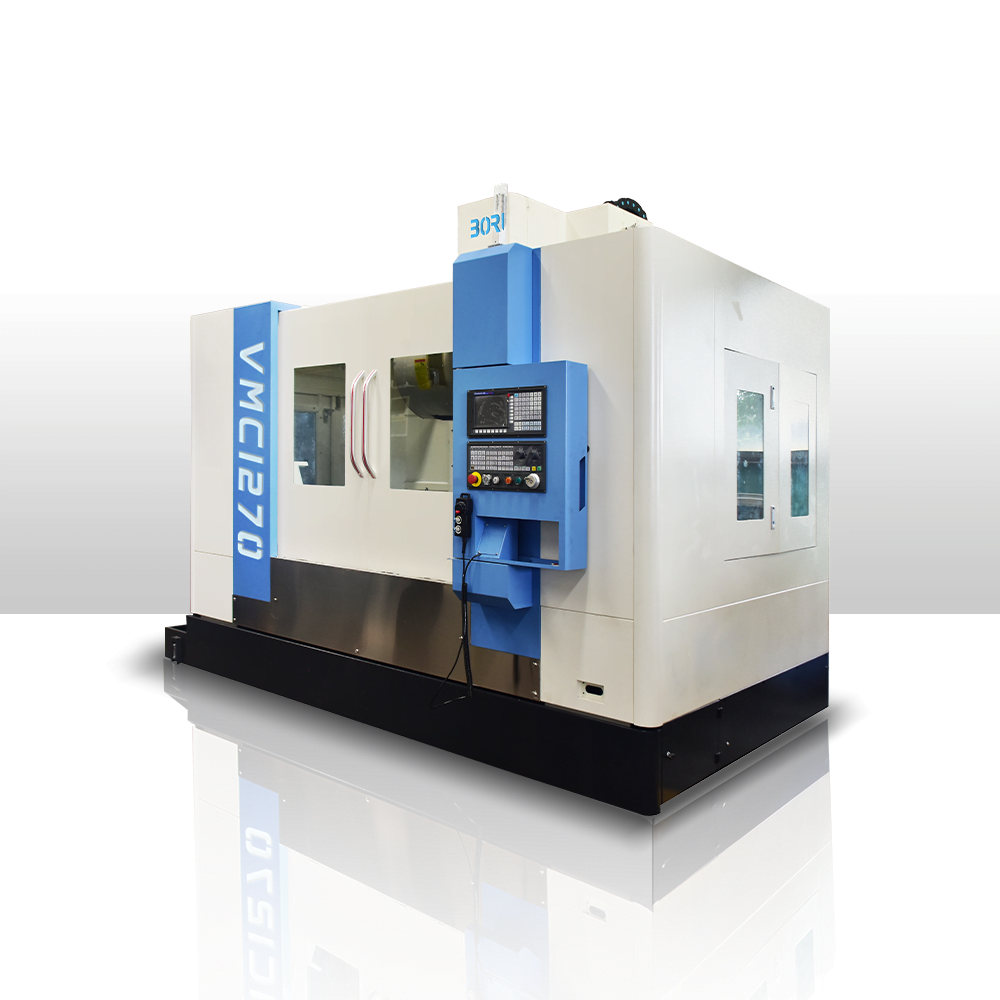

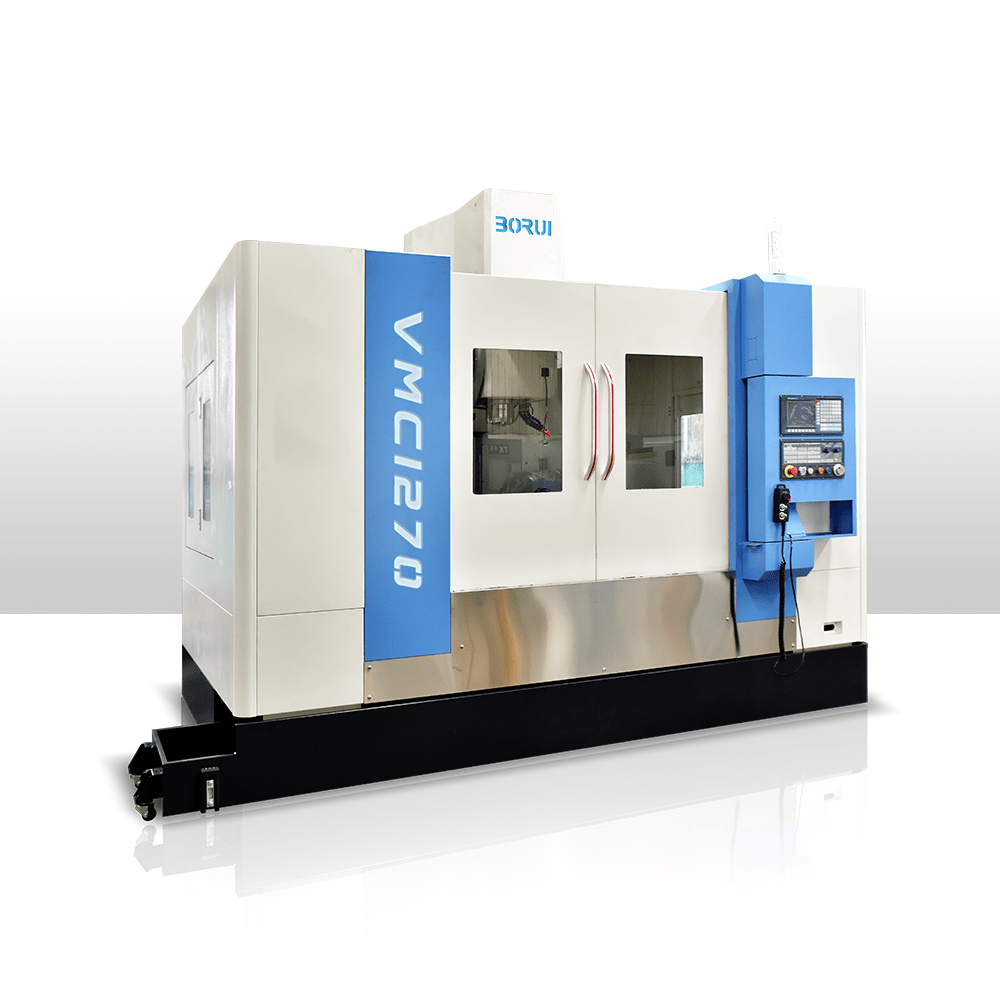

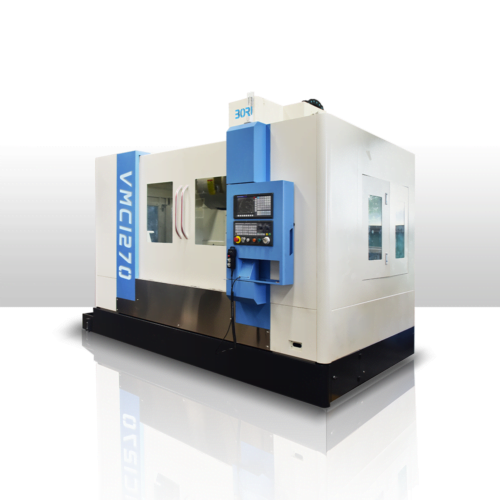

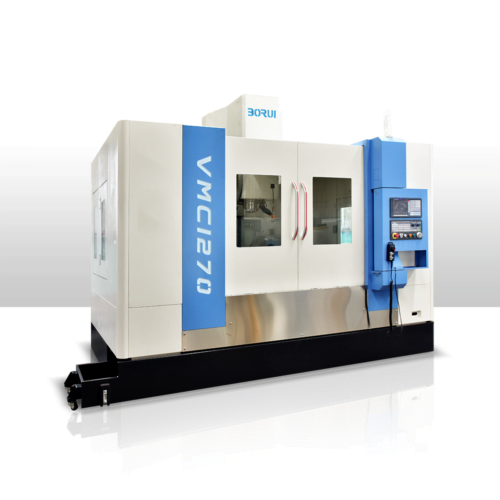

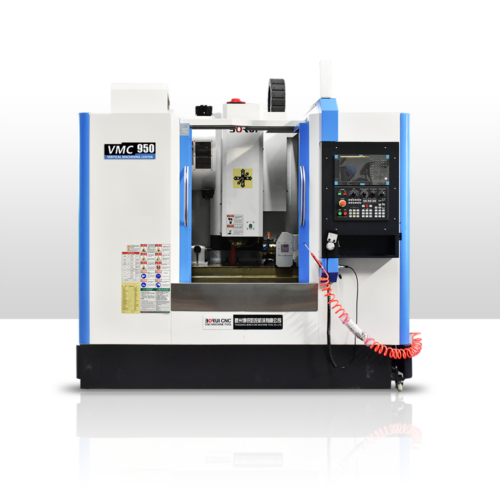

5 Axis VMC Machine Features

- Table: 1300x700mm

- Model: VMC1270

- Vertical frame layout

- 24 Disc ATC

- Spindle speed: 8000 / 10000 / 12000

- The spindle is stepless in its speed range

- Taiwan HIWIN linear guide

- Systems can be selected according to customer requirement

