Nel 2024, i 10 principali produttori di macchine CNC guideranno il settore con tecnologie innovative e prestazioni superiori. Questo elenco comprende marchi riconosciuti a livello mondiale, noti per i loro macchinari avanzati, l'affidabilità e l'efficienza in vari processi produttivi. Queste aziende sono all'avanguardia nell'ingegneria di precisione e offrono un'ampia gamma di macchine CNC per soddisfare le diverse esigenze industriali. L'articolo mette in evidenza i loro principali punti di forza, le offerte di prodotti e i contributi al panorama della lavorazione CNC, fornendo indicazioni preziose per le aziende che desiderano investire in attrezzature CNC di alta qualità.

Archivio Categoria: Uncategorized

La fresatura CNC è un processo di produzione sottrattiva che utilizza macchine controllate da computer per rimuovere il materiale da un blocco e creare parti precise e superfici piane. Il processo prevede il fissaggio del pezzo sulla macchina, dove gli utensili da taglio rotanti scolpiscono la forma desiderata spostando fisicamente il materiale.

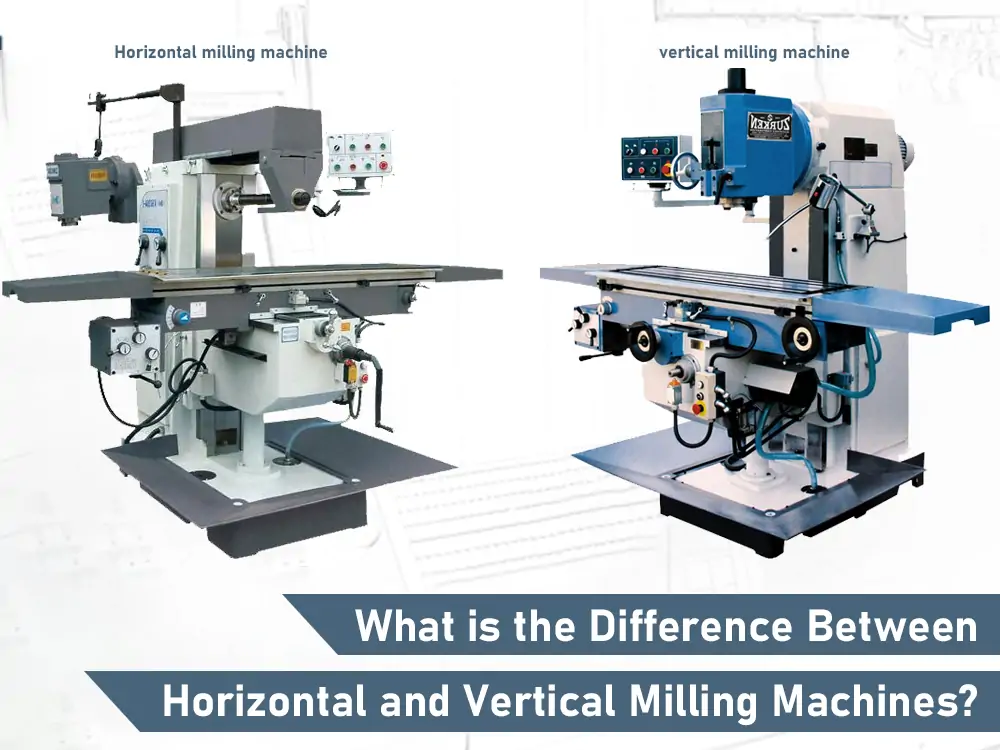

Le fresatrici sono strumenti essenziali nell'industria della lavorazione, utilizzati per modellare i materiali solidi. Esistono diverse fresatrici, ognuna con caratteristiche e applicazioni uniche. Alcuni tipi comuni sono le fresatrici verticali, le fresatrici orizzontali e le fresatrici a torretta. Conoscere i diversi tipi di fresatrici è fondamentale per scegliere lo strumento giusto per il lavoro.

