Ascomponenten: Het is de belangrijkste component die van invloed is op de bewerkingsnauwkeurigheid van het bewerkingscentrum De rotatienauwkeurigheid is van invloed op de bewerkingsnauwkeurigheid van het werkstuk Vermogen en rotatiesnelheid zijn van invloed op de bewerkingsefficiëntie Automatische verschuivingen, exacte stops en gereedschapswissels die van invloed zijn op de automatisering van de bewerkingsmachine Veelvoorkomende fouten van de spindel van het bewerkingscentrum De bewerkingsnauwkeurigheid...

Tag archieven: 5 Axis Turning And Milling Center

Programmeervaardigheden voor grootschalige CNC-draaibankbewerking 1. De bewerkingsvolgorde van de onderdelen:(1) Eerst boren en dan platte kant (om krimp tijdens het boren te voorkomen).(2) Eerst ruw bewerken, dan afwerken (om de nauwkeurigheid van de onderdelen te garanderen).(3) Eerst grote toleranties bewerken en dan kleine toleranties (om ervoor te zorgen dat het oppervlak van kleine toleranties...

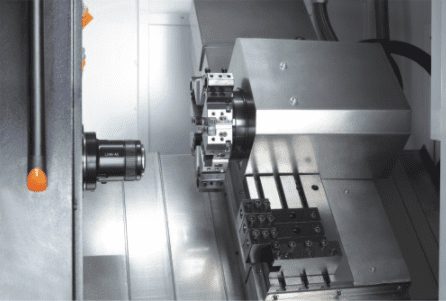

5-assig draai- en freescentrum 5-assige draai- en freestechnieken zijn typisch voor meerassige bewerkingstechnieken. Het 5-assig draai- en freescentrum is het voertuig voor de 5-assige draai- en freestechniek. Het verwijst naar de draaifunctie en integreert functies zoals frezen en boren, met minstens drie functies. Lineaire machineaanvoeras...