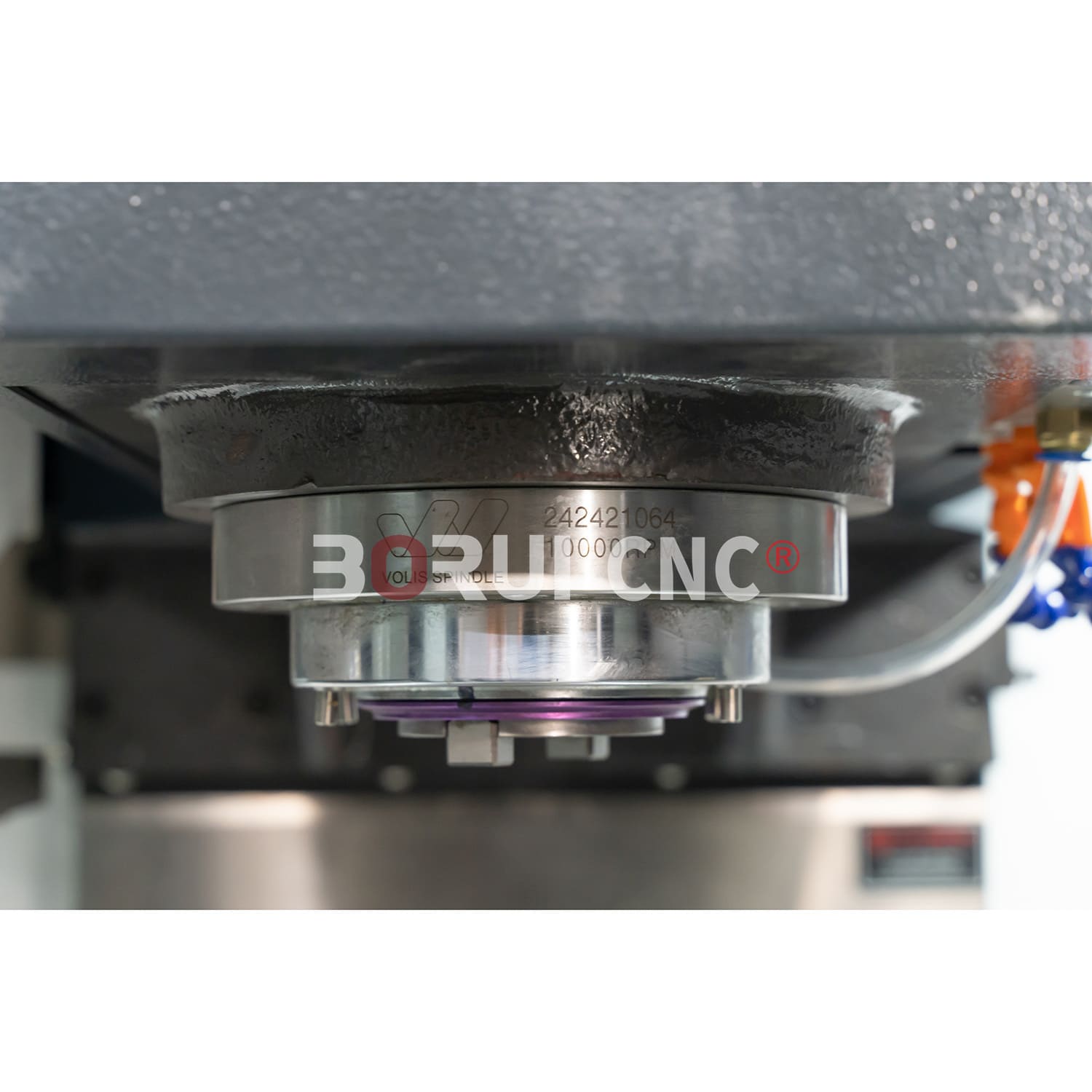

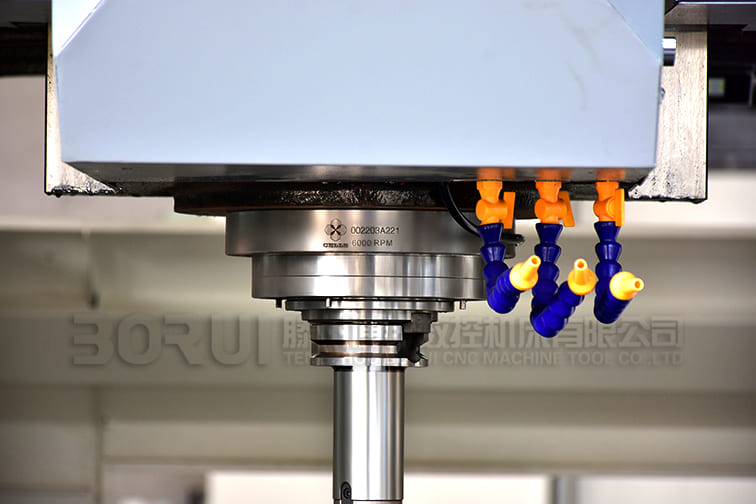

Spindle components:

It is the main component that affects the machining accuracy of the machining center

Rotation accuracy affects the machining accuracy of the workpiece

Power and rotation speed affect processing efficiency

Automatic shifts, exact stops and tool changes that affect the automation of the machine tool

Common faults of machining center spindle

Machining accuracy does not meet the requirements:

1. The machine tool is impacted during transportation

2. The installation is not firm, the installation accuracy is low or there are changes

Large cutting vibration:

1. The screws connecting the headstock and the bed are loose

2. Insufficient bearing preload and excessive clearance

3. The bearing preload nut is loose, causing the main shaft to move

4. Bearings are brushed or damaged

5. The spindle and the box are out of tolerance

6. Other factors

7. If it is a lathe, it may be that the moving parts of the turret tool rest are loose or the pressure is not enough and not clamped

The noise of the headstock is large:

1. The dynamic balance of the spindle components is not good

2. The gear meshing clearance is uneven or seriously damaged

3. The bearing is damaged or the drive shaft is bent

4. The length of the transmission belt is different or too loose

5. Poor gear accuracy

6. Poor lubrication

Gear and bearing damage:

1. The shifting pressure is too large, and the gear is damaged due to impact

2. The gear shifting mechanism is damaged or the fixing pin falls off

3. Bearing preload is too large or no lubrication

The spindle has no speed change:

1. Whether the electrical shift signal is output

2. Is the pressure enough?

3. The gear shifting hydraulic cylinder is worn or stuck

4. The shift solenoid valve is stuck

5. The shifting fork of the shifting hydraulic cylinder falls off

6. Oil channeling or internal leakage of gear shifting hydraulic cylinder

7. The shift compound switch fails

The spindle does not rotate:

1. Whether the spindle rotation command is output

2. The protection switch is not pressed or failed

3. The chuck does not clamp the workpiece

4. The composite switch of shifting gear is damaged

5. Leakage in the shift solenoid valve body

The spindle heats up:

1. The preload of the main shaft bearing is too large

2. Bearing scratches or damage

3. The lubricating oil is dirty or has impurities

The gear is not pushed in place during hydraulic shifting:

1. The fork in the headstock is worn