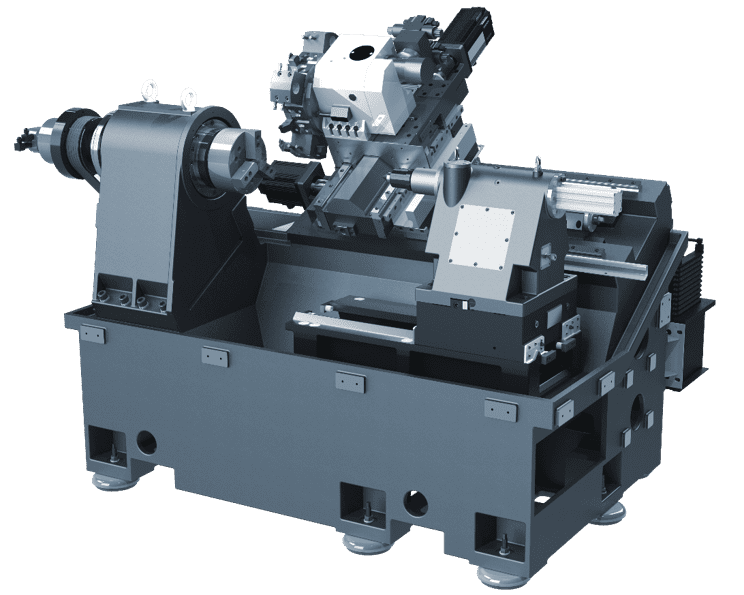

BORUI LH260

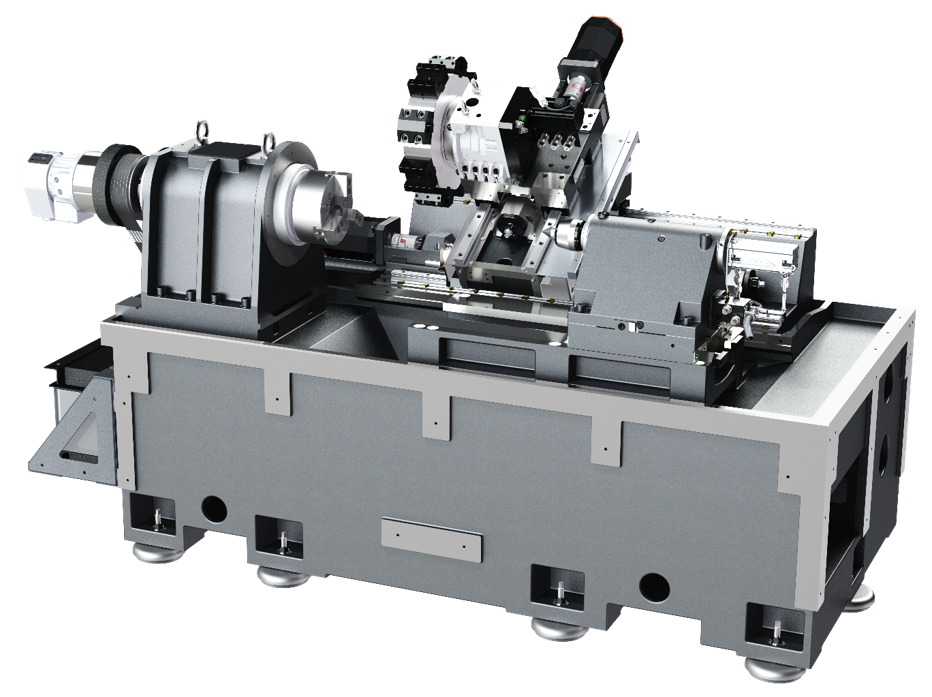

Hardinge GS200

BORUI LH260’s advanced design concept and mature manufacturing technology have further improved the rigidity, precision and stability of the machine tool, and the performance of the whole machine has reached the level of imported brands of the same specification.

