Введение

Landing a job is the primary consideration for every new fabrication shop. In the beginning, securing new clients might appear daunting, but having the correct equipment can take you a long way. Clients in the manufacturing sector have well-defined requirements, be it machine parts, OEM, or finished goods. Matching these conditions involves production in a timely and efficient manner. Finally, cost is a crucial factor for all suppliers. Timely delivery of finished products separates the good fabricator from the bad one. It is necessary to process all units under one roof to meet tight deadlines. Only a workshop equipped with the appropriate equipment can be self-reliant. This article will cover the critical metal fabrication machines and describe how to make the most of them.

6 Essential Machine Tools for Fabrication Shops

The following machine tools can accomplish any task, from cutting to bending. With these tools in your workshop, you are all set to manufacture the highest-quality parts.

Обрабатывающий центр с ЧПУ

A CNC machining center is an automated milling and drilling machine. It is controlled by a computer and runs on software programmed to run various machine operations. At the core of the CNC machining center is the spindle, a vertical arm extending downwards upon the worktable. The milling or drilling tool is attached to the head of the spindle. The spindle can move up and down on the z-axis, while the worktable moves the part on the x and y axes. The spindle rotation is powered by a belt-driven motor, which enables the cutting or drilling tool to work on the object. A CNC machining center drastically limits the waste generated by a workshop by offering high efficiency. It is also faster and more reliable than a manual or mechanical milling machine. For this reason, CNC machining centers are widely utilized in the oil & gas industries and automobile workshops.

