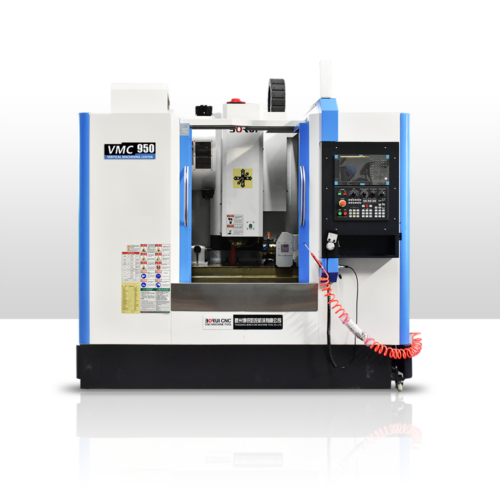

CNC Vertical Machining Center

BORUI is China's top supplier of CNC vertical machining centers. We offer many options, from standard vertical models to 5-axis ones. Each machine has automatic tool changers. They also have state-of-the-art CNC control technology.

As an industry leader, BORUI focuses on designing, making, and selling vertical CNC machining centers. We invest in technology research and development.

We keep launching new products to meet customer needs for advanced manufacturing technology. No matter your needs, you'll find the ideal solution at BORUI.

Request a Quote!Main Features Of BORUI Vertical CNC Machining Center

Automatic Tool Change Function

The vertical machining center has an automatic tool changer and tool magazine. It can change tools automatically. It can be replaced according to the tools used in processing. The CNC VMC machine can change the tool at will. This allows it to process different workpieces.

Process Multiple Processes

From the prior function point. The vertical machining center has an auto tool change. With this function, it can perform multi-process processing in one clamping process. Such as boring, drilling, milling, tapping, and tapping.

Function to Expand The Number of Axes

According to customer needs, there are written workpieces. Such as impellers, blades, shafts, and propellers. The four-axis or five-axis functions can be expanded according to customer product requirements. The CNC vertical machine center has the function of increasing the number of axes. It can extend the functions of four axes, five axes, and many axes.

Multiple Machining Surfaces

It is known that the vertical machining center can expand the number of axes. So, the workpiece can be clamped after the vertical machining center adds axes. Then, it can process many surfaces at once. It avoids the accuracy error of multiple clamping. It also saves time for manual clamping of workpieces.

What BORUI CNC vertical machining center manufacturer Can Provide You

High Quality Product

BORUI CNC vertical machining center manufacturer is committed to providing high-quality VMC machines. Our CNC vertical machining center undergoes precision design and strict quality control. It ensures stable performance, high precision, and durability of the machine.

Widely Used

BORUI's VMC machining center is widely used in various industries. These include aerospace, automobile manufacturing, electronics, medical equipment, and other fields.

Customer Service

BORUI VMC machine manufacturer focuses on customer satisfaction. We provide comprehensive pre-sales consultation, in-sales support, and after-sales service. We can ensure customers have a satisfactory experience throughout the purchase and use process.

International Market

BORUI is one of the top CNC vertical machining center manufacturers in China. Our products also have a particular influence in the international market. BORUI actively expands the global market by establishing cooperative relationships.

CNC Vertical Machining Center Guide

What is A CNC Vertical Machining Center?

You are not unfamiliar with CNC vertical machining centers. Vertical CNC machining centers have reached a 50% use rate in the CNC machine tool market. It is conceivable that vertical machining centers are used in various processing enterprises. Many companies favor it. The vertical machining center integrates the functions of many other CNC machine tools. Such as boring machines, drilling machines, milling machines, and other machine tools.

What Can You Create With A BORUI CNC Vertical Machining Center?

How to Purchase A CNC Vertical Machine Center?

Before choosing a vertical CNC machine, ask yourself the following questions:

- What industry are you in?

- What type of products do you want to produce?

- What is the size of the workpiece you want to process? Include length, width, and height.

- Can the vertical machining center create more significant benefits for you?

- What is your budget for purchasing VMC machines?

Choosing The Right CNC Vertical Machining Center Manufacturer

Your VMC machine has different table sizes, the stroke of each axis, and the spindle speed.

Specific needs depend on the different sizes and types of workpieces being processed.

At BORUI, you can always find a CNC vertical machining center with low price and good quality.

Request a Quote!

FAQs About CNC Vertical Machine Center

Yes. Most VMC machining centers have automatic tool switching (ATC) functionality. Therefore it can automatically change different tools during a program run. This can adapt to different processing needs.

Machining accuracy depends on the specific machine model and manufacturer. Generally speaking, CNC Vertical Machining Center can achieve high-precision machining. It can meet the requirements of many precision parts. For specific accuracy, please view our product list above, or contact us to help you choose.

CNC Vertical Machining Center programming usually uses specialized CNC programming languages. Such as G code and M code. Programmers write these codes that describe the movement and operation of the tool on different axes.

Yes. Our CNC Vertical Machining Centers have multi-axis control capabilities. For example, three-axis, four-axis, and five-axis. It can move the tool in many directions simultaneously to achieve more complex machining tasks. See the difference between 3-axis and 5-axis.

Maintenance and servicing requirements vary depending on the specific model and manufacturer. Generally includes regular lubrication, tool inspection and replacement, axis calibration, and CNC system maintenance. Operators should follow the maintenance manual provided by us. Contact us to purchase.

-500x500.png)