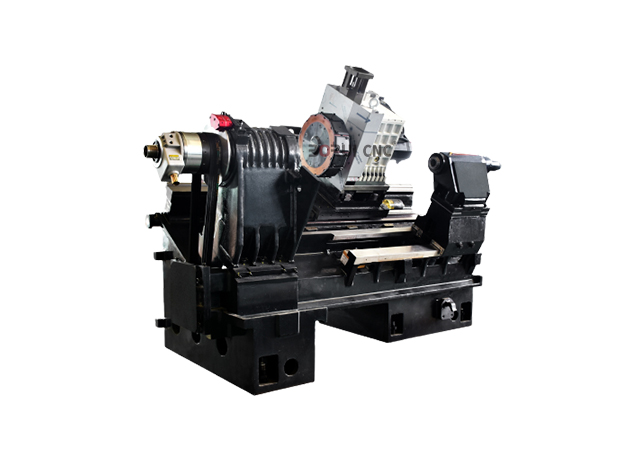

경사 베드가있는 CNC 선반은 고정밀 및 고효율의 자동 공작 기계의 일종입니다. 멀티 스테이션 타워 또는 파워 타워가 장착 된 공작 기계는 광범위한 가공 성능을 가지고 있으며, 경사 베드 CNC 선반은 현대 기계 장비로서 많은 독특한 구조적 특성을 가지고 있습니다. 독특한 디자인으로 ...

드릴링 홀 드릴링은 드릴링 도구를 사용하여 구멍을 뚫는 과정을 말합니다. 엔지니어링 및 건설 분야에서 드릴링은 파이프, 전선, 볼트 등을 설치하기 위해 구멍을 뚫는 데 사용되는 일반적인 작업입니다. 드릴링은 원하는 구멍 크기와 지질학적 특성에 따라 회전, 타악기 또는 진동으로 수행할 수 있습니다.

머시닝 센터는 현대 산업 생산에서 없어서는 안 될 중요한 장비이며, 그 정확도는 제품의 품질과 성능에 결정적인 영향을 미칩니다. 정확도는 가공 공정에서 머시닝 센터의 크기, 모양 및 위치 정확도를 의미하며, 이는 정확도, 안정성 및 ...와 직접적으로 관련이 있습니다.