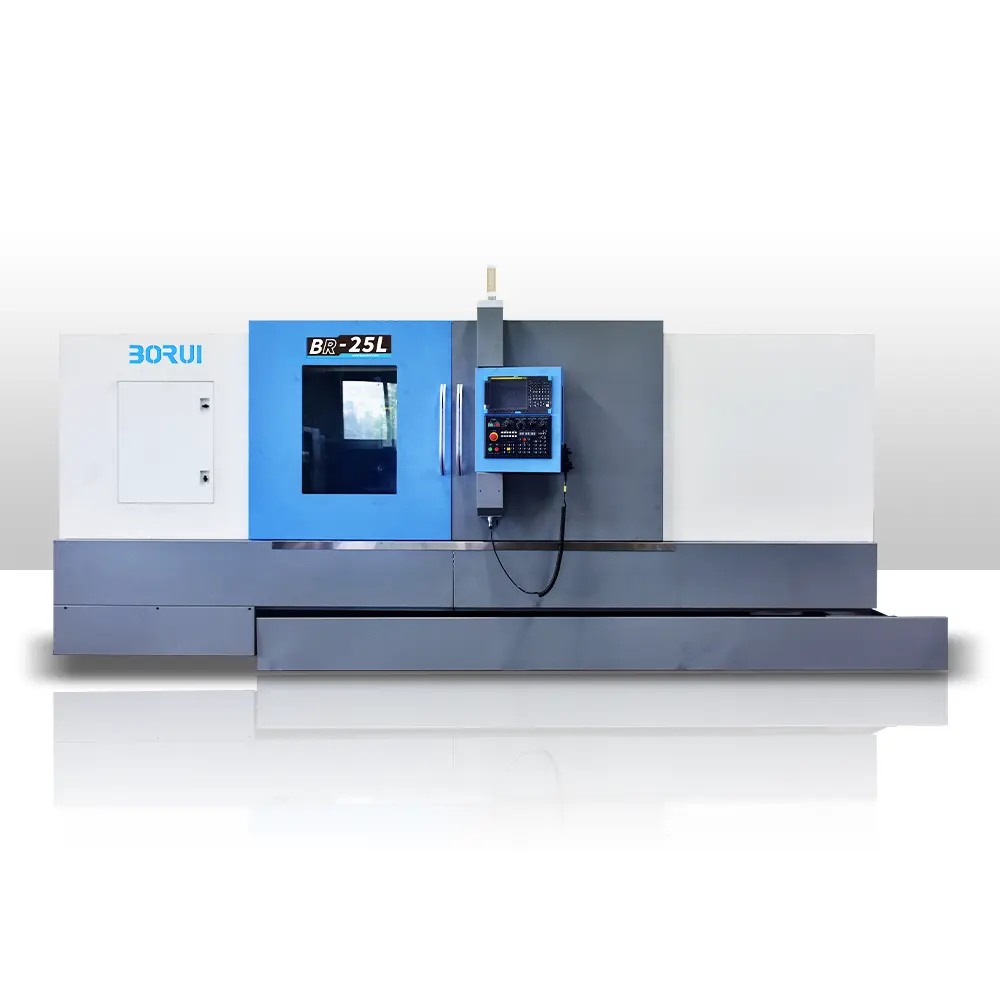

Токарный станок с ЧПУ

The CNC lathe machine automates the working of cylindrical workpieces. Its construction is similar to a mechanical lathe machine, with a central axis containing the spindle with clamps and cutting tools at various turret stations. The workpiece is fixed between the spindle, which is then rotated at a high speed. The cutting and boring tools form the workpiece according to the design provided by the software. Many options are available for the tool turret: y-axis tools, part catchers, bar feeders, and sub-spindles. Like traditional lathes, CNC lathes are ideal for workpieces symmetrical along a central axis. Modern CNC lathe machines can range from 2 axes to 6 or more. They can convert a workpiece from raw material to a finished product, immensely boosting the output and efficiency of fabrication workshops.

Ленточнопильный станок

Every fabrication workshop looking for precise cutting tools should consider the band saw machine. A band saw is a long and flexible metal blade with serrated edges. The band saw machine fixes this blade between two rotating wheels, allowing the blade to cut through various materials easily. It is perfect for cutting versatile shapes like curved or irregular workpieces. It can work on materials like metal, plastic, and wood. The band saw machines come in various configurations and load-balancing models. The minimum angle is determined by the width of the metal band and the kerf size. While the shearing machine is helpful for initial cutting, the band saw machine is indispensable for product finishing. It considerably reduces the amount of labor required for cutting.

Фрезерный станок

The milling machine is also used to cut a workpiece – however – it offers more surface manipulation than the band saw machine. A milling machine consists of a spindle mounted vertically on the work table. The workpiece is fixed below the spindle with a cutting tool mounted at the end. The rotation of the spindle enables the cutting tool operation. It descends vertically or through various axes upon the workpiece. The precise operation of the cutting tool can be adjusted and fine-tuned. The pressure and cutting speed are modified to suit the workpiece material and design. The milling machine is an adaptable workshop tool that can process workpieces with varying tolerances.

Hydraulic Press Brakes

Press brakes are a one-stop solution for all your bending needs. Hydraulic press brakes utilize hydraulic fluid to generate pressure in the pistons. It consists of a ram, die, and punch. The force generated by the hydraulic system is transferred to the ram, which presses a metal sheet vertically to bend it. Hydraulic press brakes offer high tonnage and precision. They are also very versatile. Hydraulic press brakes can bend metals like steel, aluminum, and iron. When purchasing a press brake, you should check your material requirement, sheet dimensions, and tonnage. Hydraulic press brakes cover parts like flanges, hinges, cabinets, automobile panels, brackets, and enclosures.

Ручной токарный станок

The lathe machine is also called the turning tool because it rotates the workpiece on a spindle. It performs operations like turning, sanding, cutting, and drilling. In a manual lathe machine, the spindle is powered by the operator through a foot pedal. The operator also performs the cutting operation with the tool of choice. The workpiece is mounted between the headstock and the tailstock and rotated rapidly. Lathe machines are excellent at making objects with symmetry along a central axis: screws, barrels, pens, and crankshafts. Manual lathe machines are an affordable and robust option that can fulfill many applications for a fabricator.

BORUI – CNC Machines Manufacturer and Supplier

With rapid changes in the global manufacturing industry, more independent fabricators have been empowered as businesses. At BORUI CNC, it is our commitment to provide our valued customers with best-in-class equipment and services. Over 30 years of research and development, our experts have designed CNC machines that can accelerate your manufacturing and boost your factory output. Our 60,000-square-meter factory in Tengzhou manufactures CNC machining centers, milling machines, lathe machines, and band saws. Our global customer base includes fabricators in over 180 countries in Europe, Africa, the Middle East, the USA, and Asia. We encourage you to contact us with your queries. Our professional team would be more than happy to offer you a consultation.