장비 기술 설명:

TCK56 CNC 선반은 자동차, 항공우주, 금형, 계측기 등 다양한 산업에서 중소형 부품의 고효율 가공 요구를 폭넓게 충족할 수 있는 고강성, 비용 효율적인 공작 기계입니다.

전체: 기계 및 전기 통합 설계, 컴팩트한 구조, 합리적인 레이아웃, 아름다운 외관, 45° 경사 베드, 직사각형 플라스틱 코팅 가이드 레일, 완전 밀폐형 보호 장치, 자동 오른쪽 칩 제거, 유압 척, 유압 심압대, 3색 조명, 자동 윤활 시스템.

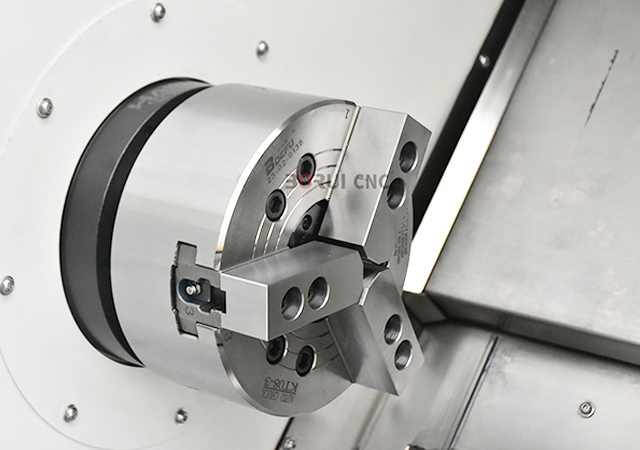

척: 3조 척 표준, 4조 척 옵션, 공작물 클램핑 고정, 고강성 주철로 긴 사용 수명을 제공합니다.

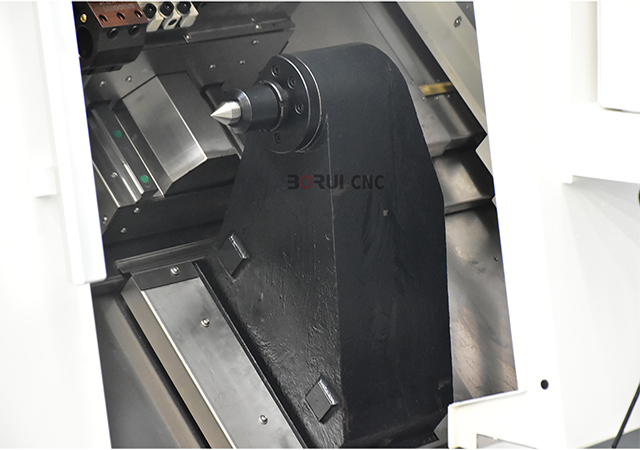

심압대: 고정밀, 고강성, 안정적인 성능을 갖춘 슬리브형 유압 심압대.

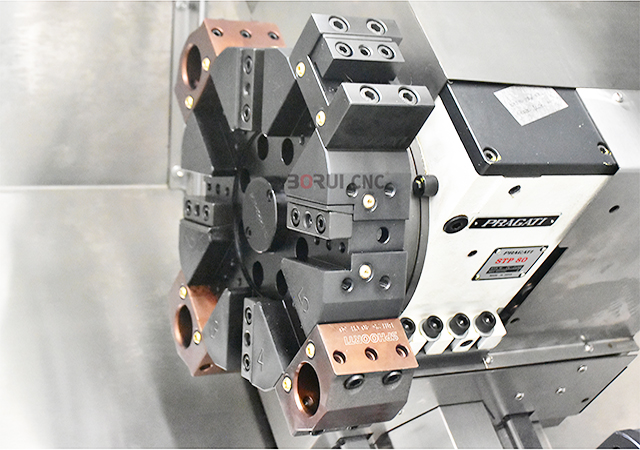

터렛: 빠른 공구 교환 속도와 높은 신뢰성을 갖춘 고신뢰성 유압식 공구 포스트를 채택했습니다.

