Ürün Fonksiyonları

- Güçlü ve geniş döküm, sert dökümden daha uzun ömürlüdür

- 24 Diskli ATC

- Yüksek hız ve yüksek rijitlik maksimum yüzey kalitesi

- Tayvan HIWIN lineer kılavuz

- SISTEM CNC KONTROLÖRÜ

- Tam koruma

- Üç eksenli yağlama sistemi

- Ayrı el çarkı

- Takım tezgahı aydınlatma çalışma lambası

- Rastgele teknoloji belgesi

- Mil konisi Delik temizleme havası

- Elektrikli kabin soğutma ve ısı eşanjörü

- Hava tabancasının temizlenmesi

- Talaş depolama tankı

- Servo transformatör

- Temel tampon demiri ve ayar cıvatası

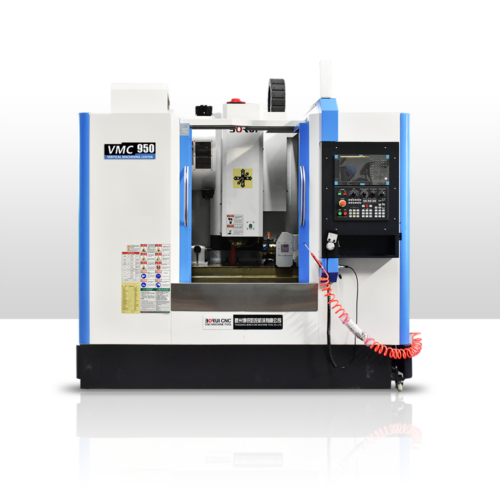

Kalıp Yapımı için 5 Eksenli CNC Dik İşleme Merkezi VMC850'nin Özellikleri

VMC 850 dikey işleme merkezi, standart konfigürasyon durumunda, besleme ekseni x, y ve Z üç koordinat üç bağlantı kontrolüdür. Bu VMC, mekanik işleme ve kalıp yapımı için uygundur. Kaba işlemeden finiş işlemeye kadar işleme gereksinimine uyum sağlayabilir. Ayrıca frezeleme, delme, kılavuz çekme, delme vb. gibi birçok çalışma prosedürünü tamamlayabilir.

- İşleme merkezindeki 850 takım tezgahının ana parçaları sonlu elemanlar analizi ile optimize edilmiştir.

- Ana dökme demir, sağlam bir metal yapıya sahip yüksek mukavemetli dökme demirden yapılmıştır.

- İşleme merkezi 850 makine gövdesi tabanı, kızak bloğu, çalışma tezgahı, sütun, iş mili kutusu ve diğer ana temel parçaları yüksek sertlikte dökme demir yapıya sahiptir.

- Ana dökme demir, sağlam bir metal yapıya sahip yüksek mukavemetli dökme demirden yapılmıştır.

- İşleme merkezi 850 makinesi şekilli bir straddle yapısına sahiptir.

- İşleme merkezi 850 yüksek hızlı ve yüksek rijitlikli iş mili ünitesi servo iş mili motoru ile birleştirilmiştir.

- X/Y/Z, Japon NSK rulman ve yüksek hassasiyetli ithal kilitleme ile Tayvan yüksek hassasiyetli yüksek mukavemetli vidalı mil kullanır.

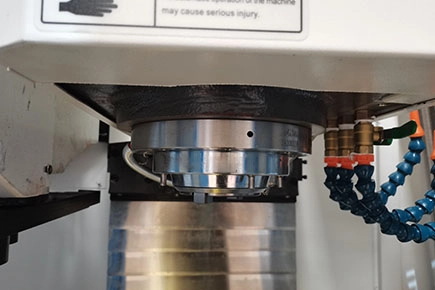

Tayvan Marka CNC Dik İşleme Merkezi Mili

-500x500.png)

Yorumlar

Henüz yorum yok.