제품 기능

- 견고하고 넓은 캐스팅으로 리지드 캐스팅보다 오래 지속됩니다.

- 24 디스크 ATC

- 고속 및 고강성 최대 표면 품질

- 대만 하이윈 리니어 가이드

- 시스템 CNC 컨트롤러

- 완벽한 보호

- 3축 윤활 시스템

- 별도의 핸드 휠

- 공작기계 조명 작업등

- 무작위 기술 문서

- 스핀들 콘 구멍 청소 공기

- 전기 캐비닛 냉각 및 열교환기

- 에어건 청소

- 칩 저장 탱크

- 서보 트랜스포머

- 파운데이션 패드 아이언 및 조절 볼트

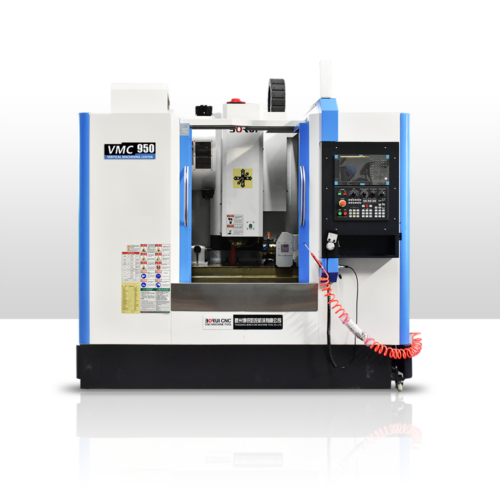

금형 제작용 5축 CNC 수직 머시닝 센터 VMC850의 특징

VMC 850 수직 머시닝 센터는 표준 구성 상태에서 이송축은 X, Y, Z 3좌표 3연결 제어입니다. 이 VMC는 기계 가공 및 금형 제작에 적합합니다. 황삭 가공에서 정삭 가공까지 가공 요구 사항에 맞게 조정할 수 있습니다. 또한 밀링, 드릴링, 태핑, 보링 등과 같은 많은 작업 절차를 완료 할 수 있습니다.

- 머시닝 센터의 공작 기계 850의 주요 부품은 유한 요소 분석을 통해 최적화됩니다.

- 주철은 안정적인 금속 구조의 고강도 주철로 만들어집니다.

- 머시닝 센터 850 기계 본체 베이스, 슬라이드 블록, 작업대, 기둥, 스핀들 박스 및 기타 주요 기초 부품은 고강성 주철 구조를 채택합니다.

- 주철은 안정적인 금속 구조의 고강도 주철로 만들어집니다.

- 머시닝 센터 850 기계는 스 트래들 구조로 되어 있습니다.

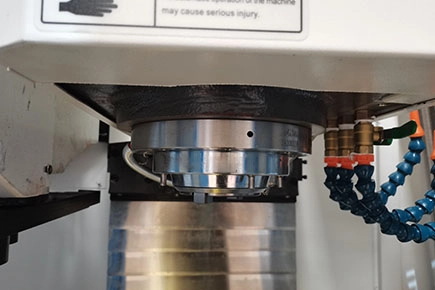

- 서보 스핀들 모터와 결합된 머시닝 센터 850 고속 및 고강성 스핀들 유닛.

- X/Y/Z는 일본 NSK 베어링과 고정밀 수입 잠금 장치를 갖춘 대만 고정밀 고강도 볼 스크류를 채택합니다.

대만 브랜드 CNC 수직 머시닝 센터 스핀들

리뷰

아직 리뷰가 없습니다.