2.Product Introduction—LH260

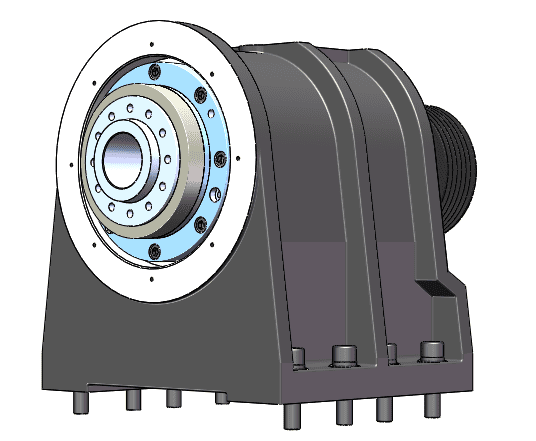

◇The sleeve-type headstock adopts a large-span symmetrical structure, with small thermal drift, stable precision and strong rigidity.

◇The headstock and the structural surface of the bed adopt the paired scraping and grinding process to ensure the contact rigidity.

◇The overall inclined bed has a stepped flat guide rail structure.

◇The whole machine adopts a unique oil-water separation design to avoid oil pollution and prolong the use time of cutting fluid.

◇Standard 8-station Taiwan hydraulic tool turret, stable and reliable work.

◇Small triangle saddle structure,Thicker in size and more rigid.

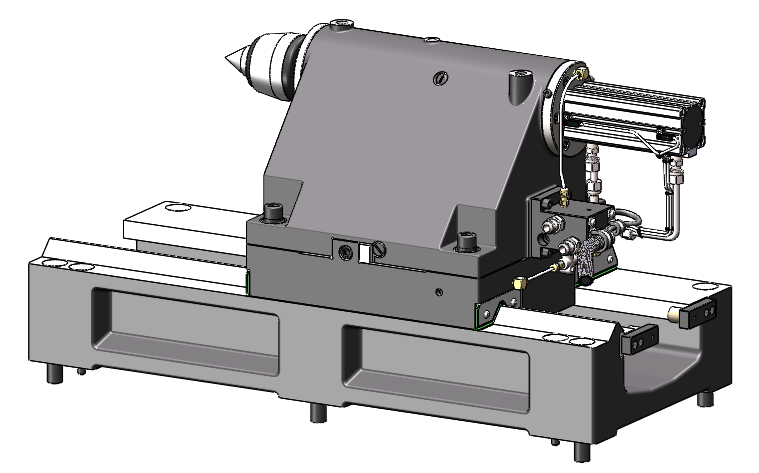

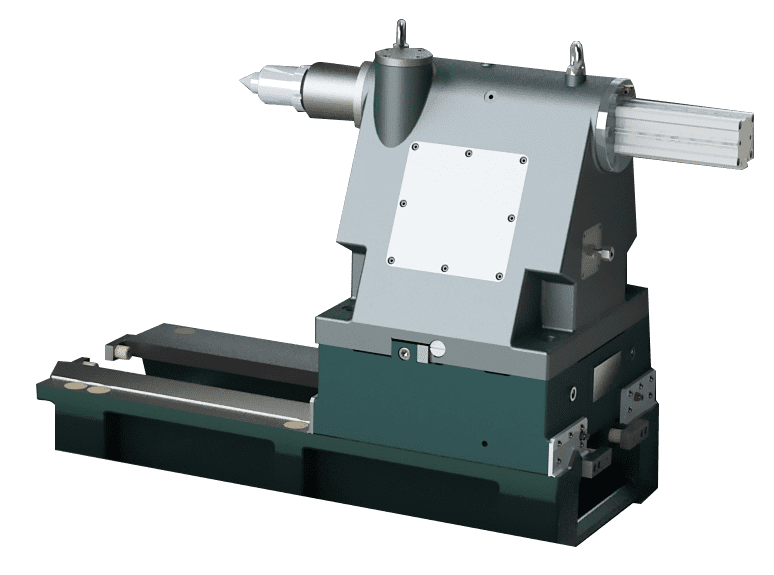

◇The upper and lower body of the tailstock adopts a compact structure design and is equipped with a hydraulic sleeve.

◇The tailstock adopts a sliding guide rail structure, and the strict scraping and grinding process ensures the contact rigidity of each joint surface.

