1. Which brand of 5-axis machining center is good?

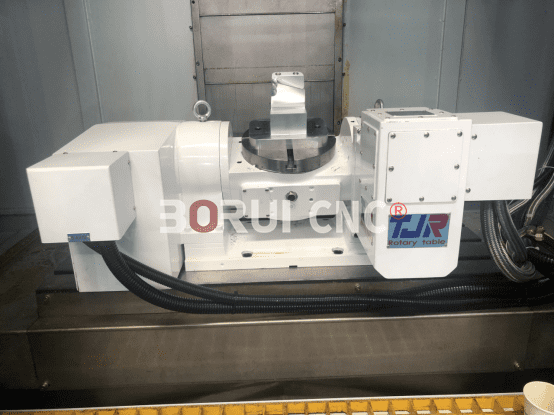

There are many brands of five-axis machining centers. Different brands of five-axis machining centers have different positioning and have different prices. Some brands are positioned in the high-end market, such as Germany’s Demagie, Hammer, Switzerland’s Baume, Weiliming, Japan. Some international first-line brands such as Mazak and Brother, which have high positioning and high prices, are suitable for customers with abundant funds and high requirements. Some brands are positioned as cost-effective, such as Taiwan TJR, Dongtai and other Taiwanese brands of five-axis machining centers are known for their high cost performance. Most domestic brands of five-axis machining centers are economical, and each has its own unique advantages. It is hard to say which one is better and which one is not. It can only be selected according to customer needs. Buying a five-axis machining center should be Buy the best brand, not the best brand.

https://www.youtube.com/watch?v=YLWXQe_GK_0

Learn more about 5-axis machining centers.

2.The characteristics of 5-axis machining center

The five-axis machining center has the characteristics of high efficiency and high precision, and complex machining can be completed in one clamping. The five-axis machining center is based on the three-axis machining center and is equipped with two more rotation axes around two of the three axes of XYZ. It involves a wide range of processing, and has a pivotal influence in aviation, military, scientific research, precision machinery, high-precision medical equipment and other industries. It is generally used for the processing of complex spatial surfaces, such as propellers, impellers, heavy generator rotors, steam turbine rotors, etc. These complex parts are almost the only way to process them with a five-axis machining center.

4 Axis CNC Vertical Machining Center VS 5Axis CNC Vertical Machining Center:

1. What is the difference between a 4-axis machining center and a 5-axis machining center?

Ordinary machining centers have only X, Y, Z, and 3 axes. The machining center that adds one more rotary axis to the XYZ axis is called a four-axis machining center, and the machining center that adds two rotary axes is called a five-axis machining center.

The 4-axis machining center has three different additional rotation axes, namely A, B, and C. The A axis is the axis that rotates around the X axis, and so on, the B axis corresponds to the Y axis, and the C axis corresponds to the Z axis. The three rotating axes of ABC are also called indexing heads. The four-axis machining center is a three-axis machining center that adds an indexing head. The specific coordinate axis added depends on the customer’s needs.

The 5-axis machining center is somewhat similar to the 4-axis machining center, but it is not exactly the same. The 5-axis machining center also adds indexing heads, but two are also added, and they can only be added during the installation process, which means that it cannot be directly added to the X, Y, and Z axes on a complete 3-axis machining center. . Similar to the 4-axis machining center, the 5-axis machining center just selects two of the ABC3 rotating axes, which can be AB, AC, BC. It is precisely because the 5-axis machining center has one more rotation axis than the 4-axis machining center, so the workpiece that can be machined by the 5-axis machining center may not be machined by the 4-axis machining center, while the workpiece that can be machined by the 4-axis machining center can be machined by the 5-axis machining center. processing.

The 4-axis machining center can process some simple curved surfaces through the linkage of a rotary axis with X, Y, Z, and 3 linear axes, while the 5-axis machining center has one more indexing head than the 4-axis machining center, so it can be processed through two The rotation axis and X, Y, Z, 3 linear axes realize linkage to process more complex spatial surfaces.

https://www.youtube.com/watch?v=QQfPU97mEJM

Learn more about 4-axis machining centers.

2. What is the difference between 4-axis machining center and 5-axis machining center programming?

In terms of programming, the programming of the 4-axis machining center is quite different from the programming of the 5-axis machining center. When the 4-axis machining center processes the workpiece, the tool axis is always towards the axis of rotation of the workpiece. Machining centers are relatively similar. When a 5-axis machining center processes a workpiece, since the tool and the workpiece are adjusted at any time during the machining process, for example, when machining a propeller, in order to obtain a better surface quality, the angle between the tool and the blade surface must always be consistent, that is It is said that the direction of the tool axis is constantly changing, and manual interpolation of the tool axis is often required. When processing these complex spatial surfaces, there are many more parameters to be considered than when programming a 4-axis machining center, and there are higher requirements for the CNC system. If you use a general CNC system, it will increase the difficulty of programming and affect the accuracy of the machine tool. Most 5-axis machining centers use Mitsubishi or Fanuc CNC systems, while 4-axis machining centers do not have such high requirements.