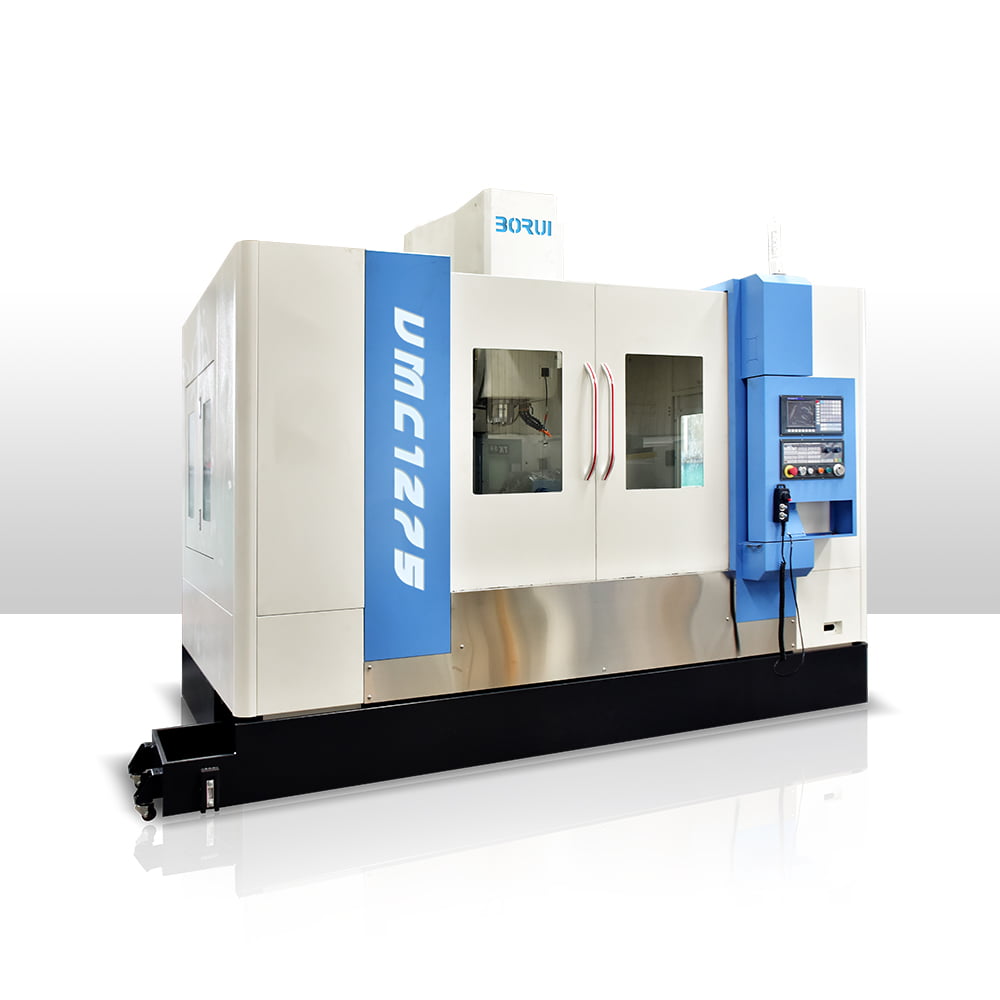

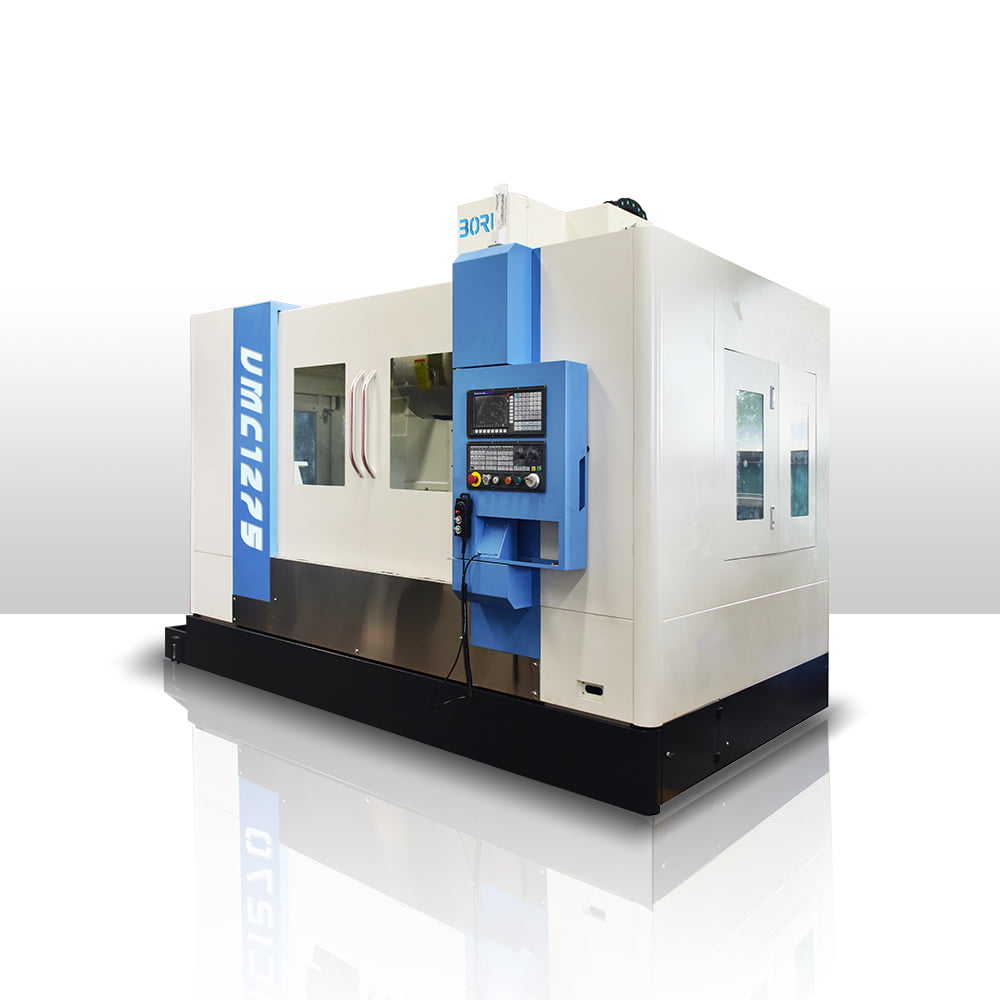

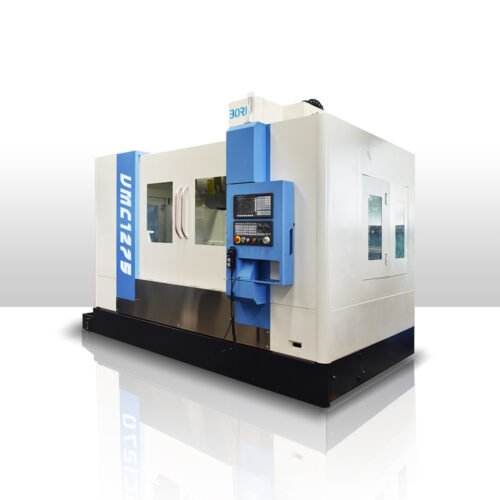

Features Of VMC1275 Vertical CNC Machining Center

- Direct drive spindle structure, low noise

- Three axis guide rail adopts brand linear rolling guide.

- Systems can be selected according to customer requirement

- 24 Disc ATC

- SYSTEMCNC CONTROL

- SIEMENS, KND, FANUC, Mitsubishi, GSK, and other operating

- Full protection

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

Technical Parameters Of VMC1275 CNC Vertical Machining Center

| SPECIFICATION | VMC1275 | |

|---|---|---|

| X Y Z axis travel | mm | 1200/750/600 |

| The distance from spindle nose to worktable surface | mm | 120-720 |

| The distance from spindle center to column surface | mm | 775 |

| T-slot | mm | 18/100/7 |

| Worktable size | mm | 1300*700 |

| Worktable max loading | kg | 800 |

| Spindle speed | rpm | 8000 |

| Main motor | kW | 11/15 |

| spindle taper | BT40(BT50) | |

| Rapid traverse speed | m/min | 36/364/36 |

| Cutting feed speed | mm/min | 1-10000 |

| Positioning accuracy | mm | ±0.0075 |

| Repeat Positioning accuracy | mm | ±0.005 |

| Magazine tool capacity | pcs | 24(disc type) |

| Machine overall size | mm | 3870*2900*2580 |

| Machine weight | kg | 6500KG |

Advantages Of 1275VMC Machining Center

- Precision linear guideways on X/Y/Z axes provide high-speed rapids.

- High-quality castings provide a solid structure and foundation.

- Full enclosed way covers.

- Direct drive servo motors on all axes.

- Disc type ATC.

- High-speed rapids. Standard-higher speeds are available on axes and spindles.

- Optional 5 axis, 4 axis are available.

-500x500.png)

Reviews

There are no reviews yet.