머시닝 센터는 일종의 효율적인 CNC 공작 기계로 오일, 가스, 전기, 수치 제어를 하나로 설정하고 다양한 디스크, 플레이트, 쉘, CAM, 금형 및 기타 공작물 클램핑의 복잡한 부분을 달성 할 수 있으며 드릴링, 밀링, 보링, 확장, 리밍, 리지드 태핑 및 기타 공정 처리를 완료 할 수 있으므로 이상적인 ...

카테고리 아카이브: CNC Machining Center

공작 기계 수동 스크래핑은 공작 기계의 스크레이퍼로 금속 표면을 처리하여 금속 표면의 질감과 광택을 변경하는 목적을 달성하기 위해 일종의 기계 가공 방법입니다. 공작 기계의 수동 스크래핑은 기계 장비에 의해 실현되며 ...

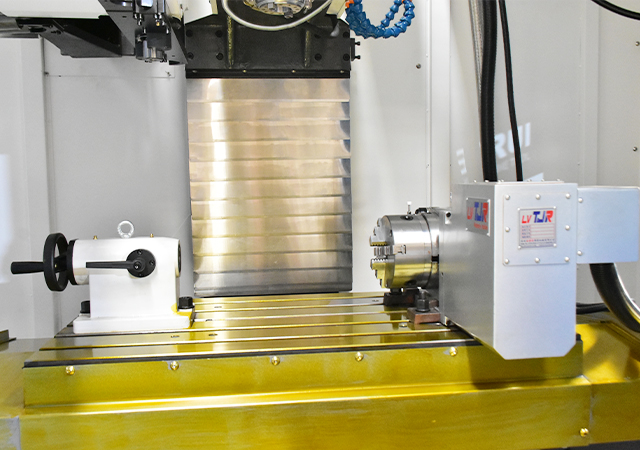

The four-axis machining center is a high-precision, high-efficiency processing equipment that can move and position in three directions (X, Y, Z axes), and can also rotate at the same time, that is, the fourth axis. The four-axis machining center is widely used and can be used to process various metal and non-metal materials, such as…

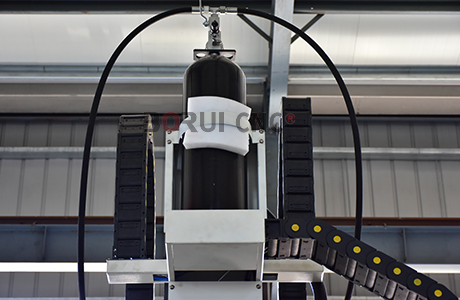

Machine tool nitrogen balance cylinder is a device used to balance the nitrogen pressure of machine tools. It usually consists of a cylinder that contains nitrogen gas and a piston that moves within the cylinder. When the machine tool needs nitrogen, the piston will push outward to push the nitrogen into the machine tool; when…

1. What Are Machining Center Tools: The tool used in the machining center is composed of a universal tool (also known as the working head or the tool head) and a tool handle matching the taper hole at the front end of the spindle of the machining center. In the application, according to…

The performance of numerical control system determines the machining efficiency, forming accuracy and running stability of numerical control machine tools. Numerical control system can control the machine tool to achieve two – axis, three – axis or multi – axis linkage machining. The difference between machining center and ordinary CNC machine tool is…

With the application of five-axis machining center in various fields more and more, the topic of five-axis machining is also increased. For example, why do more and more manufacturers tend to use five-axis equipment to meet the high quality of processing? Today let’s take a look at: Existence Value Of 5 Axis: …

Measurement Of Lead Screw Accuracy: With lead screw accuracy as the main precision of the machine tool, before the overhaul of the machine tool, it is necessary to check the precision of the lead screw to determine the repair measures of the lead screw, or repair, or replace. The inspection of the lead…

The bearing accuracy on the spindle of machine tool should be ISOP5 or above, and for the spindle support of CNC machine tools, machining centers and other high-speed and high-precision machine tools, ISOP4 or above accuracy should be selected; Spindle bearings include angular contact ball bearings, tapered roller bearings, and cylindrical roller bearings….

Longmen processing center is mainly used in aviation, aerospace, automotive, military, energy, information, mold and other industries of parts processing. It is designed to process large and medium-sized complex parts of black and non-ferrous metals. It has the characteristics of high precision, high speed, high flexibility and environmental protection. Its performance indicators and…