Explore Borui CNC’s advanced CNC Band Sawing Machine, delivering high-performance and precision cutting solutions. Learn more about our cutting-edge technology and services for efficient and accurate production.

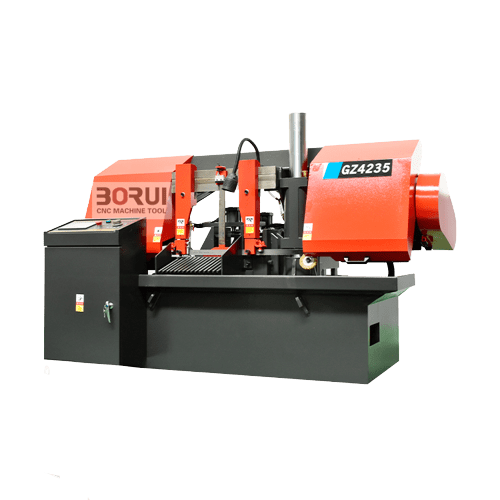

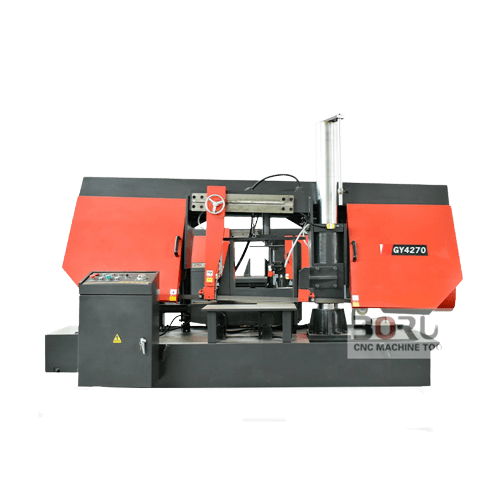

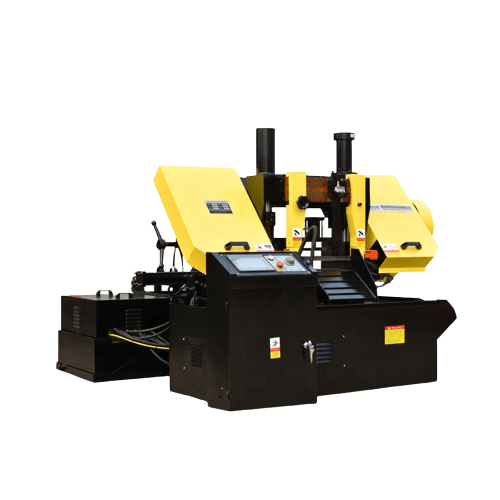

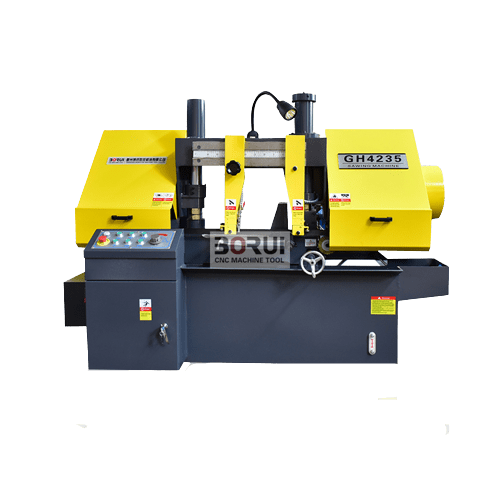

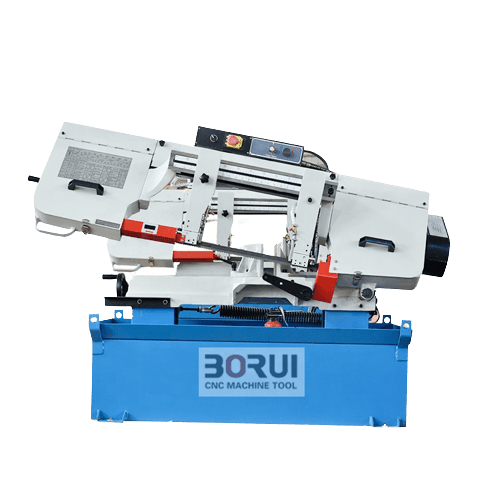

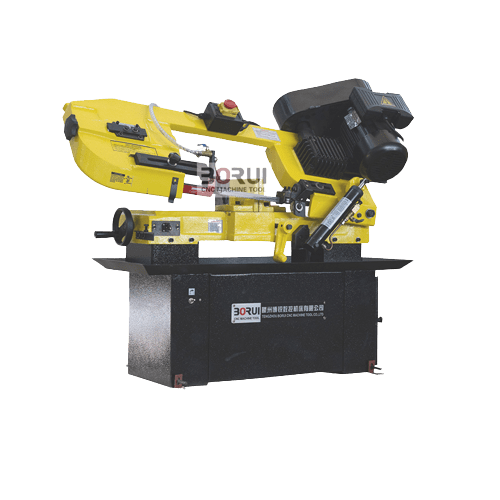

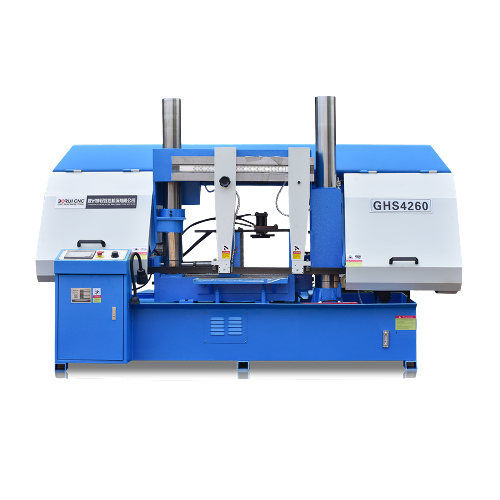

Band Saw Machine

BORUI is one of the top band saw machine manufacturers in China. Our band saw machines adopt a scientific and reasonable guide block structure with stable sawing and high precision. They can meet various sawing needs of customers. We pride ourselves on superior quality. Every saw band machine undergoes strict testing and quality inspection. It ensures the machine is stable, reliable, and has an exceptional lifespan.

Why Choose BORUI As Your Band Saw Machine Manufacturer

Technology Leadership And Innovation

BORUI has always maintained a leading position in saw band machine technology. BORUI band saw machine manufacturer continues R&D and innovation, introducing advanced cutting technology. We always ensure that our products are at the cutting edge of performance and functionality.

Precise Positioning System

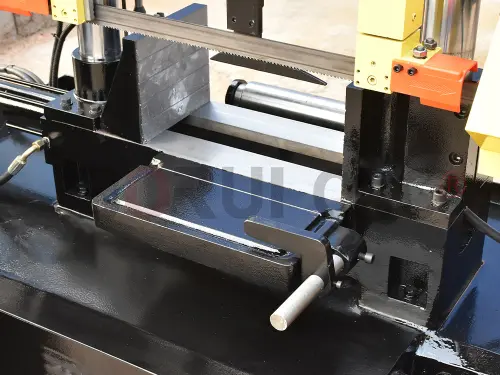

BORUI's band saw machine is equipped with an advanced positioning system. They enable high-precision cutting, reducing waste and ensuring every piece of material meets precise specifications.

Reliability And Durability

BORUI's saw band machine undergoes strict quality control. They have excellent stability and durability. It ensures that the equipment maintains a high level of performance over long periods of operation. It can reduce maintenance and downtime.

Comprehensive Customer Service

We provide a full range of customer service. These include pre-sales consultation, training, installation guidance, and timely response after-sales support. Our team of professionals is dedicated to ensuring customers get the most out of our band saws and resolving any issues they may have.

Metal Cutting Band Saw Machine Buying Guide

What Is A Band Saw Machine?

The band saw machine is a mechanical device used to cut workpieces. Its operating principle is based on a continuously circulating belt with saw teeth. This band saw with serrations is called a band saw blade. It is mounted on two rotating rollers, forming a closed loop. Band saw blades are usually flat but can be angled to suit different cutting needs.

What Is A Saw Band Machine Good For?

The saw wheel of the band saw machine is closely attached to the circular saw belt. The machine will drive the saw belt to complete the cutting operation of the saw wheel. There are two ordinary band sawing machines; one is vertical, and the other is horizontal.

