Wat is een horizontaal bewerkingscentrum?

Het horizontale bewerkingscentrum injecteert, als een slimme vakman, in stilte vitaliteit in de productie-industrie. Het is een belangrijk hulpmiddel voor moderne industriële productie en heeft de productielijn een krachtige impuls gegeven.

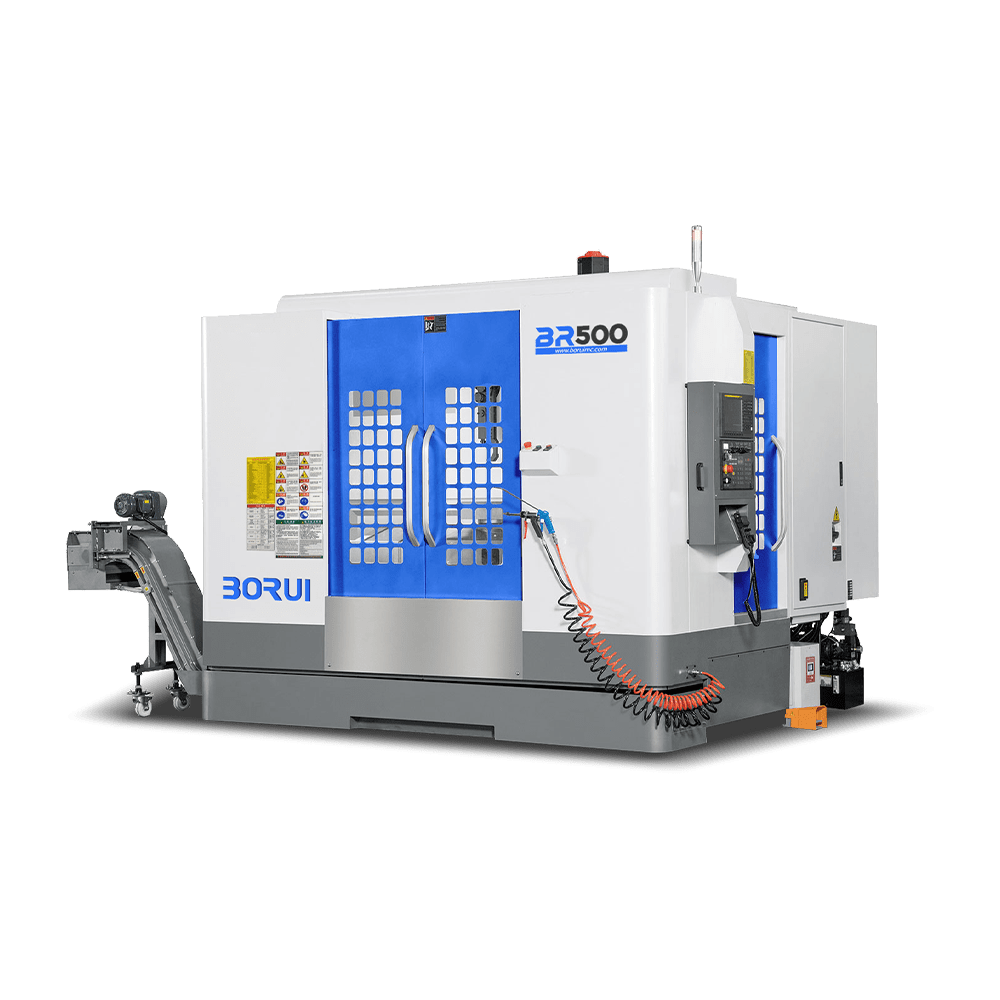

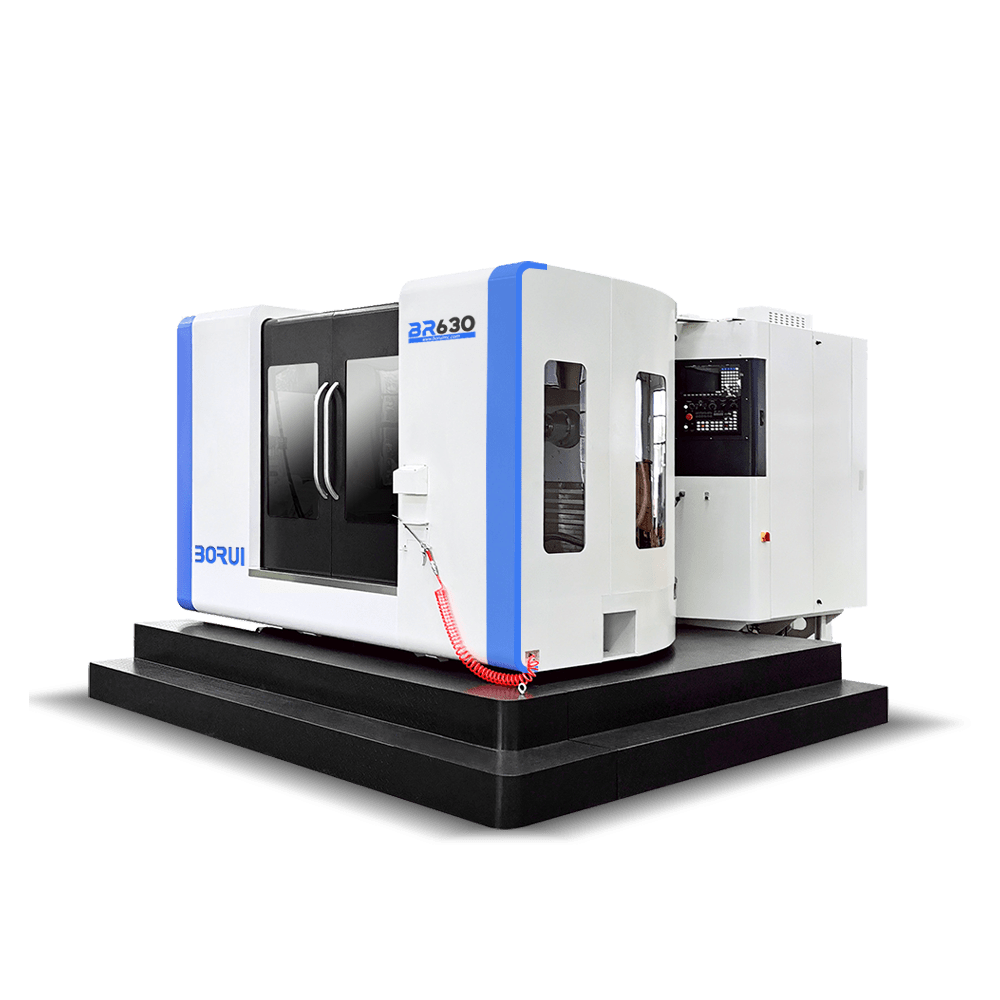

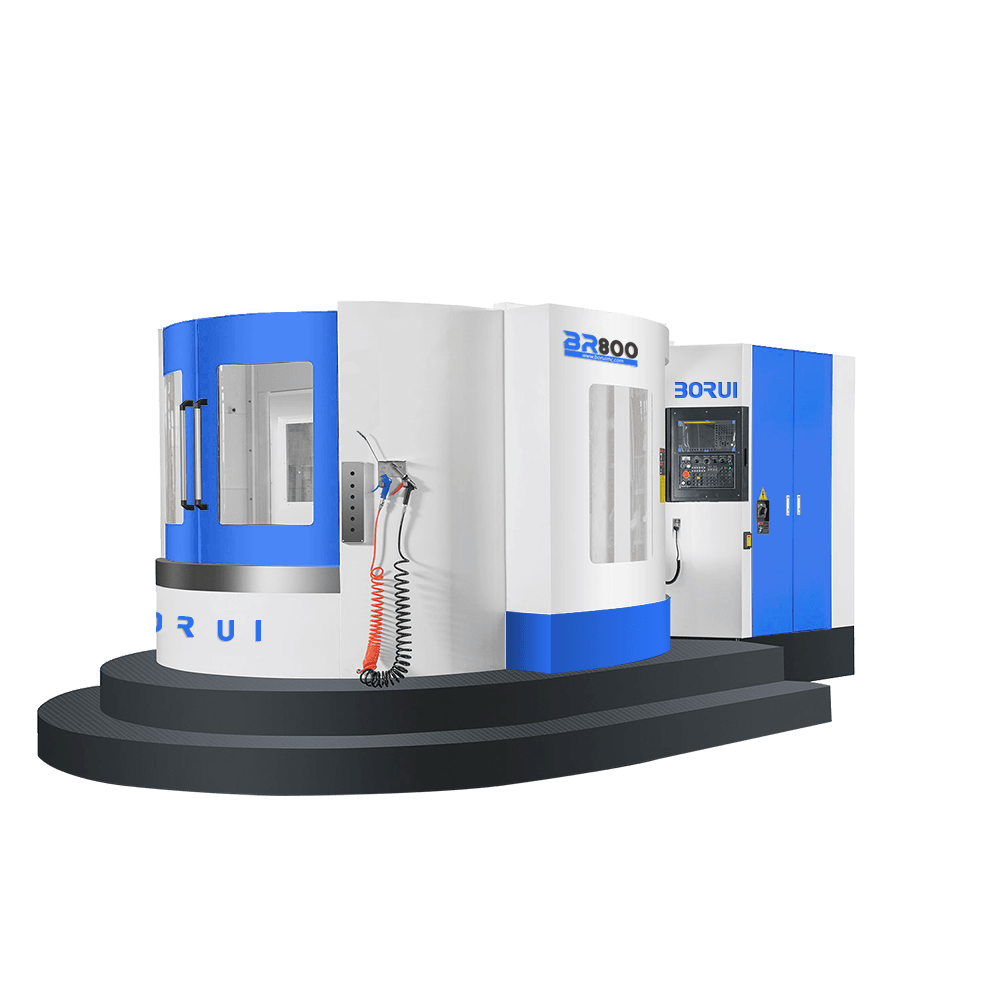

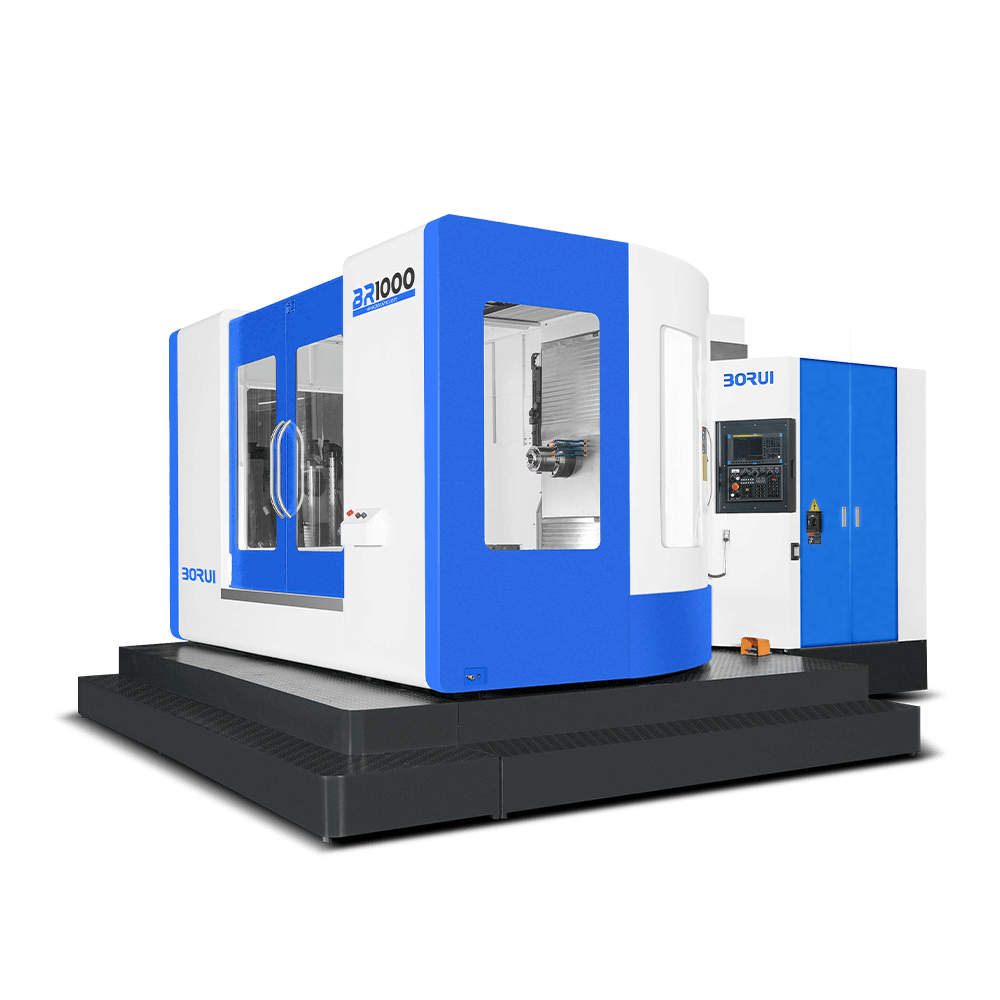

Laten we eerst eens naar het uiterlijk kijken. Het horizontale bewerkingscentrum is als een solide fort, zeer dominant. Alleen al zijn omvang geeft het een onvergelijkbaar gevoel van veiligheid. Het omhulsel is glad en sterk, onverwoestbaar als staal. Dit uiterlijk is niet alleen ontworpen voor de esthetiek, maar ook om de stabiliteit en duurzaamheid van de machine te garanderen.