3.Competitive Products Comparison

| ARTICOLO | UNITÀ | LH260-600 | Hardinge GS200 | |

|---|---|---|---|---|

| Capacità | Max. cutting diameter | mm | Φ360 | Φ356 |

| Max. cutting length | mm | 600 | 406 | |

| Mandrino | Spindle nose | A2-6 | A2-6 | |

| Max. bar diameter | mm | Φ52 | Φ52 | |

| Spindle speed | r/min | 50~4500 | 5000 | |

| Tool turret | Tool turret type | Horizontal hydraulic 8-station | Horizontal servo 12-station | |

| External diameter turning tool shank size | mm | 25 | 25 | |

| Internal diameter turning tool shank size | mm | 40 | 40 | |

| Precisione | X/Z axis positioning accuracy | mm | ≤0.005 | ≤0.005 |

| X/Z axis repeatable positioning accuracy | mm | ≤0.003 | ≤0.004 | |

| Dimensione | Machine height | mm | 1750 | 1781 |

| Occupied area | mmxmm | 2500X1690 | 1998X1551 | |

| Machine weight | kg | 4400 | 2794 |

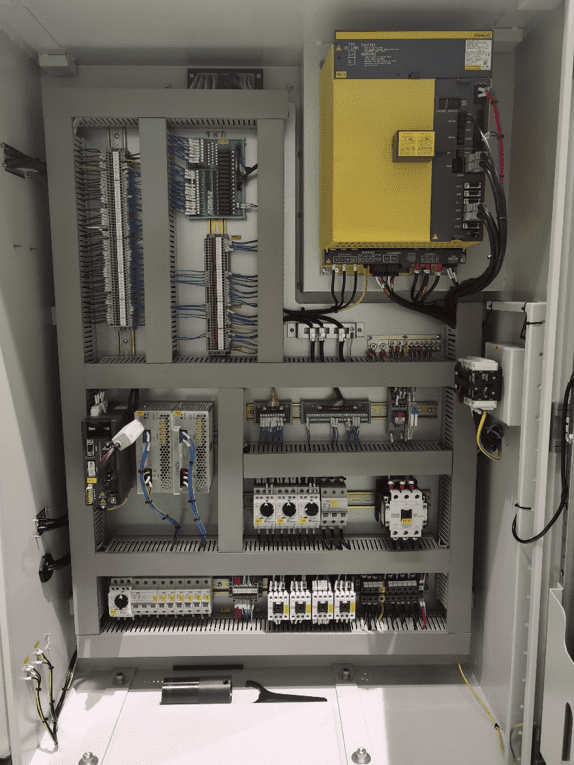

