We all know CNC milling machines are precise and very powerful. They have quickly replaced the old manufacturing methods. But what are the vital parts of a CNC milling machine that make it such a powerful tool? The operation of these machines is dependent on the functionality of their components.

If one part malfunctions, it can cause the entire machine to malfunction. Everyone knows the significance of these machines, yet they often overlook the intricate parts. However, understanding these parts is crucial, especially if you own a machine or are considering purchasing one. So, let’s start exploring those parts of CNC milling machines.

What is a CNC Milling Machine?

CNC milling machines work on instructions from computerized systems. Their cutters cut and shape the workpiece as per the instructions. What makes CNC milling machines stand out is their precision. You can quickly get as many parts shaped and cut as you want.

Manual machines produce inaccurate outputs. Their work was sluggish, but CNC machines have revolutionized the industry. They use a CNC (Computer Numerical Control) system that ensures 100% precision. The operator gives the machine-programmed instructions in G-code forms.

As a result, the machines produce output that is precisely similar to the instructions. These machines are complex and have many parts. The proper functioning of each part is crucial to their better performance. The manual milling machines were straightforward and did not have many parts. However, their performance was minimal.

Modern machines can cut and shape the material into any complex shape. Such top-notch working with precision is due to their intricate parts and complex components. Understanding them is vital for both operating and buying new machines. Let’s dive in and discuss those parts.

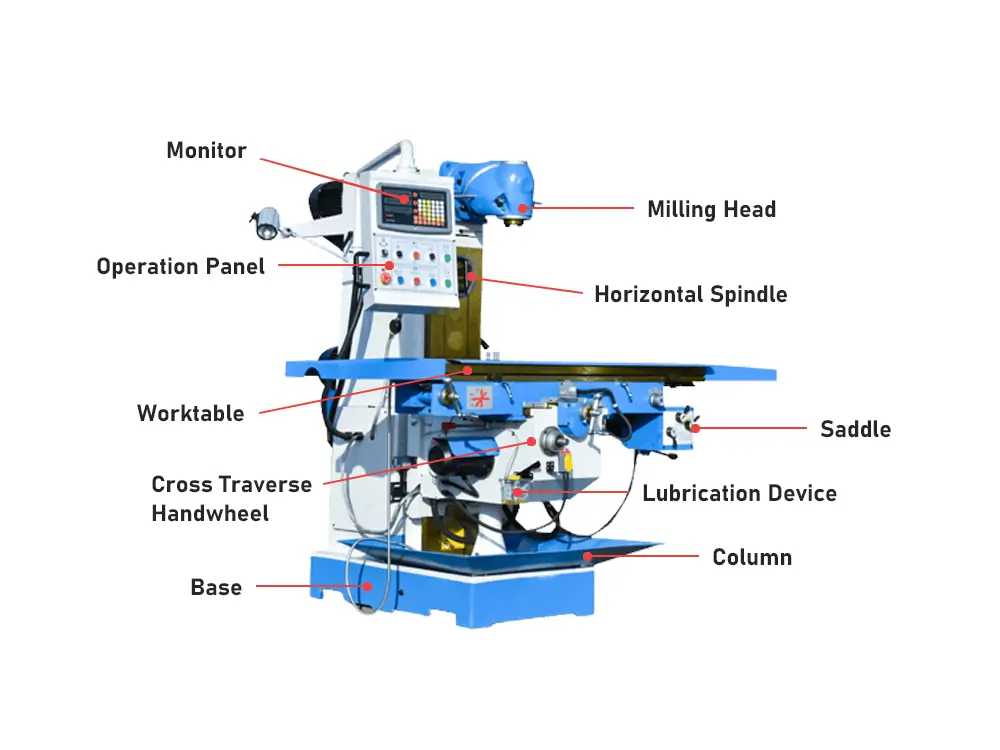

What Are the Fundamental Parts of a CNC Milling Machine?

As I said, these machines are very complex and have numerous small parts. However, eight of them are key components that control the operation of these machines. Let’s explore each part, its purpose, and its function. Borui’s CNC milling machines are high-performance, high-precision, and have a variety of models, and have gained an excellent reputation around the world.

1- Spindle

The spindle is a very critical component in the CNC milling machines. It holds the cutting tools and controls their rotation or movement. You’ll see its position in the column. This component is connected to the motor, and the spindle moves once the motor is switched on.

As a result, the cutting tools move to cut and shape the workpiece. There are two orientations for mounting the spindle: horizontally and vertically. The vertical milling machines have vertically oriented spindles. On the flip side, the horizontal milling machines have horizontal or tinted spindles. If this spindle malfunctions, machines won’t work.

2- Column and Base

The base and columns are fundamental components. Their role is to provide stability to the milling machine. The machine’s base is located at the bottom. It is along the X-axis, and other parts are present on it. Simply put, it carries the burden of all other components of milling machines.

Generally, the base is made with solid material, such as cast iron or granite. Due to such strong material, bases can bear loads of heavy-duty workpieces. The column is just like a base but is vertical in its orientation. It is the part where other components are mounted.