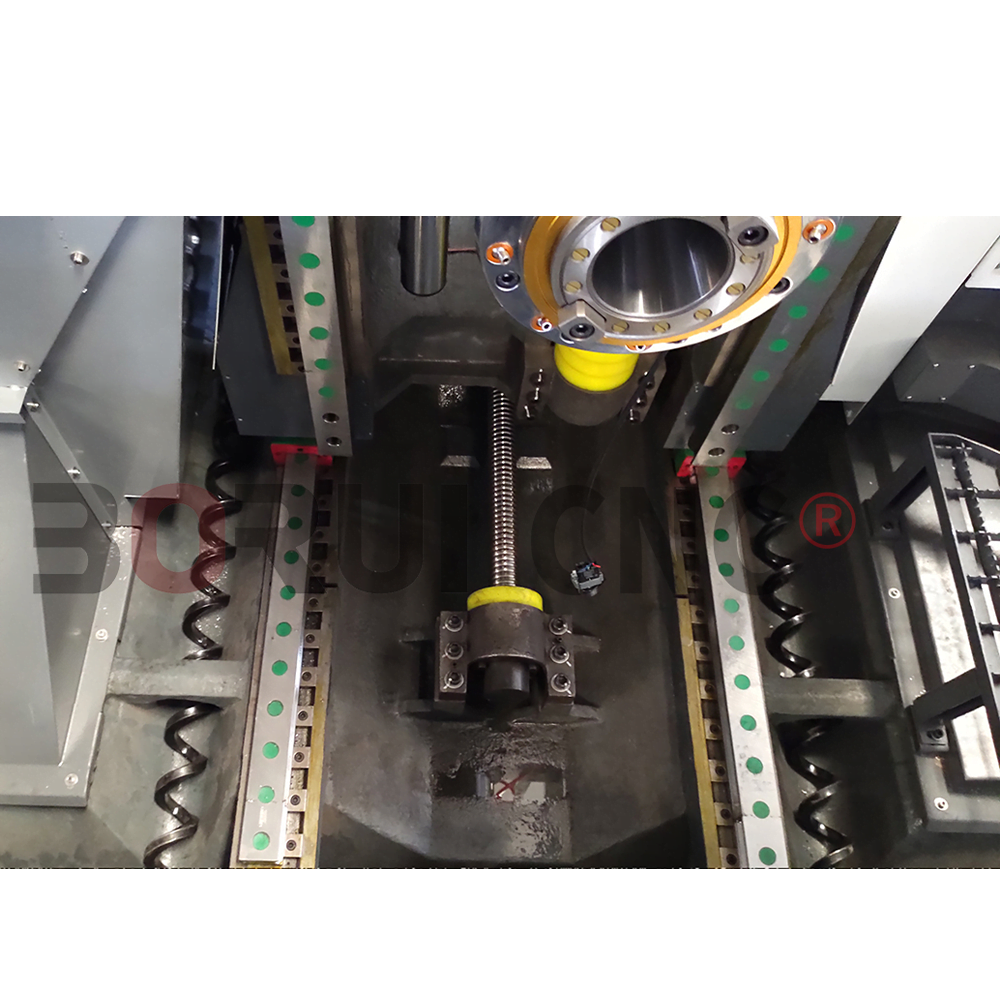

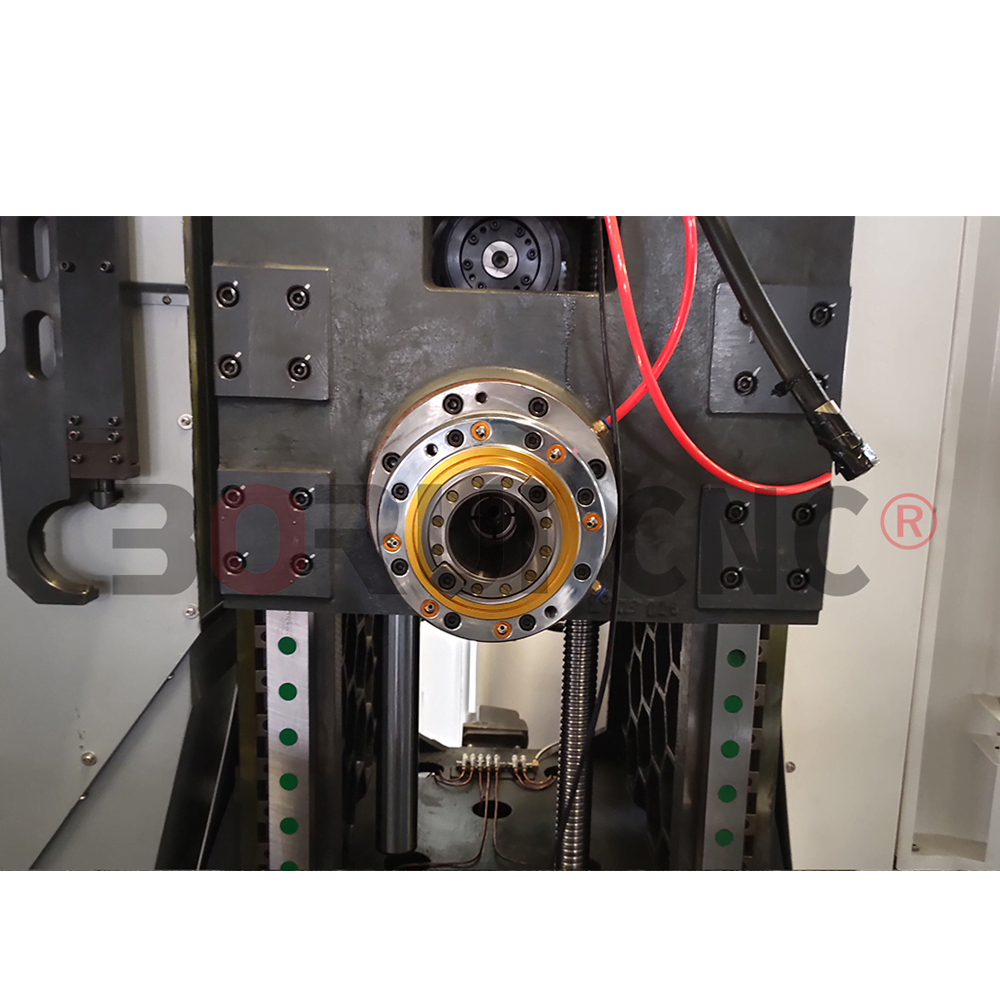

Laten we nu eens binnenin kijken. De binnenkant van het horizontale bewerkingscentrum is een uiterst nauwkeurig werkgebied. Allerlei gereedschappen en onderdelen zijn er ordelijk opgesteld, als een precieze band die rustig een symfonie van fabricage speelt. In deze ruimte is elke bewerking nauwkeurig en krachtig, en samen creëren ze ontelbare nauwkeurige onderdelen, die bijdragen aan de ontwikkeling van de productie.