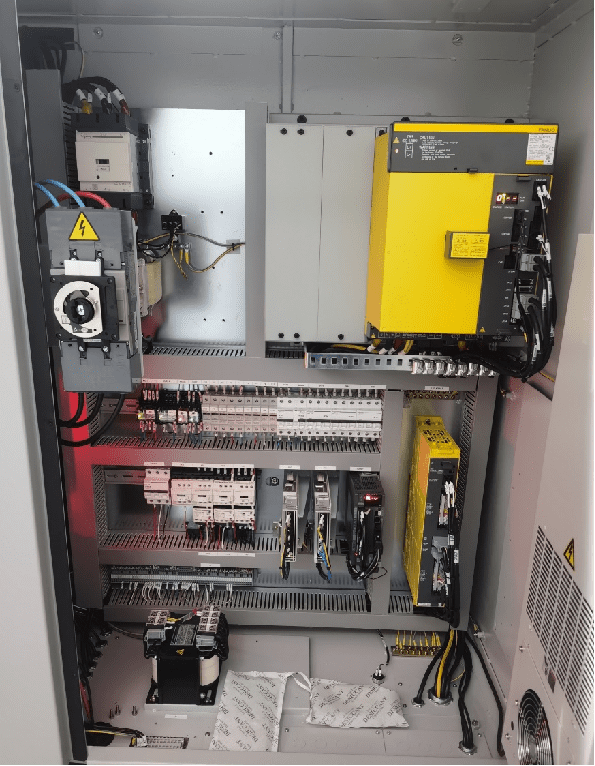

BORUI Electrical Cabinet

GS200 Electrical Cabinet

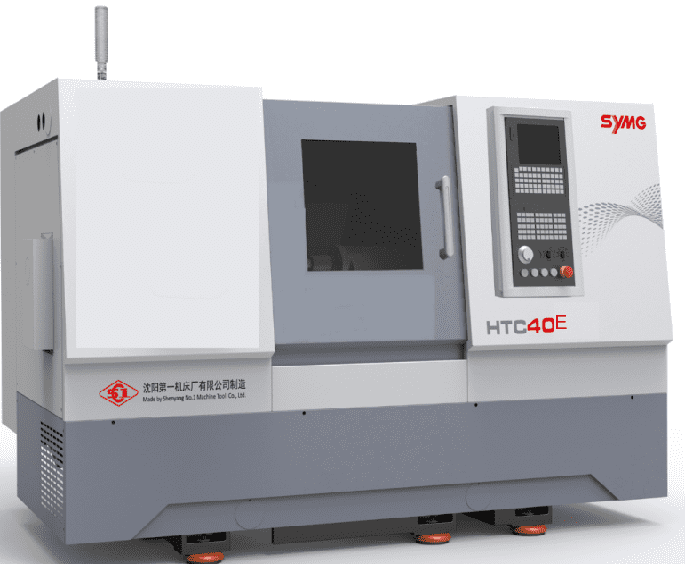

Compare To Domestic Products-First-Tier Domestic Brands

Max. machining length:600mm

Occupied area:2500mmX1690mm

Main machine weight:4400kg

Max. machining length:500mm

Occupied area:2700mmX1890mm

Main machine weight:3650kg

Larger processing range, heavier overall machine weight, smaller occupied area.

| ARTICOLO | UNITÀ | LH260-600(Borui) | HTC40E/500(Shenyang Machine) | |

|---|---|---|---|---|

| Capacità | Max. swing over the bed | mm | Φ520 | Φ500 |

| Max. cutting diameter | mm | Φ360 | Φ360 | |

| Max. cutting length | mm | 600 | 500 | |

| Mandrino | Spindle nose | A2-6 | A2-6 | |

| Spindle speed | r/min | 50~4500 | 50~4500 | |

| Spindle bearing bore | mm | Φ100 | Φ100 | |

| Tool turret | Tool turret type | Horizontal hydraulic 8-station | Horizontal hydraulic 8-station | |

