Het bewerkingscentrum is een soort efficiënte CNC werktuigmachine, reeksolie, gas, elektriciteit, numerieke controle als één, kan een verscheidenheid van schijf, plaat, shell, CAM, vorm en andere complexe delen van het werkstuk bereiken vastklemmen, kan boring, het malen, het boren, het uitzetten, het ruimen, het stijve onttrekken en andere processenverwerking voltooien, zodat...

Handmatig schrapen van gereedschapsmachines is een soort mechanische bewerkingsmethode waarbij het metaaloppervlak met de schraper op de gereedschapsmachine wordt bewerkt om de textuur en glans van het metaaloppervlak te veranderen. Handmatig schrapen van gereedschapsmachines wordt uitgevoerd door mechanische...

In het huidige tijdperk van snelle ontwikkeling is numerieke besturingstechnologie een noodzakelijk hulpmiddel geworden op verschillende gebieden. Op het gebied van machinebouw zijn CNC-draaibanken een belangrijk onderdeel van de productie-industrie geworden. 30 ° CNC schuine bed draaibank Machine CNC draaibank bed kantelhoek is 30 graden, dit is een...

Draadsnijden is een bewerkingsmethode die wordt gebruikt om onderdelen met schroefdraad te maken. Meestal worden draadsnijmachines, draadfreesmachines, draadsnijgereedschap en andere apparatuur gebruikt voor het bewerken van schroefdraad. Het proces van draadsnijden omvat het snijden van draden op een werkstuk om deze in andere onderdelen te passen. Draadbewerking wordt meestal gebruikt om...

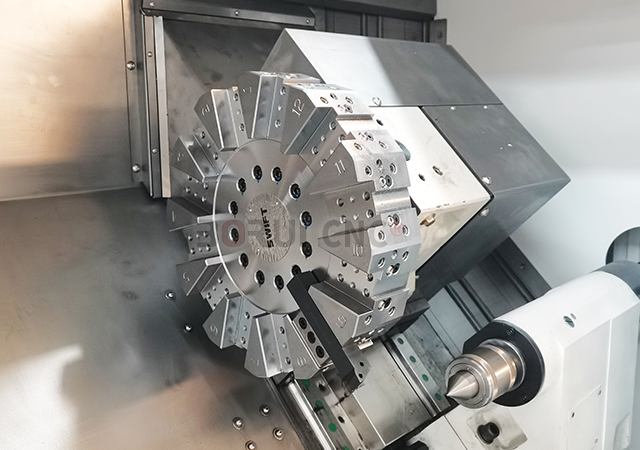

De revolver van de CNC draaibank is een onderdeel dat wordt gebruikt om het draaigereedschap vast te klemmen en te fixeren, en bestaat meestal uit een revolverlichaam, een gereedschaphouder en een blad. Het revolverlichaam is een cilindrisch onderdeel met meerdere klemgaten, dat verschillende soorten en specificaties gereedschaphouders kan klemmen. Het gereedschap...

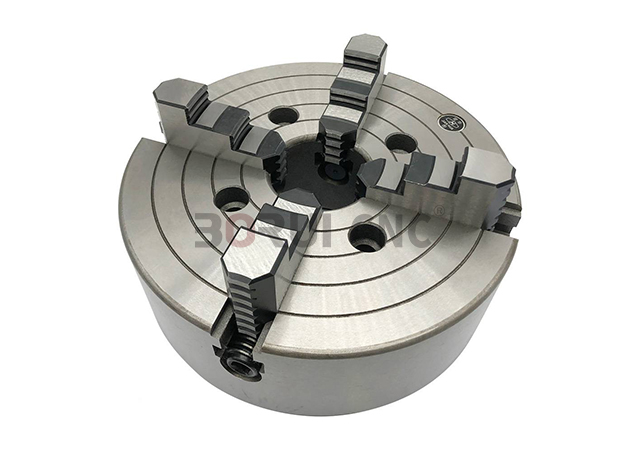

De klauwplaat van de CNC-draaibank is een onmisbaar onderdeel van de CNC-draaibankbewerking. Het is een belangrijk apparaat voor het vastklemmen van werkstukken. Het wordt voornamelijk geïnstalleerd op de spindel van de draaibank. De rotatie van de spindel drijft de rotatie van de klauwplaat aan om te snijden. . Het bepaalt de opspanmethode en...

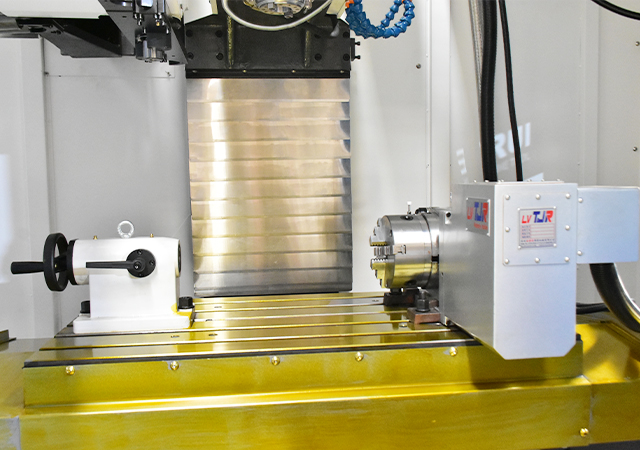

Het vierassige bewerkingscentrum is een zeer nauwkeurig, zeer efficiënt bewerkingsapparaat dat in drie richtingen kan bewegen en positioneren (X-, Y- en Z-as) en tegelijkertijd kan roteren, dat wil zeggen de vierde as. Het vierassige bewerkingscentrum wordt veel gebruikt en kan gebruikt worden voor het bewerken van verschillende metalen en niet-metalen materialen, zoals...

Technische beschrijving van de apparatuur: TCK56 CNC draaibank is een hoog-stijfheid, kosteneffectieve machine tool die op grote schaal kan voldoen aan de high-efficiency verwerking behoeften van kleine en middelgrote onderdelen in diverse industrieën, zoals auto's, lucht-en ruimtevaart, mallen en instrumenten. Algemeen: mechanisch en elektrisch integratieontwerp, compacte structuur, redelijke lay-out, mooie verschijning, 45° hellend bed, rechthoekig...

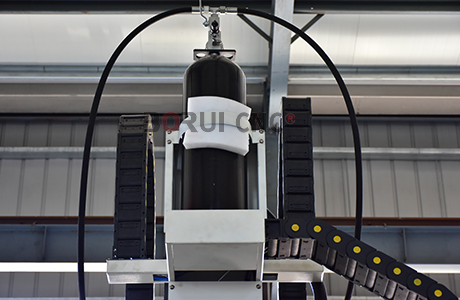

De stikstofbalanscilinder voor bewerkingsmachines is een apparaat dat gebruikt wordt om de stikstofdruk van bewerkingsmachines te balanceren. De cilinder bestaat meestal uit een cilinder met stikstofgas en een zuiger die in de cilinder beweegt. Wanneer de bewerkingsmachine stikstof nodig heeft, duwt de zuiger naar buiten om de stikstof in de...

Verticale CNC draaibanken zijn krachtige machines die veel voordelen bieden ten opzichte van traditionele horizontale draaibanken. Deze machines zijn de laatste jaren steeds populairder geworden, omdat ze verschillende unieke eigenschappen hebben die ze ideaal maken voor een verscheidenheid aan bewerkingstoepassingen. In dit artikel bespreken we enkele van de belangrijkste voordelen van verticale CNC...