De functies van het horizontale bewerkingscentrum zijn divers en krachtig. Het kan boren, frezen, kotteren, tappen en andere bewerkingsprocessen uitvoeren en biedt een volledig scala aan ondersteuning voor de productie-industrie. Of het nu gaat om een klein onderdeel of een groot onderdeel, het horizontale bewerkingscentrum kan competent zijn. De verwerkingssnelheid is snel, de precisie is hoog en kan voldoen aan de eisen van de verwerkende industrie voor efficiënt en nauwkeurig.

Daarnaast heeft het horizontale bewerkingscentrum ook de kenmerken van intelligentie. Het is uitgerust met een geavanceerd numeriek besturingssysteem dat automatische bediening en bewaking mogelijk maakt. Door te programmeren kan het de bewerkingstaak zelfstandig uitvoeren, wat de productie-efficiëntie sterk verbetert. Tegelijkertijd kan het verschillende parameters in het bewerkingsproces in realtime bewaken om de stabiliteit en consistentie van de bewerkingskwaliteit te garanderen.

Het horizontale bewerkingscentrum is de steunpilaar van de moderne productie-industrie en biedt een stevige ondersteuning voor de ontwikkeling van de industrie. De opkomst ervan is niet alleen de vooruitgang van de machine-industrie, maar ook de kristallisatie van wetenschappelijke en technologische innovatie. De krachtige functie en hoge mate van intelligentie bieden een solide garantie voor de efficiënte en nauwkeurige productie van de verwerkende industrie.

Het gebruik van horizontaal bewerkingscentrum

- Onderdelenbewerking: een horizontaal bewerkingscentrum kan verschillende onderdelen bewerken, zoals schroeven, tandwielen en assen. De zeer nauwkeurige verwerkingscapaciteit kan de nauwkeurigheid van de grootte en vorm van de onderdelen garanderen om te voldoen aan de behoeften van diverse industriële producten.

-

Mallen maken: Een horizontaal bewerkingscentrum heeft een groot aantal toepassingen op het gebied van de productie van mallen. Het kan frezen, kotteren, boren en andere verwerkingsprocessen van de mal uitvoeren en mallen van hoge kwaliteit maken om aan de productiebehoeften van verschillende producten te voldoen.

-

Graveren en beeldhouwen: Horizontale bewerkingscentra kunnen ook gebruikt worden voor graveer- en beeldhouwprocessen op het gebied van kunst. Met een nauwkeurig besturingssysteem en een verscheidenheid aan messen kan fijn snij- en beeldhouwwerk worden uitgevoerd op metalen materialen om unieke kunstwerken te creëren.

-

Ruimtevaart: Horizontale bewerkingscentra hebben belangrijke toepassingen in de lucht- en ruimtevaart. Het kan de onderdelen van de vliegtuigmotor bewerken, zoals turbinebladen, turbineschijven, etc., om de hoge precisie en betrouwbaarheid van de vliegtuigmotor te garanderen.

-

Autoproductie: Horizontale bewerkingscentra worden ook veel gebruikt in de autoproductie. Het kan auto-onderdelen bewerken, zoals motorcilinderblok, krukas, etc., waardoor de efficiëntie en kwaliteit van de autofabricage verbetert.

Kortom, als efficiënt en nauwkeurig verwerkingsapparaat worden horizontale bewerkingscentra veel gebruikt op verschillende gebieden van de productie. De krachtige functie kan voldoen aan verschillende verwerkingsbehoeften en sterke ondersteuning bieden voor de ontwikkeling van de industrie.

https://www.youtube.com/watch?v=G-bS_opBkXI