| External diameter turning tool shank size | mm | 25 | 25 | |

| Internal diameter turning tool shank size | mm | 40 | 40 | |

| Alimentazione | Rapid feed rate | m/min | X:30 Z:30 | X:30 Z:30 |

| Contropunta | Tailstock taper hole type | Mohs | MT.5 | MT.5 |

| Tailstock travel | mm | 450(Sleeve travel100) | 450 | |

| Motore | Spindle motors | KW | 11kw/15kw | 11kw/15kw |

| Precisione | X/Z axis positioning accuracy | mm | 0.005 | 0.008 |

| X/Z axis repeatable positioning accuracy | mm | 0.003 | 0.004 | |

| Dimensione | Machine height | mm | 1750 | 1945 |

| Occupied area | mmxmm | 2500X1690 | 2700X1890 | |

| Machine weight | kg | 4400 | 3650 |

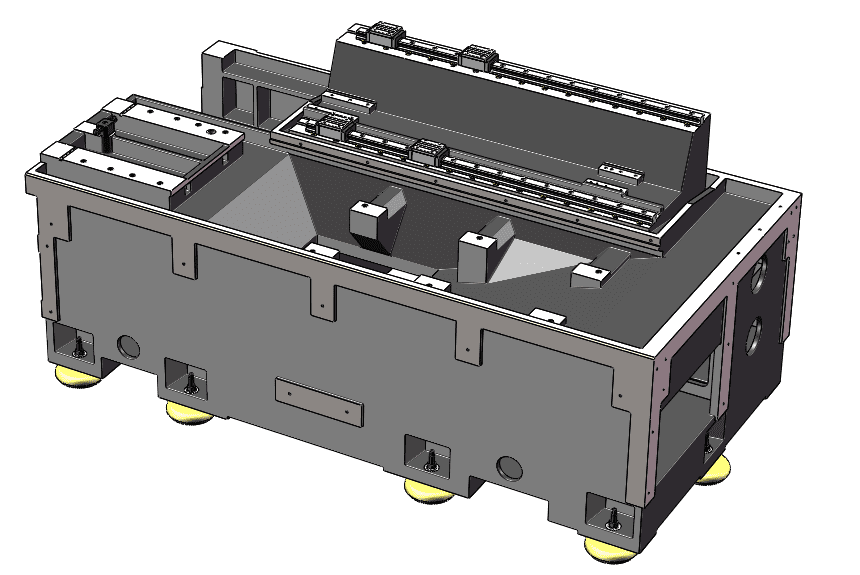

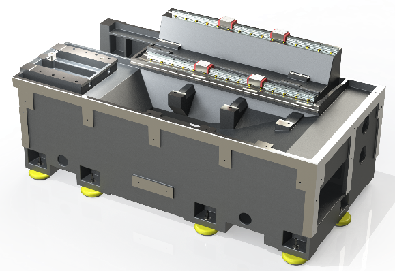

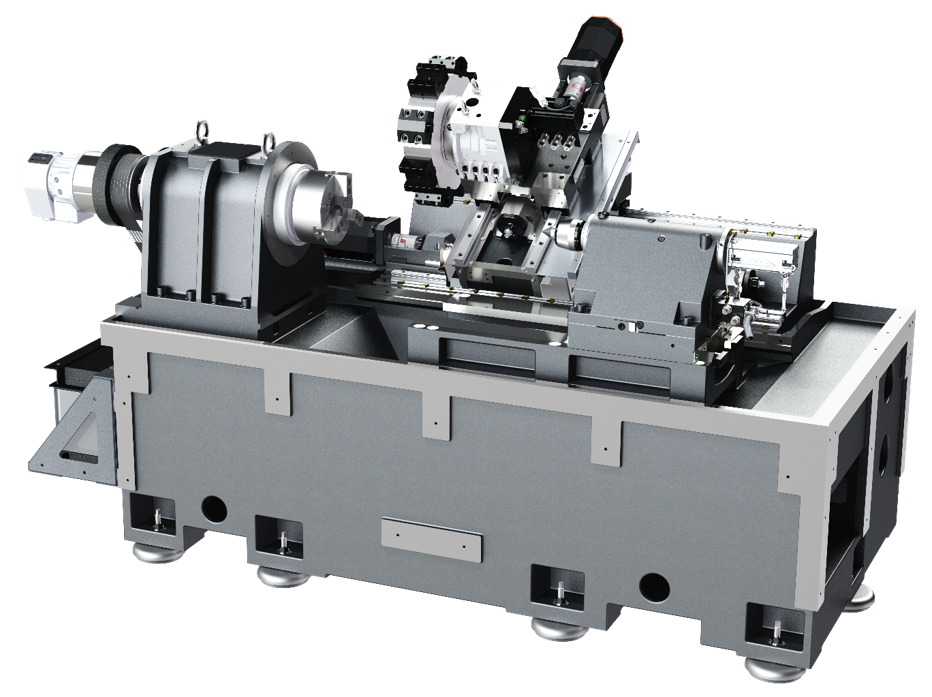

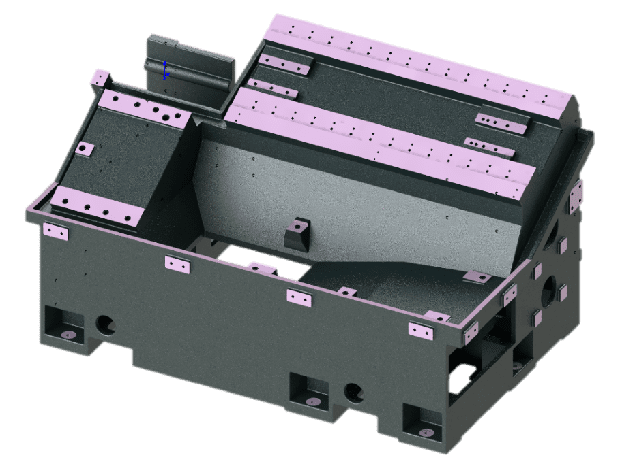

Integral slant bed with flat guide structure

Integral slant bed construction

Bed weight:2.4t

Support footing: 10

Leak-proof construction:Bed catching table

Oil and water separation:Include this, reduce cutting fluid contamination

Accuracy guarantee:Heat treatment process to reduce stress residues

Bed weight:1.6t

Support footing:8

Leak-proof construction:Splicing tables for sheet metal parts

Oil and water separation:Not include this, frequent cutting fluid changes required

