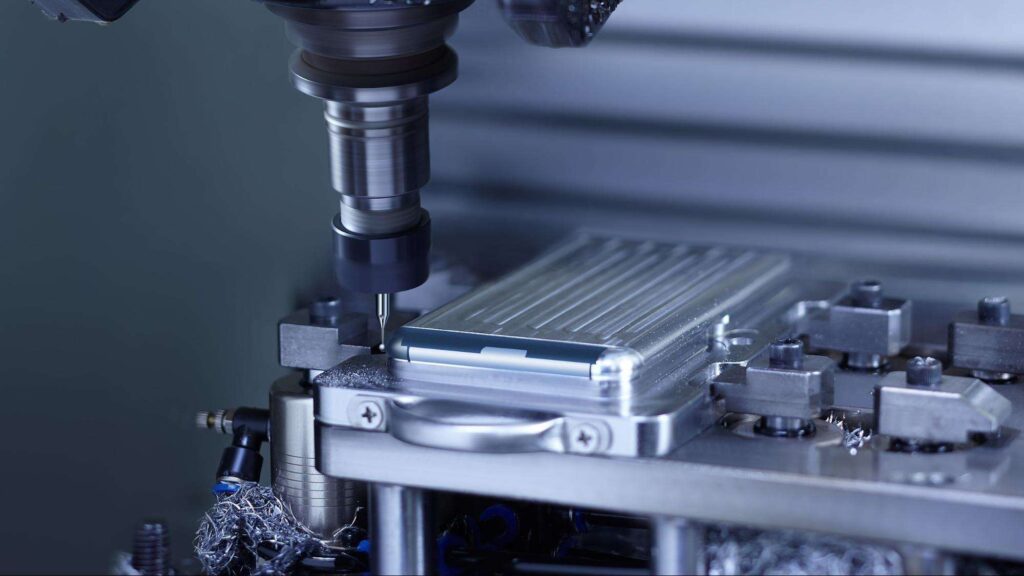

Modern üretim teknolojisinin gelişmesiyle birlikte, CNC işleme ekipmanı ve onu destekleyen CAM sistemi yaygın olarak kullanılmış ve geliştirilmiştir. CAM sistemi tarafından oluşturulan işleme takım yolu (yani kesme modu), ekipmanın işleme operasyonunu kontrol etmek için temeldir. Kesme yolu, takımın hareket yolu ve yönüdür...

Kategori Arşivleri: CNC Machining Center

X,Y,Z Ekseni Tanımı: Takım tezgahının hareket yönünü ve hareket mesafesini belirlemek için, takım tezgahı üzerinde takımın ve iş parçasının göreceli konumunu ve değişen ilişkisini tanımlamak için bir koordinat sistemi oluşturulmalıdır. Başparmağınızı, işaret parmağınızı ve orta parmağınızı uzatın...

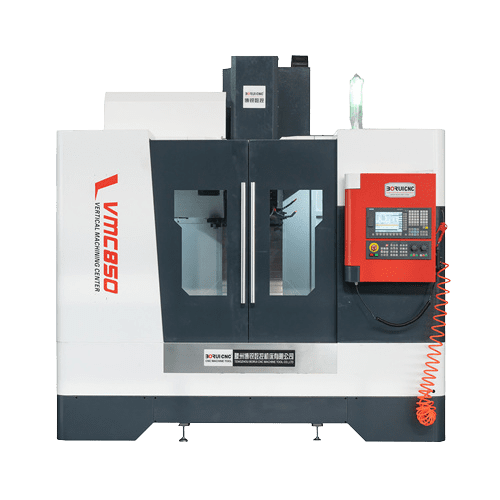

VMC850 dikey işleme merkezi dikey bir çerçeve düzenini benimser, sütun yatağa sabitlenir, mesnet sütun boyunca yukarı ve aşağı hareket eder (Z yönü), kızak yatak boyunca uzunlamasına hareket eder (Y yönü) ve çalışma masası kızak boyunca yanal olarak hareket eder (X yönü) ) Yapı. Yatak, çalışma masası, kayar koltuk,...