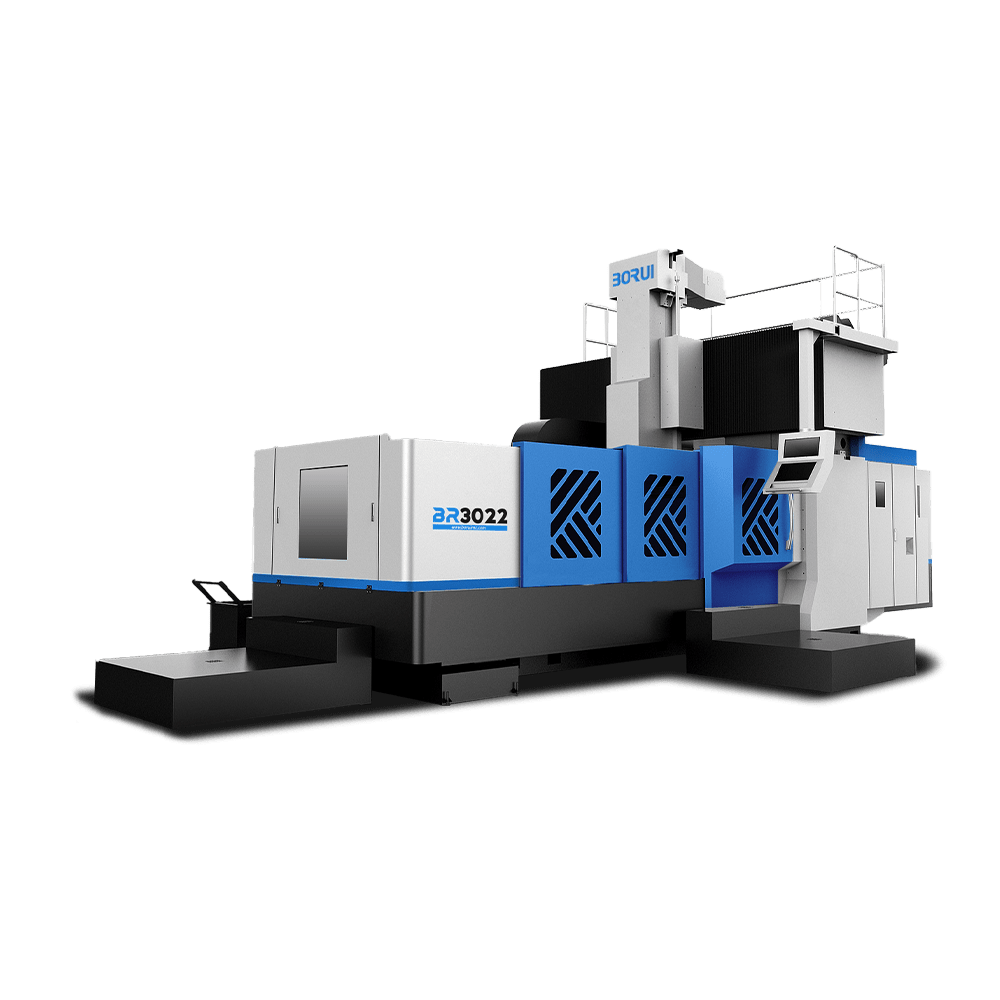

갠트리 밀링 머신은 일반적인 금속 가공 장비이며 구조적 특성이 독특하고 실용적입니다. 아래에서는 갠트리 밀링 머신의 구조적 특성을 자세히 소개합니다. 1. 구조는 주로 다음 부품을 포함합니다: 침대 : 침대는 갠트리 밀링 머신의 주요 부분이며 일반적으로 다음으로 만들어집니다.

드릴링의 중요성은 사회 발전을 주도합니다. 제조 산업에서 중요한 역할을 하며 다양한 산업에 필수적인 부품과 공정을 제공합니다. 공작 기계 드릴링 기술의 적용으로 우리는 현대 생활과 편리함을 누릴 수 있습니다. 공작 기계 드릴링 공정은 다음과 같은 과정을 거쳐야 합니다.

CNC 선반은 고정밀, 고효율의 가공 장비의 일종으로 많은 분야에서 널리 사용되고 있습니다. 다음으로 CNC 선반의 응용 분야를 소개하겠습니다. 우선 CNC 선반은 항공 우주 분야에서 중요한 역할을합니다. 항공 우주 분야는 정확성, 품질에 대한 요구 사항이 매우 높습니다 ...

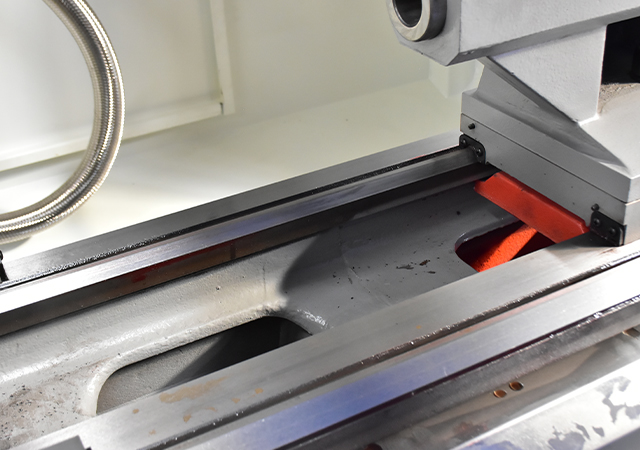

CNC 공작 기계 선형 축의 위치 감지 요소 인 격자 눈금자는 인간의 "눈"과 동일하며, 이는 CNC 시스템의 이동 지침 실행 후 선형 축이 실제로 CNC 시스템 지침에 필요한 위치로 정확하게 실행되는지 여부에 관계없이 선형 축을 "모니터링"하는 것입니다.....

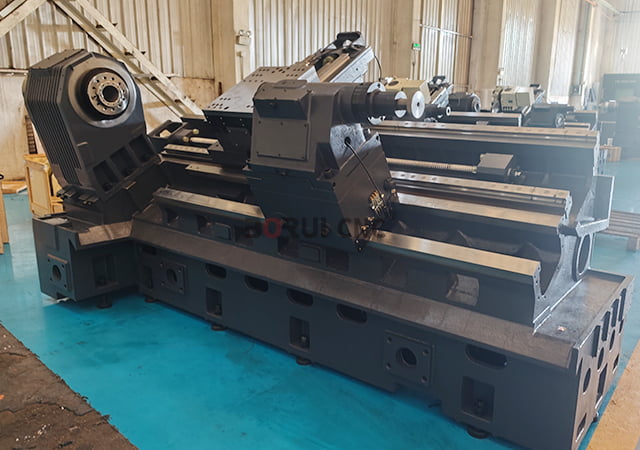

대구경 CNC 선반은 일종의 고정밀 고효율 공작 기계로 현대 산업 생산에서 중요한 역할을하며 모든 계층의 발전에 강력한 지원을 제공합니다. 그것은 산업 생산에서 광범위한 응용 분야를 가지고 있으며 모든 계층의 요구를 충족시킬 수 있습니다 ...

새로운 가이드 시스템을 통해 기계는 동일한 스핀들 속도에서 리니어 가이드의 특성인 빠른 이송 속도를 달성할 수 있습니다. 리니어 가이드와 평면 가이드에는 두 가지 기본 구성 요소가 있습니다. 하나는 가이드 역할을 하는 고정 요소이고 다른 하나는 움직이는 요소입니다. In...

전자 기술, 자동 정보 처리, 데이터 처리 및 전자 컴퓨터의 출현으로 자동화 기술은 디지털 신호를 사용하여 CNC 선반 경사 베드의 동작 및 가공 프로세스를 제어하고 공작 기계 자동화의 발전을 촉진하는 새로운 개념을 가져 왔습니다. 일종의 높은 CNC 선반 ...