Accuracy guarantee:No heat treatment process, slightly less stable accuracy

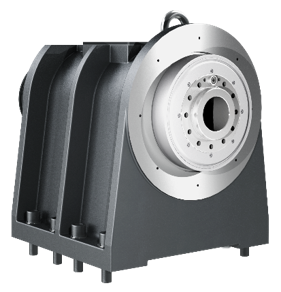

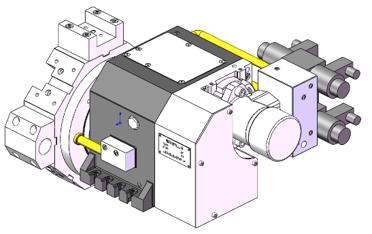

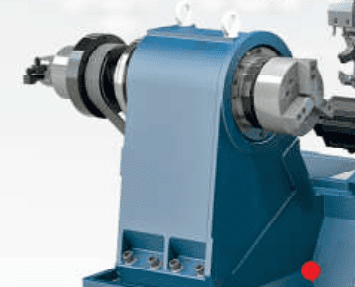

Symmetrical structure:Small temperature rise and thermal deformation, good stability of accuracy.

Scraping process: Flat push-to-grind for guaranteed contact rate with the bed.

Dynamic balancing grades:G0.4,Better vibration resistance.

Asymmetrical structures:High temperature rise and thermal deformation, slightly less stable accuracy.

Scraping process: Rotational counter-grinding, with no guaranteed contact rate with the bed.

Dynamic balancing grades:G1,Slightly less resistant to vibration.

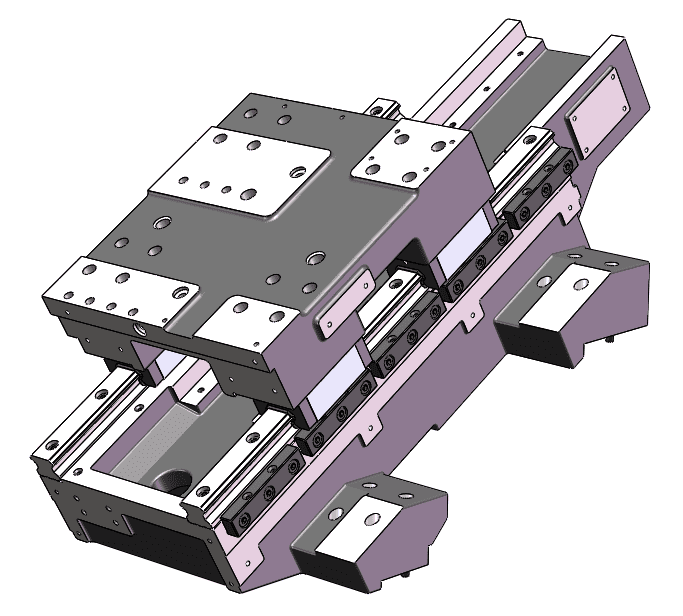

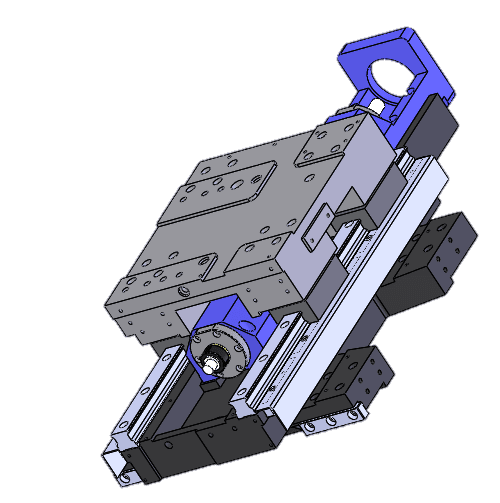

Bed saddle shape:Small triangular construction with thicker dimensions and more rigid .

Bed saddle shape:Parallel construction, thinner dimensions, slightly less rigid.

Small triangular bed saddle with superior load-bearing structure for greater rigidity.

Guide rail base:Increased thickness for greater rigidity. Tip height: Small distance between the tip and the guide for high rigidity.

Guide rail base:Thinner and slightly less rigid. Tip height: The distance between the tip and the guide is large and slightly less rigid.

More rational and rigid design, resulting in a significant increase in rigidity at the end of the table.