1.The basic classification of CNC machining center cutting tools

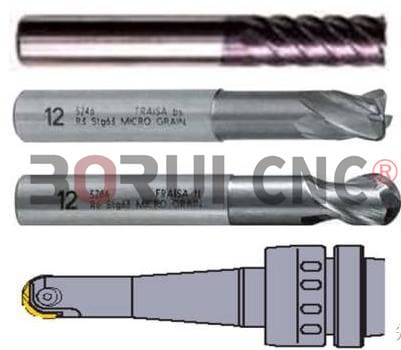

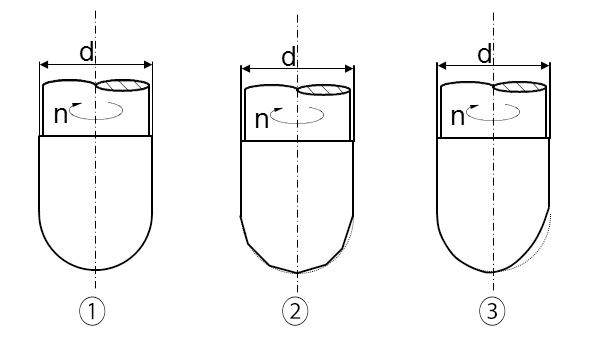

According to the end geometry:

Flat Bottom End Mills

Flat bottom R angle end mill

Ball nose end mill

Indexable insert end mills

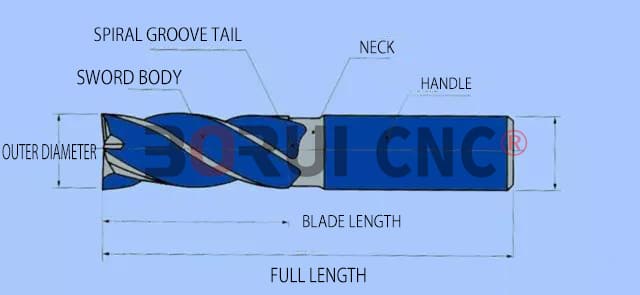

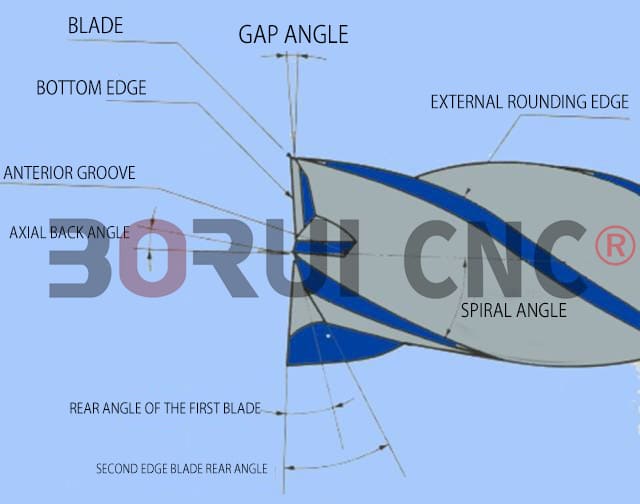

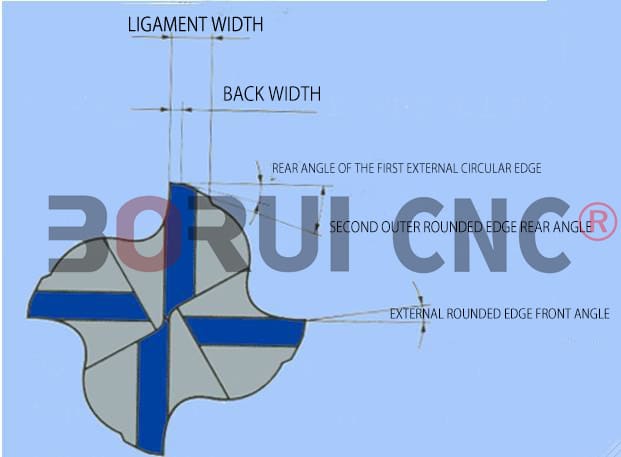

2.Basic geometry of cutting tools

3.Basic geometry of cutting tools

Cutting tools for finishing, the cutting edge must have a good contour accuracy.

Several possible contour deviations of the tool

① Accurate contour;

② Due to the inaccuracy of the grinding process, irregular broken surfaces are generated on the blade;

③ Radius deviation due to inaccurate grinding process.