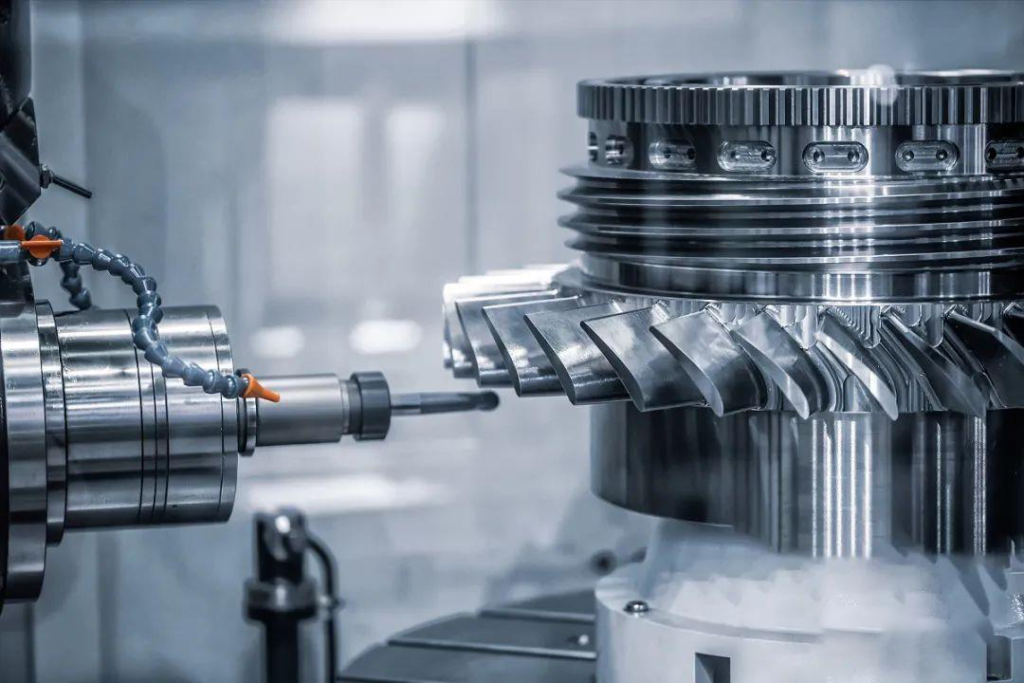

İş mili bileşenleri: İşleme merkezinin işleme hassasiyetini etkileyen ana bileşendir Dönme hassasiyeti iş parçasının işleme hassasiyetini etkiler Güç ve dönüş hızı işleme verimliliğini etkiler Takım tezgahının otomasyonunu etkileyen otomatik vardiyalar, tam duruşlar ve takım değişiklikleri İşleme merkezi iş milinin yaygın hataları İşleme hassasiyeti...

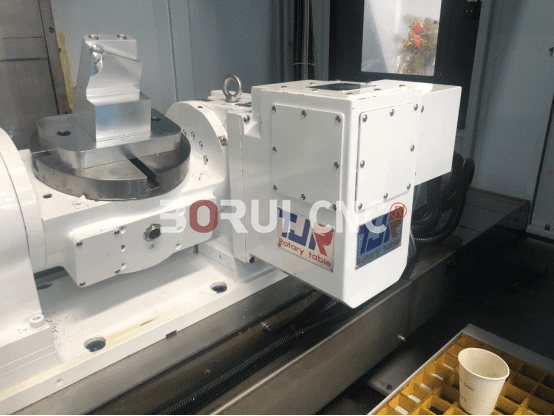

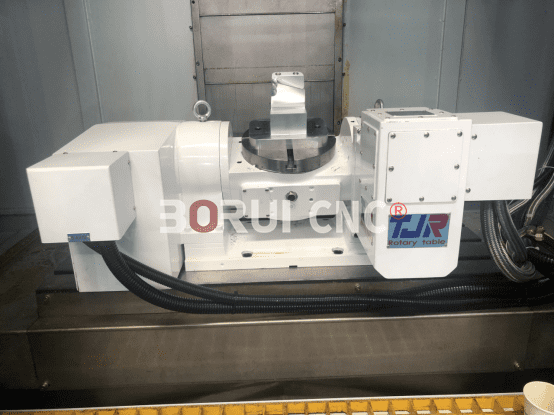

Bunlardan biri döner tabla eksenidir. A ekseni olarak tanımlanan çalışma masasına yerleştirildiğinde X ekseni etrafında döndürülebilir ve A ekseni genellikle 30 derece ila -120 derece aralığında çalışır. Ayrıca saatin merkezinde bir döner tabla vardır ve bu tabla Z ekseni etrafında döndürüldüğünde...

Dik işleme merkezinin nasıl seçileceği durumunuza ve gereksinimlerinize bağlıdır. Örneğin, günlük işleme ihtiyaçlarınız için yeni veya kullanılmış ekipmana ihtiyacınız var mı? Sermaye bütçeniz nedir? Barış zamanında ne tür siparişlerle ilgileniliyor? En nitelikli veya en çok kullanılan süreçler hangileridir vb. Bir kez belirledikten sonra...

İşleme merkezi, delme, raybalama, raybalama, kılavuz çekme ve uç yüzeyleri kazıma gibi çeşitli işleme biçimleri için kullanılabilen bir tür delik işleme ekipmanıdır. Takım tezgahının bağlama düzenine göre, işleme merkezi bir hidrolik işleme merkezi ve bir mekanik işleme merkezi olarak ikiye ayrılabilir. İşleme merkezi...

1. Hangi marka 5 eksenli işleme merkezi iyidir? Beş eksenli işleme merkezlerinin birçok markası vardır. Farklı beş eksenli işleme merkezi markaları farklı konumlandırmaya ve farklı fiyatlara sahiptir. Almanya'nın Demagie, Hammer, İsviçre'nin Baume, Weiliming, Japonya gibi bazı markalar üst düzey pazarda konumlandırılmıştır. Mazak gibi bazı uluslararası birinci sınıf markalar ve...

VMC850 dik işleme merkezinin proses kullanımında, çevre, sıcaklık, nem ve kendi parçalarının kullanımı nedeniyle aşınma, iç kuvvet deformasyonu, aşınma parçalarının kaybı ve diğer faktörler, kapsamlı performansı zamanla değişecek, takım tezgahında küçük sorunların varlığı, hurdaya çıkmasına neden olabilir ...

VMC850 dik işleme merkezinin proses kullanımında, çevre, sıcaklık, nem ve kendi parçalarının kullanımı nedeniyle aşınma, iç kuvvet deformasyonu, aşınma parçalarının kaybı ve diğer faktörler, kapsamlı performansı zamanla değişecek, takım tezgahında küçük sorunların varlığı, hurdaya çıkmasına neden olabilir ...