Il centro di lavoro è una sorta di efficiente macchina utensile CNC, insieme petrolio, gas, elettricità, controllo numerico come uno, può raggiungere una varietà di disco, piastra, shell, CAM, stampo e altre parti complesse del pezzo di serraggio, può completare la foratura, fresatura, alesatura, espansione, alesatura, maschiatura rigida e altri processi di elaborazione, quindi è l'ideale...

Archivio Categoria: CNC Machining Center

La raschiatura manuale delle macchine utensili è un metodo di lavorazione meccanica che consiste nel trattare la superficie metallica con un raschietto sulla macchina utensile, in modo da modificare la struttura e la lucentezza della superficie metallica. La raschiatura manuale delle macchine utensili è realizzata con attrezzature meccaniche e...

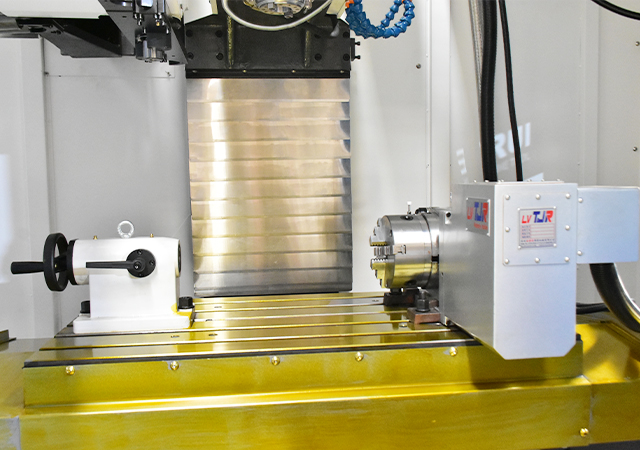

Il centro di lavoro a quattro assi è un'apparecchiatura di lavorazione ad alta precisione e ad alta efficienza in grado di muoversi e posizionarsi in tre direzioni (assi X, Y, Z) e di ruotare contemporaneamente, cioè il quarto asse. Il centro di lavoro a quattro assi è ampiamente utilizzato e può essere impiegato per lavorare vari materiali metallici e non metallici, come...

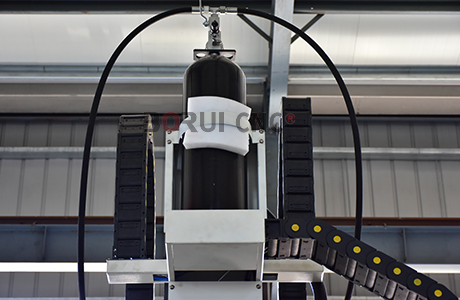

Il cilindro di bilanciamento dell'azoto per macchine utensili è un dispositivo utilizzato per bilanciare la pressione dell'azoto nelle macchine utensili. Di solito è costituito da un cilindro che contiene azoto gassoso e da un pistone che si muove all'interno del cilindro. Quando la macchina utensile ha bisogno di azoto, il pistone spinge verso l'esterno per immettere l'azoto nella macchina utensile; quando...

1. L'utensile utilizzato nel centro di lavoro è composto da un utensile universale (noto anche come testa di lavoro o testa dell'utensile) e da un'impugnatura che corrisponde al foro conico all'estremità anteriore del mandrino del centro di lavoro. Nell'applicazione, secondo...

Le prestazioni del sistema di controllo numerico determinano l'efficienza di lavorazione, la precisione di formatura e la stabilità di funzionamento delle macchine utensili a controllo numerico. Il sistema di controllo numerico può controllare la macchina utensile per realizzare lavorazioni a due, tre o più assi. La differenza tra il centro di lavoro e la normale macchina utensile CNC è...

Con l'applicazione del centro di lavoro a cinque assi in vari settori, aumenta anche l'argomento della lavorazione a cinque assi. Ad esempio, perché sempre più produttori tendono a utilizzare attrezzature a cinque assi per soddisfare l'alta qualità della lavorazione? Oggi diamo un'occhiata: Valore di esistenza di 5 assi: ...

Misurazione della precisione della vite di piombo: Poiché la precisione della vite di piombo è la principale precisione della macchina utensile, prima della revisione della macchina utensile è necessario controllare la precisione della vite di piombo per determinare le misure di riparazione della vite di piombo, o la riparazione, o la sostituzione. L'ispezione della vite...

L'accuratezza del cuscinetto sul mandrino della macchina utensile dovrebbe essere ISOP5 o superiore, mentre per il supporto del mandrino delle macchine utensili CNC, dei centri di lavoro e di altre macchine utensili ad alta velocità e ad alta precisione, dovrebbe essere selezionata l'accuratezza ISOP4 o superiore; i cuscinetti del mandrino includono i cuscinetti a sfere a contatto obliquo, i cuscinetti a rulli conici e i cuscinetti a rulli cilindrici....

Il centro di lavorazione Longmen è utilizzato principalmente nei settori aeronautico, aerospaziale, automobilistico, militare, dell'energia, dell'informazione, degli stampi e in altri settori di lavorazione delle parti. È progettato per lavorare parti complesse di grandi e medie dimensioni di metalli neri e non ferrosi. Ha le caratteristiche di alta precisione, alta velocità, alta flessibilità e protezione ambientale. I suoi indicatori di prestazione e...