If the accuracy of the workpiece is very high, you should buy standard certified tools from the tool manufacturer.

Under the premise of ensuring that the maximum overhang length of the tool holder and the tool system does not exceed the specified value, in order to make the spindle run accurately, the radial runout error of the tool must be detected at the tool holder and the cutting edge respectively. If the radial runout error is too large, it will cause severe vibration of the spindle.

4.How to choose the right cutting tool for your machining center

(1) Analyze the specific processing conditions, such as the performance of the spindle and the machine tool, the clamping system of the tool, the lubrication method, etc.;

(2) Analyze the material properties of the workpiece;

(3) Analyze the surface quality and machining accuracy requirements, cost, etc.;

(4) Comprehensive consideration of various factors to make the optimal choice

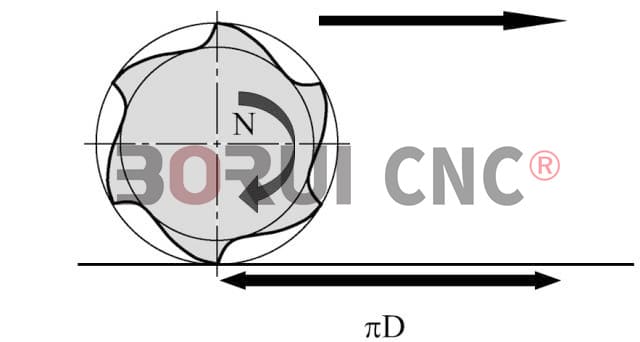

5.Calculation method of high-speed cutting machining parameters

6.Several Important Terms and Machining Parameters in High Speed Cutting

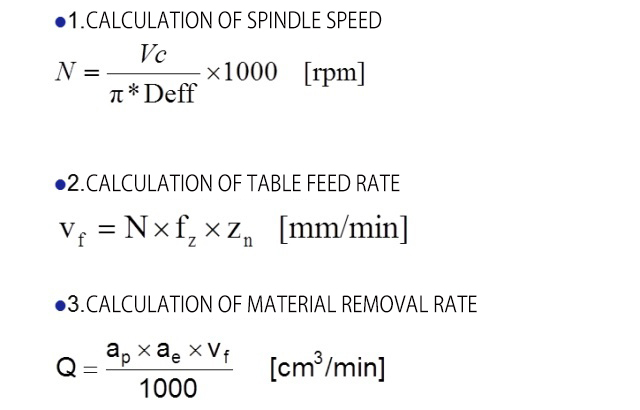

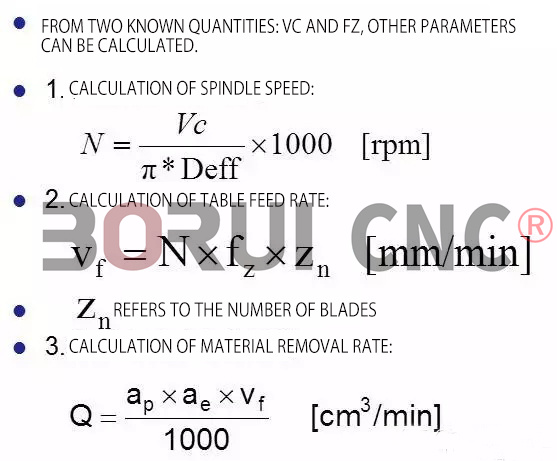

(1) Cutting speed Vc

Calculation formula of cutting speed: Vc=N×p×Deff/1000

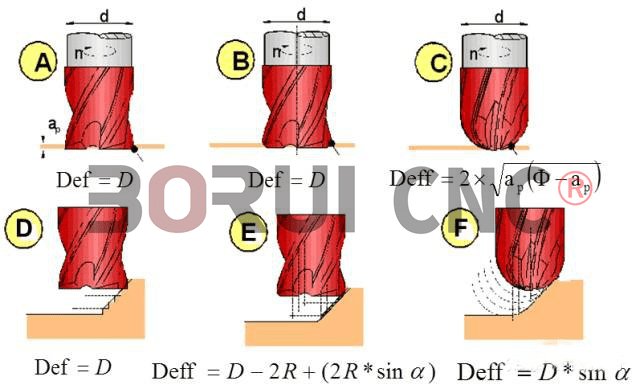

(2) Effective tool diameter Deff

Effective tool diameter and calculation of effective tool diameter.