Quick Highlight: For example, the column holds spindles, spindle motors, tool changers, etc. It is along the Y-axis at a 90-degree angle to the base. For easy understanding, assume it is an arm of the machine that holds the necessary parts.

3- Motors and Drive Systems

Motors are the heart of CNC milling machines. All the components depend on the motor for their functionality. There are two main types of motors: servos and steppers. Both are excellent and are used in different CNC milling machines. The drive system controls the movement of components such as worktables and cutting tools.

The servo motors are expensive, but they come with a feedback system. The CNC milling machines with servo motors are 100% precise. The reason is that these motors provide feedback to the CNC system. As a result, it ensures that cutting tools work as per instructions. The stepper motors are cost-effective.

The milling machines that are budget-friendly use stepper motors. Are you wondering about the location of these motors? They are located in the column on the machines. One thing that you must remember is that one machine generally has many motors. Each of those motors is specific for specific parts functionality.

4- CNC Control System

The CNC control system is what makes machines precise. This component is the significant difference between manual and CNC milling machines. This system has multiple components, which are as follows:

- User Interface

- Feedback System

- G-code Interpreter

- Computer and Processor

The user interface is part of the CNC system where operators set parameters. Moreover, it is helpful in feeding the programmed instructions. The computer gets the feedback and provides electrical signals to control the working of motors. The G-code interpreter understands G-coded instructions.

Some modern CNC milling machines consist of a feedback system. This system enhances accuracy and precision. This system becomes active if any part does not follow the computer’s instructions. It tells the computer about the issues. The computer system acts and removes the error, so the cutting tools work according to instructions.

5- Work Table

The work table holds the workpiece during the machining process. It consists of clamps and T-slots that grip the workpiece. This work table sits right in the middle of the machine on the base. When the workpiece is mounted on the worktable, the base provides support for the worktable. This work table can move in many directions.

The movement of the worktable is critical. It allows the workpiece to move around the cutting tools. Some modern milling machines come with four to five-axis movements of the worktable. These machines enable the worktable to move in multiple axes. Such diverse movement in more than one axe makes the machines suitable for complex shapes.

6- Tool Magazine

This component is generally present on high-end CNC milling machines. For your understanding, consider it a storage that keeps the tools. The machine uses these stored tools when it feels the need. For example, machines can use end mills, drills, and taps depending on coded instructions. These tools remain stored in the tool magazine.

This component is on a column adjacent to the spindle. Some machines come with an automated tools changer (ATC) system. This ATC works very closely with magazine tools. Upon receiving instruction, it picks relevant tools from the magazine. Changing the tools would have required manual work each time without this component.

7- Knee and Chip Pan

The knee is located between the work table and the base. It is responsible for the worktable’s vertical movement and controls how high or low it can go. The chip pan is another helpful part, and almost all CNC milling machines are equipped with it.

As you know, cutting tools cut and shape the workpiece. During this process, small pieces (chips) of material are produced. If these particles remain on the machine, they can cause malfunction. So, all machines come with a dedicated chip pan. This part collects the chips and prevents them from accumulating on the machine.

8- Cutting Tools

Cutting tools are the primary components that cut and shape the material. The spindle holds these tools. Inexpensive and simple machines have fewer cutting tools. Conversely, high-end machines with more functionality consist of various cutting tools. Some examples of tools are as follows:

- Reamers

- End Mills

- Face Mills

- Boring Bars

- Thread Mills

- Taps & Drills

- Ball Nose End Mills

Each cutting tool is particular in terms of how it works. Modern machines come with ATC features. The machine changes and picks the appropriate tools according to the needs. These cutting tools are mounted on the spindle of the milling machines. Some tools not used by machines remain in the tools magazine.

Frequently Asked Questions

Q1: Why is CNC milling so expensive?

CNC milling uses a complex working system. It is a computerized operation, and expensive tools make these machines costly. Skilled operators will be needed for their work, further increasing their expenses. However, they are worth the high price as they offer 100% precision and quick turnaround.

Q2: How do the X, Y, and Z axes enhance the precision of a CNC milling machine?

Due to these axes, cutting tools get more directions and paths to move. So they can cut the workpiece from different angles and sides. As a result, these machines can make complex shapes with precision.

Q3: What is the importance of guide rails in CNC milling machines?

Guide rails are responsible for the smooth movement of machine components. They provide a path for tools to move. These paths are smooth and do not cause friction when components move. So, they reduce vibration and friction and improve the correct movement of tools.

Q4: Why is the cooling system so vital for CNC milling machines?

CNC milling machines involve many components. These parts work together, producing heat. This heat can damage the parts and affect the machine’s performance. The cooling system prevents this heat and ensures the parts remain cool. In short, cooling systems improve the life of parts and their functionality.

Conclusion

CNC machines are of utmost value to manufacturers, and their usage is skyrocketing. However, people need detailed information about these machines. Unlike manual machines, they are very complex, and their work depends on the parts and components. In this article, I’ve broken down every part of CNC machines. You will get all the details and all the critical information.