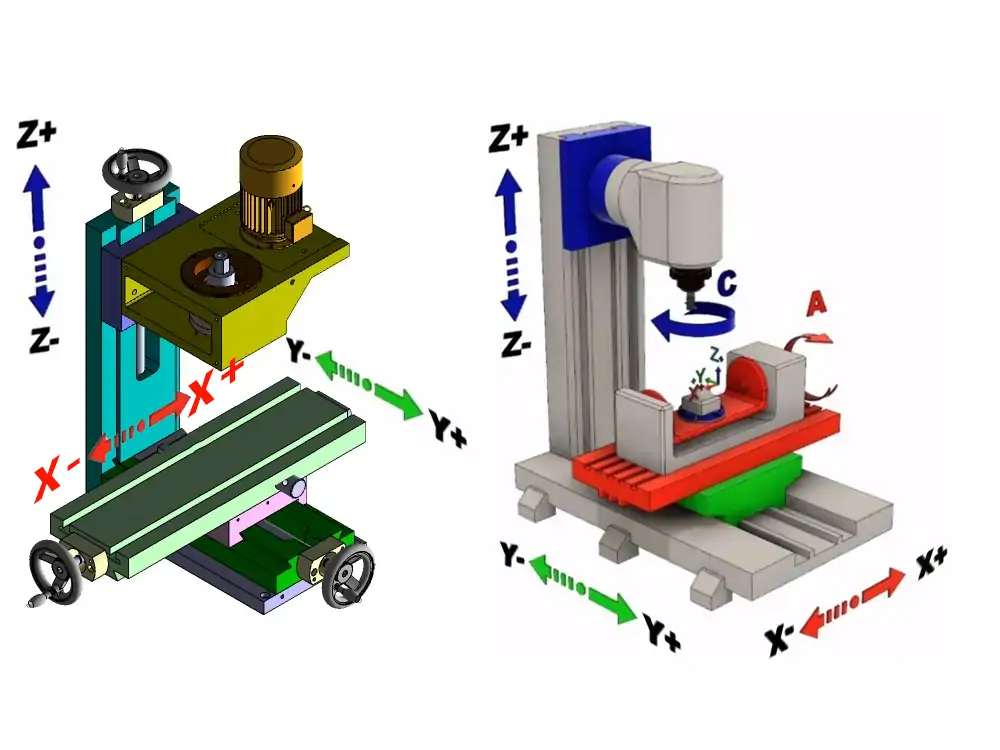

Le macchine a 3 assi sono adatte per pezzi semplici e operazioni di fresatura standard. Si tratta di una soluzione semplice ed economica. Le macchine a 5 assi offrono una versatilità avanzata, consentendo di produrre geometrie complesse e pezzi di alta precisione con un minor numero di impostazioni.

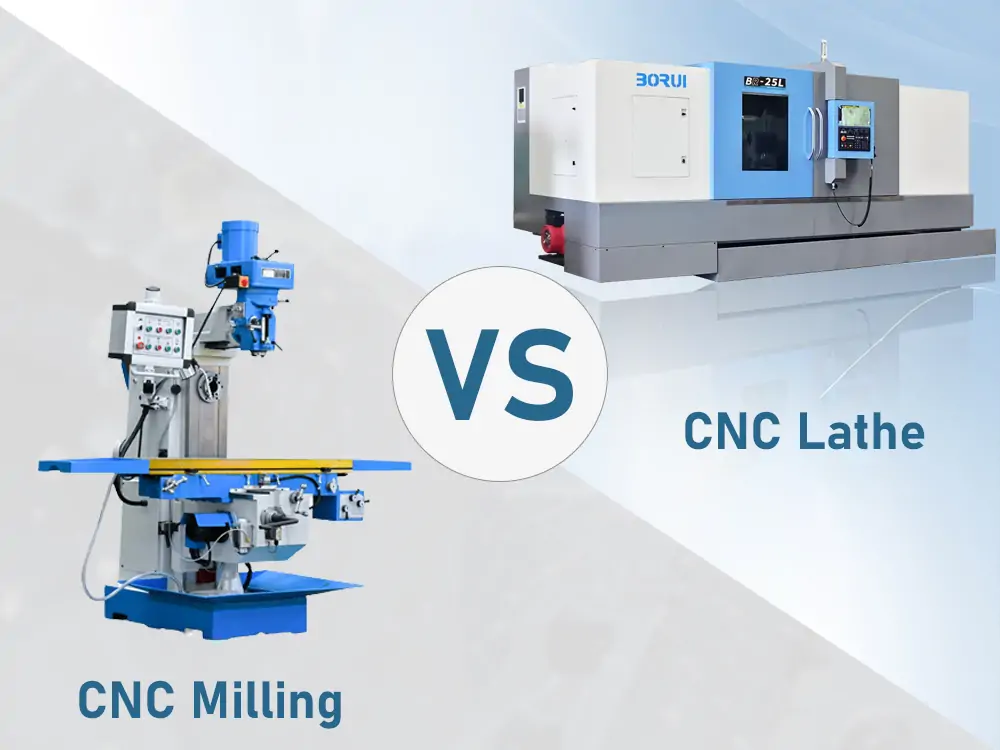

Il tornio e la fresa CNC sono macchine standard utilizzate nella lavorazione dei metalli. Il loro utilizzo è simile, in quanto servono a tagliare e modellare qualsiasi materiale. Tuttavia, funzionano in modo diverso. Le differenze tra tornio CNC e fresatura CNC sono molto evidenti. Entrambi questi strumenti si differenziano per il modo in cui lavorano e operano. Una fresatrice CNC...

Volete acquistare centri di lavoro orizzontali CNC? O siete interessati ad essi ora? Quando si sceglie un centro di lavoro orizzontale CNC, si deve prendere in considerazione la scelta di un produttore adatto. I migliori produttori di centri di lavoro orizzontali CNC svolgono un ruolo fondamentale nella produzione. Possono fornire parti e componenti critici a varie industrie in tutto il mondo....

Nella fabbricazione dei metalli, la fresatura è il metodo più diffuso per rimuovere componenti specifici dal materiale. In questa tecnica, un pezzo bloccato sul tavolo viene tagliato con un utensile da taglio che ruota rapidamente. L'utensile può tagliare il materiale in qualsiasi forma e dimensione desiderata. È possibile allineare una fresatrice...

Esistono molti tipi diversi di seghe a nastro che si possono utilizzare per tagliare e realizzare oggetti. Ogni tipo di sega a nastro è in grado di gestire una serie di compiti diversi. Assicurarsi di utilizzare la sega a nastro adatta per il lavoro da svolgere migliorerà la sicurezza, velocizzerà il lavoro e produrrà un taglio migliore. Potreste...

Un tornio CNC piano è utilizzato principalmente per la tornitura di carichi pesanti e può realizzare dischi, alberi corti e forme complesse. Può anche realizzare diverse filettature interne ed esterne con valori metrici o imperiali. Una volta posizionata sulla macchina CNC a tavola piana, la testa rotante può fresare o forare il bordo del pezzo e il suo contorno. La...

Dal magazzino utensili si può capire se una macchina a controllo numerico computerizzato (CNC) è un centro di lavoro CNC o un centro di fresatura CNC. Un tornio a controllo numerico computerizzato è una macchina automatizzata dotata di un metodo di controllo dei programmi. Quando il sistema di controllo legge il programma, può utilizzare codici di controllo o...