수직형 CNC 선반은 기존의 수평형 선반에 비해 많은 장점을 제공하는 강력한 기계입니다. 이 기계는 다양한 가공 응용 분야에 이상적인 몇 가지 고유한 기능을 제공하기 때문에 최근 몇 년 동안 점점 더 인기를 얻고 있습니다. 이 기사에서는 수직형 CNC의 주요 장점 몇 가지를 살펴봅니다...

CNC 경사 베드 선반은 정밀 가공을 위한 일종의 컴퓨터 수치 제어(CNC) 공작 기계입니다. 금속, 목재 및 플라스틱과 같은 재료를 높은 정밀도와 반복성으로 절단하고 성형하도록 설계되었습니다. 이 백서에서는 CNC 경사 베드 선반의 구조, 장점 및 응용 분야를 이해합니다 ...

톱 기계는 산업 가공에서 중요한 역할을하며, 아침 조각 기계는 주로 밴드 톱 기계와 원형 톱 기계를 생산합니다. 제조업체는 도매 주문을 원하지만 선택 방법을 모릅니다. 아래에서 Xiaobian이 원형 톱 기계와 밴드 톱 기계의 차이점에 대해 알려 드리겠습니다. A...

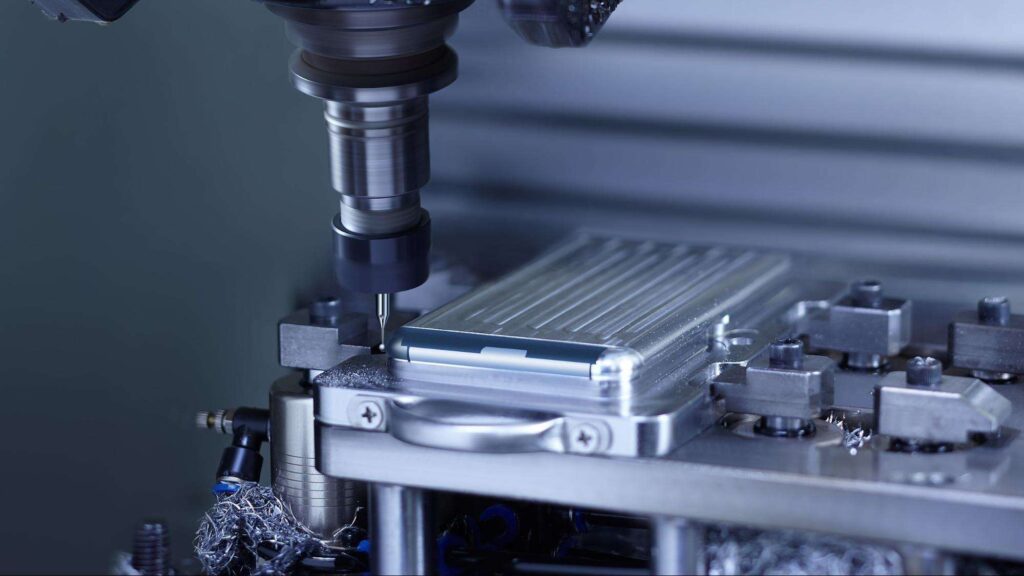

1. 머시닝 센터 도구란 무엇입니까 : 머시닝 센터에서 사용되는 도구는 범용 도구 (작업 헤드 또는 도구 헤드라고도 함)와 머시닝 센터 스핀들 앞쪽 끝의 테이퍼 구멍과 일치하는 도구 핸들로 구성됩니다. 응용 프로그램에서 ...

수치 제어 시스템의 성능에 따라 수치 제어 공작 기계의 가공 효율, 성형 정확도 및 작동 안정성이 결정됩니다. 수치 제어 시스템은 공작 기계를 제어하여 2축, 3축 또는 다축 연계 가공을 달성할 수 있습니다. 머시닝 센터와 일반 CNC 공작 기계의 차이점은 ...

다양한 분야에서 5 축 머시닝 센터가 점점 더 많이 적용됨에 따라 5 축 가공에 대한 주제도 증가하고 있습니다. 그렇다면 점점 더 많은 제조업체가 고품질 가공을 위해 5축 장비를 사용하는 이유는 무엇일까요? 오늘은 그 이유를 살펴보겠습니다: 5축의 존재 가치: ...

리드 스크류 정확도 측정: 리드 스크류 정확도를 공작 기계의 주요 정밀도로 사용하여 공작 기계를 정밀 검사하기 전에 리드 스크류의 수리 조치를 결정하거나 수리 또는 교체하기 위해 리드 스크류의 정밀도를 확인해야합니다. 리드 검사 ...

공작 기계의 스핀들에 대한 베어링 정확도는 ISOP5 이상이어야하며 CNC 공작 기계, 머시닝 센터 및 기타 고속 및 고정밀 공작 기계의 스핀들 지원을 위해 ISOP4 이상의 정확도를 선택해야합니다. 스핀들 베어링에는 앵귤러 콘택트 볼 베어링, 테이퍼 롤러 베어링 및 원통형 롤러 베어링이 포함됩니다.....

롱먼 가공 센터는 주로 항공, 항공 우주, 자동차, 군사, 에너지, 정보, 금형 및 기타 부품 가공 산업에서 사용됩니다. 흑색 및 비철금속의 대형 및 중형 복합 부품을 처리하도록 설계되었습니다. 고정밀, 고속, 높은 유연성 및 환경 보호의 특성을 가지고 있습니다. 성능 지표 및 ...

현대 제조 기술의 발전과 함께 CNC 가공 장비와 이를 지원하는 CAM 시스템이 널리 사용되고 발전해 왔습니다. CAM 시스템에서 생성된 가공 공구 경로(즉, 절삭 모드)는 장비의 가공 작업을 제어하는 핵심입니다. 절삭 경로는 동작 경로 및 방향입니다 ...