Product Functions

- Strong and wide casting lasts longer than rigid casting

- 24 Disc ATC

- High speed and high rigidity maximum surface quality

- Taiwan HIWIN linear guide

- SYSTEM CNC CONTROLLER

- Full protection

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

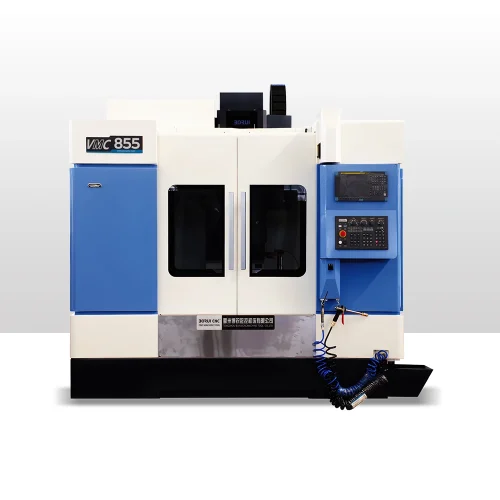

Features of 5 Axis CNC Vertical Machining Center VMC850 for Mold Making

VMC 850 vertical machining center, in the standard configuration state, the feed axis is x, y, and Z three coordinate three linkage control. This VMC is suitable for mechanical processing and mold making. It can adapt to the processing requirement from rough machining to finish machining. It can also finish many working procedures like milling, drilling, tapping, boring, etc.

- The main parts of machine tool 850 in the machining center are optimized by finite element analysis.

- The main cast iron is made of high-strength cast iron with a stable metal structure.

- Machining center 850 machine body base, slide block, workbench, column, spindle box and other main foundation parts adopt high rigid cast iron structure.

- The main cast iron is made of high-strength cast iron with a stable metal structure.

- The machining center 850 machine has a shaped straddle structure.

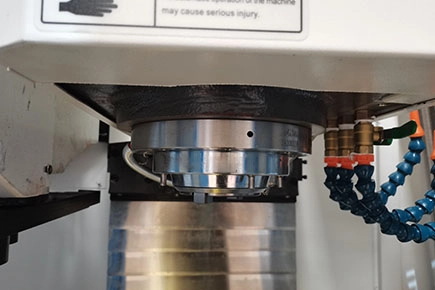

- Machining center 850 high speed and high rigidity spindle unit combined with servo spindle motor.

- X/Y/Z adopts Taiwan high-precision high-strength ball screw with Japanese NSK bearing and high-precision imported locking.

Taiwan Brand CNC Vertical Machining Center Spindle

-500x500.png)

Reviews

There are no reviews yet.