According to the structure, the sawing machine is divided into horizontal band sawing machine and vertical band sawing machine, and the horizontal type is divided into scissors type, double column and single column type band sawing machine. According to the usage, it is divided into manual type (economical manual feeding and manual cutting of materials) and automatic type. According to the automation program using the controller, it can be divided into manual type (semi-automatic manual feeding) and fully automatic type (automatic feeding and automatic cutting). According to the cutting angle requirements, it is divided into an angle sawing machine (which can cut at an angle of 90 degrees and 45 degrees) without an angle, that is, a 90-degree vertical cutting. Mainly used in metal cutting machine tools, cutting technology and equipment. The double-column horizontal band sawing machine is mainly used for sawing various metal materials such as carbon structural steel, low alloy steel, high alloy steel, special alloy steel, stainless steel, acid-resistant steel, etc.

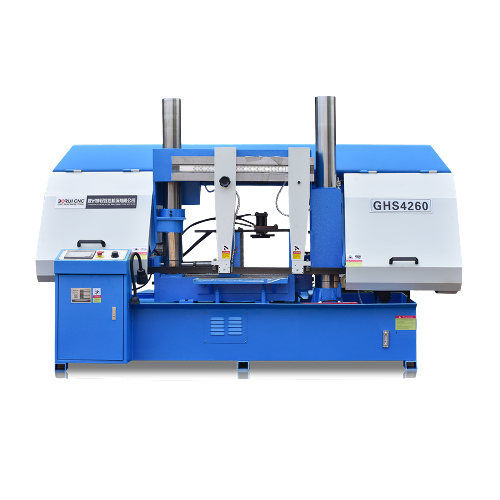

Main components of double-column horizontal metal band sawing machine:

Bottom seat, bed, column, saw beam and transmission mechanism, guide device, workpiece clamping, tensioning device, feeding frame, hydraulic transmission system, electrical control system, lubrication and cooling system. The hydraulic transmission system is composed of a hydraulic circuit composed of pumps, valves, oil cylinders, oil tanks, pipelines and other components and accessories. It completes the lifting and lowering of the saw beam and the clamping of the workpiece under electrical control. Through the speed control valve, the stepless speed regulation of the feed speed can be implemented to meet the needs of sawing workpieces of different materials. The electrical control system is a control circuit composed of an electrical box, a control box, a junction box, a travel switch, an electromagnet, etc., which is used to control the rotation of the saw blade, the lifting of the saw beam, and the clamping of the workpiece, so that it can be operated according to a certain working procedure. Realize the normal cutting cycle.

Square column horizontal band sawing machine performance characteristics:

- Double-column structure to ensure guiding accuracy, stable and reliable sawing.

- Hydraulic clamping with single jaw, convenient for holding materials, suitable for cutting mold materials.

- The band sawing machine is transmitted to the mechanism for precise balance correction, reducing vibration and ensuring that the saw belt is not easy to break and pull teeth.

The advantages of square column horizontal band sawing machine:

In the equipment structure of the double-column horizontal band sawing machine, the double-column is selected to improve the stability of the up and down sawing movement of the saw frame, which is much better than the single-column horizontal band sawing machine in terms of stability. The band saw blade is driven by the saw wheel. It is also an important link that affects the accuracy of sawing. If the saw frame is unstable in the up and down sawing movement, the end face of the workpiece after sawing is also relatively rough, which is also suitable for the next process. It will affect the efficiency and accuracy.

The price advantage of the double-column horizontal band sawing machine is also very significant. When the original horizontal band sawing machine is changed to double-column, the cost of the manufacturer cannot be seen. Compared with the previous single-column horizontal band sawing machine or scissor belt The increase in sales of sawing machines is particularly large, and the after-sales service has cut a lot, so the price of double-column horizontal band sawing machines has not increased, especially the price of equipment purchased directly from the manufacturer will be more favorable.