The vertical band saw is a saw frame set vertically. The workpiece will move during cutting to cut the contour curve of the sheet and some parts. You can also replace the saw belt with a file chain when you want to do file repairing, grinding, etc. The usability of the abrasive belt is extreme. The horizontal band sawing machine is different from the vertical band sawing machine. Its saw frame is a horizontal device or an inclined device. The horizontal type is more complicated and is divided into single-column, double-column, and scissor-type band sawing machines. If it is distinguished according to the usage, it is divided into manual and automatic types. Suppose it is divided according to the automation of the controller. In that case, it can be divided into manual type Type (manual feeding by semi-automatic) and fully automatic type (feeding by mechanical followed by automatic cutting).

What Materials Can A Band Saw Machine Cut?

Band sawing machines are mainly used for metal cutting. It is commonly used for sawing carbon steel, rebar, profiles, copper and aluminum, stainless steel, die steel, alloy steel, bearing steel, and ductile iron. Band sawing machines cannot cut metals of any hardness. More complex materials must be sawed with a band saw blade with higher hardness. Otherwise, the service life of the saw blade will be shortened quickly.

With the continuous development of science and technology in recent years, the technology of saw blades has continued to break through, and now ordinary glass, single-crystal silicon, and gemstones have gradually been included in the range of sawing.

Tips For Safe Operation Of The Saw Band Machine

- Check for unsafe hidden dangers such as leakage before starting the machine.

- It is strictly forbidden to open the saw wheel guards on both sides when the band saw is running.

- Never touch the running band saw blade by hand.

- It is strictly forbidden to touch the workpiece under the operation of the band saw blade.

- Wear protective glasses and gloves when folding and removing the band saw blade.

- Be sure to cut off the power of the machine when replacing the band saw blade.

FAQs

Band saw machines can be used to cut metal, wood, plastic, and many other materials. Different types of band saws are available for different kinds of materials and cutting tasks.

Saw band machines have greater cutting depth and higher efficiency than traditional circular saws. It is also capable of handling larger sized workpieces. Because saw band blades are easier to adapt to various sizes than fixed saw blades.

Maintenance of a band saw machine usually includes regularly checking the tension of the saw blade, cleaning the chips from the saw blade and guide wheel, and lubricating the mechanical parts. Ensure safety equipment is working properly.