In the field of modern industry, with the continuous progress of science and technology, CNC machining has gradually replaced the traditional machining to become the mainstream. Compared with traditional machining, CNC machining not only has significant differences in technology, but also has obvious advantages in efficiency, precision and flexibility.

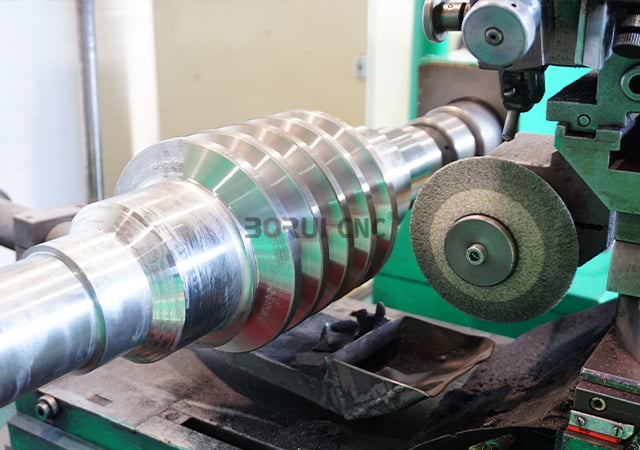

CNC machining technology originated from conventional machining technology, is the organic combination of conventional machining technology, computer numerical control technology, computer aided design and aided manufacturing technology. Due to the continuous development of technology, modern manufacturing needs more and more precision machined parts, processing accuracy and the complexity of the workpiece surface requirements are also getting higher and higher.

Efficienza della produzione

Production efficiency CNC machining uses computer programs to control machine tools for processing, while traditional processing relies on manual operation by workers. This enables CNC machining to have a higher degree of automation and production efficiency.

Stabilità

CNC machining has higher machining accuracy and stability. CNC machine tools can achieve high-precision machining, avoiding the error caused by the inaccurate operation of workers in traditional machining. In addition, CNC machining can also monitor the processing process in real time through the automated detection system, and adjust the parameters of the machine tool in time to ensure the consistency and stability of the product.

Flessibilità

CNC machining has higher flexibility and adaptability. Traditional machining usually requires the production of special fixtures and molds to complete specific processing tasks, while CNC machining can adapt to different processing needs by modifying the program, without re-manufacturing fixtures and molds. This not only saves time and costs, but also improves the flexibility and adaptability of production.

Techniques Of Handling

In ordinary machine tool processing technology, no matter the positioning reference, clamping method, tool, cutting method, etc., can be simplified, but the data processing technology is more complex, and these factors need to be fully considered, and even if it is the same processing task, CNC machining technology can also have multiple procedures.

Clamping Fixture

In CNC machining technology, it is not only necessary to fix the coordinate direction of the fixture and the machine tool, but also to coordinate the dimension relationship between the parts and the machine coordinate system. And the two steps of positioning and clamping need to be effectively controlled in the clamping process. Under the traditional processing technology, due to the limited processing capacity of the machine tool itself, it is necessary to carry out multiple clamping during the processing. The need to use a special fixture, which leads to a higher cost in the design and manufacturing of the fixture, which virtually increases the production cost of the product. And CNC machining process positioning can be used to debug the instrument, in most cases do not need to carry out special fixture design, so relatively speaking, its cost is relatively low.

Tool

In the processing process, it is necessary to determine the choice of tools according to different processing technologies and processing methods. At present, there is also a dry cutting method, which does not add cutting fluid or only adds a small amount of cutting fluid when cutting, so the tool needs to have good heat resistance. Compared with ordinary machining technology, NC machining technology has higher requirements for tool performance.

CNC machining, with its high degree of automation, precise machining and flexible production mode, has become an indispensable and important process in modern industry. With the continuous development of science and technology, CNC machining will continue to promote the progress and development of industry.

https://www.youtube.com/watch?v=sFFE7p2qNAQ

Richiesta di offerta