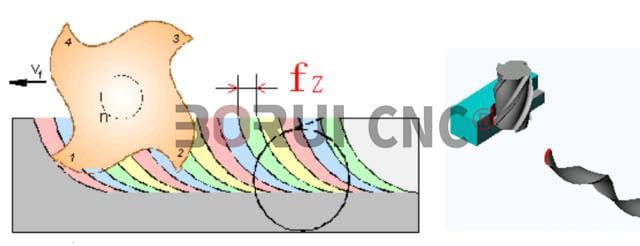

(3) Feed per edge fz

Definition of feed per edge:

How to correctly set the feed per edge of the tool:

Whether the setting of the feed per edge is correct or not has an extremely important influence on the reasonable distribution of the cutting load on the tool.

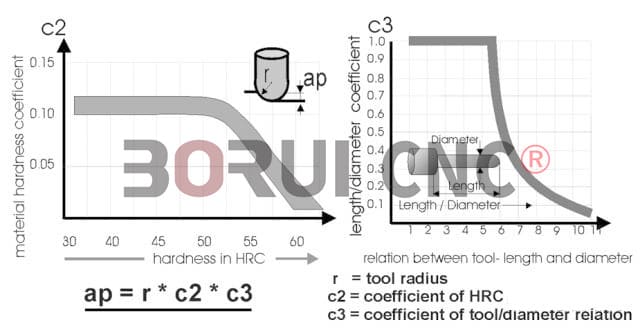

(4) Axial and radial feeds ap & ae

Calculation of axial feed:

Depending on the spindle, tool and material, the actual result will be affected.

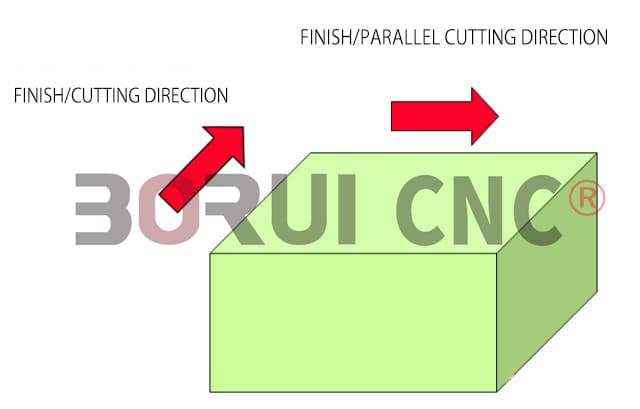

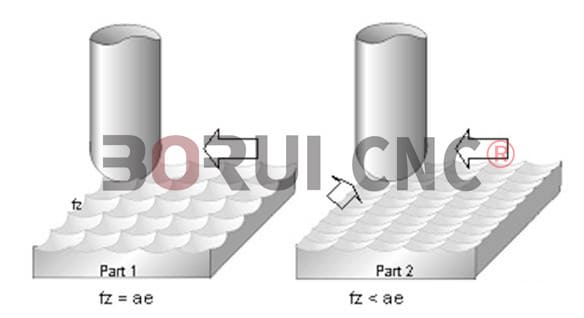

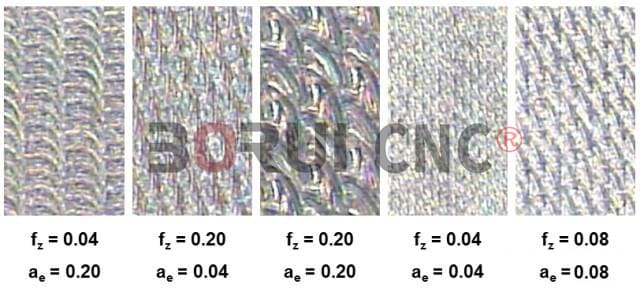

The effect of Ae and Fz on the finish▼

In high-speed machining, the calculation method of each cutting parameter

(6) Setting principles of machining parameters

1. In the process of high-speed machining, the machining parameters must be optimized and cannot be set arbitrarily;

2. The cutting speed Vc value must be set correctly;

3. The feed per edge must be set correctly Quantity fz. Reasonable value can not only maximize the cutting performance of the tool, make full use of the tool, improve the processing quality and efficiency, but also will not affect the service life of the tool, so as to save costs and achieve the purpose of real high-speed machining.