드라이브: 종 방향 및 수평 드라이브는 고성능 서보 모터와 볼 스크류를 채택하고 공작 기계의 위치 결정 정확도와 반복 위치 결정 정확도가 높습니다. 고강성 가이드 레일을 사용하여 모션 정밀도와 동적 특성이 우수합니다.

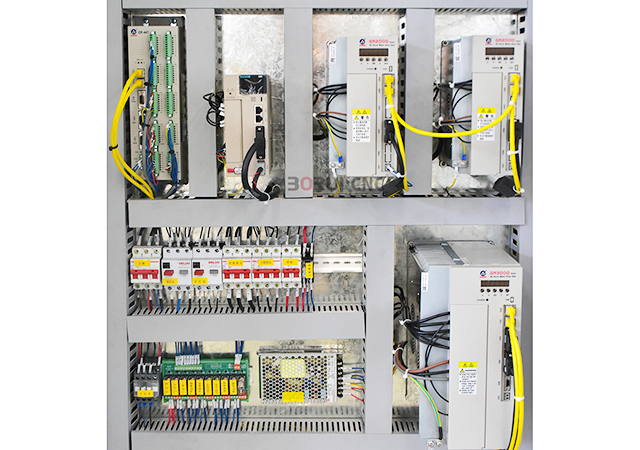

시스템: 안정적인 성능으로 GSK 수치 제어 시스템과 AC 수직 및 수평 서보 시스템을 채택합니다. 고성능 서보 메인 모터, 고 토크 및 고출력을 채택하여 일정한 선형 속도 절단을 실현할 수 있습니다.

공작 기계 가공 및 조립의 모든 부품과 구성 요소의 품질은 제품 도면 및 관련 기술 요구 사항을 충족합니다.

장비 특성:

TCK56 경사 베드 CNC 선반의 단면적은 동일한 사양의 평평한 베드보다 크며, 즉 굽힘 및 비틀림 저항이 더 강합니다. 경사 베드 CNC 선반의 공구는 공작물의 비스듬한 상단에서 아래쪽으로 절단되며 절삭력은 기본적으로 공작물의 중력 방향과 일치하므로 스핀들이 비교적 부드럽게 작동하여 절삭 진동을 일으키기 쉽지 않습니다. 평판 CNC 선반이 절단 할 때 공구와 공작물에 의해 생성되는 절삭력은 공작물의 중력에 대해 90 °이므로 진동을 일으키기 쉽습니다. 다음으로 가공 정확도를 비교합니다. CNC 선반의 변속기 나사는 고정밀 볼 스크류입니다. 나사와 너트 사이의 전송 간격은 매우 작지만 간격이 없다는 의미는 아닙니다. 간격이있는 한 나사가 한 방향으로 움직이면 반전됩니다. 백래시가 있으면 백래시가있을 수밖에 없으며 백래시는 CNC 선반의 반복 위치 결정 정확도에 영향을 미치므로 가공 정확도에 영향을 미칩니다.

경사 베드 CNC 선반은 고정밀, 고효율 자동 공작 기계입니다. 선형 롤링 가이드는 고속 및 고효율 요구 사항을 충족하고 마찰 저항과 온도 상승 변형을 줄이며 가공 정확도를 개선하고 절삭 가공 정확도의 장기적인 안정성을 보장 할 수 있습니다. 공구 감지 장치는 공구 팁의 위치 데이터를 수치 제어 시스템에 자동으로 입력하여 공구 교체시 정착 시간을 크게 단축하고 공구 팁의 마모를 자동으로 보정 할 수도 있습니다. 경사 베드 CNC 선반은 국내 또는 수입 고 강성 수평 터렛 공구 포스트를 채택하여 위치 정확도가 높고 무거운 절단시 변형이 적습니다. 표준 스핀들 무단 속도 조절, 유압 척, 유압 심압대, 수평 8 스테이션 공구 포스트, 폐쇄 보호. 전체 경사 베드 구조를 채택하여 무거운 절삭 중에도 공작 기계 정밀도의 안정성을 유지할 수 있습니다.

https://www.youtube.com/watch?v=LqBdGrSLTiw

견적 요청