- SYSTEMCNC CONTROL

- SIEMENS, KND, FANUC, MITSUBISHl, and other operating

- Full protection

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

- Send Inquiry

Product Video Display

Technical Parameters Of 5 Axis CNC Vertical Machining Center

| Specifications | Units | VMC1270 |

|---|---|---|

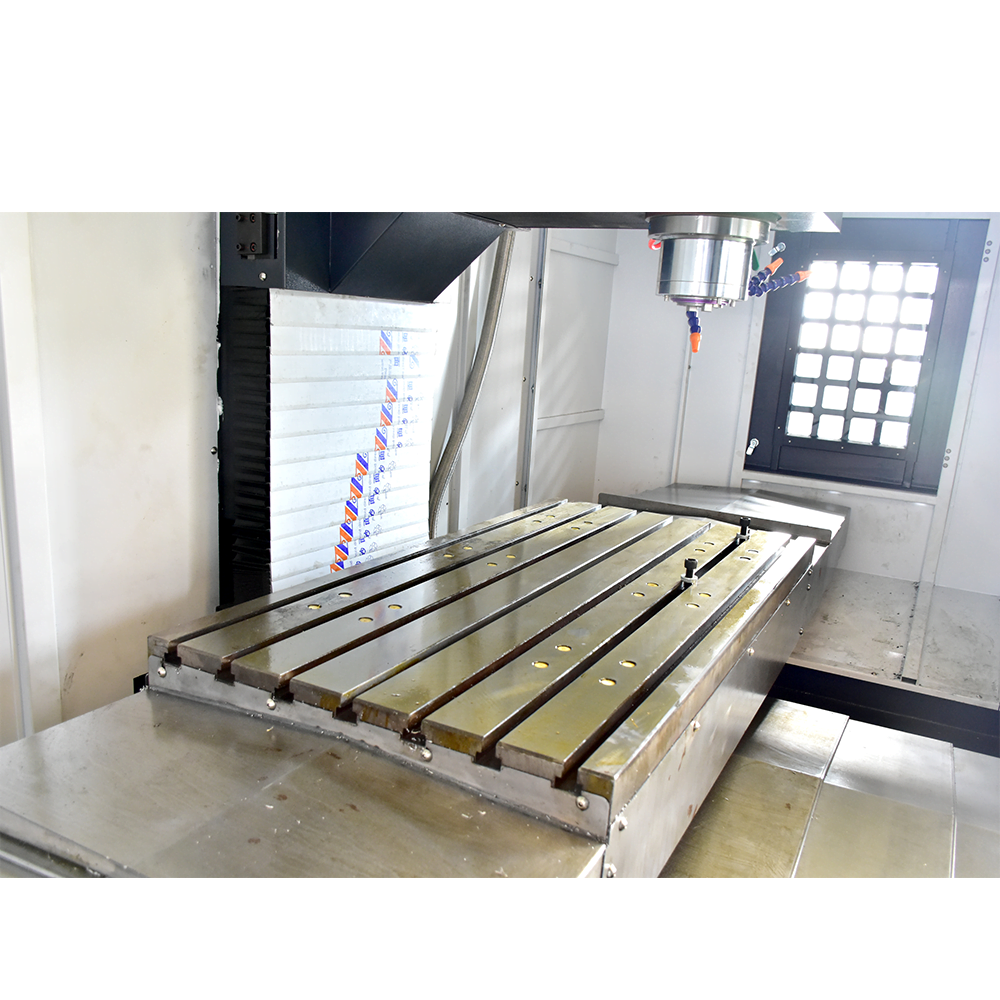

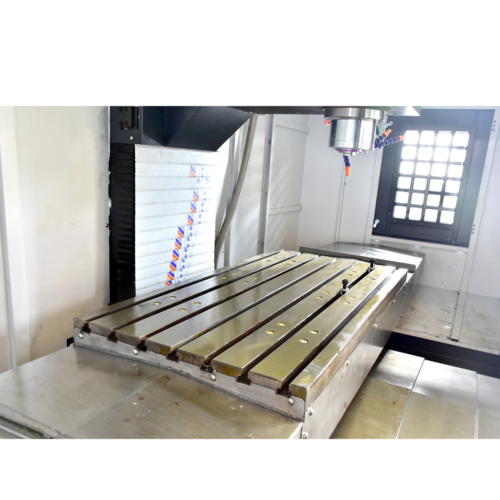

| Table size | mm | 1300×700 |

| X axis travel | mm | 1200 |

| Y axis travel | mm | 700 |

| Z axis travel | mm | 600 |

| Max. worktable load | kg | 1200 |

| T slot(number-width-pitch) | 5-18×125 | |

| Max. spindle speed | rpm | 8000(Optional:10000 ) |

| Spindle taper | mm | BT50/BT40 |

| Main motor power | kw | 11/15 |

| X/Y/Z rapid traverse speed | m/min | 24/24/12 |

| Cutting feed speed | mm/min | 1-5000 |

| Guide rail type | Linear rail | |

| Distance from spindle axis to column surface | mm | 780 |

| Distance between spindle nose and worktable surface | mm | 140-700 |

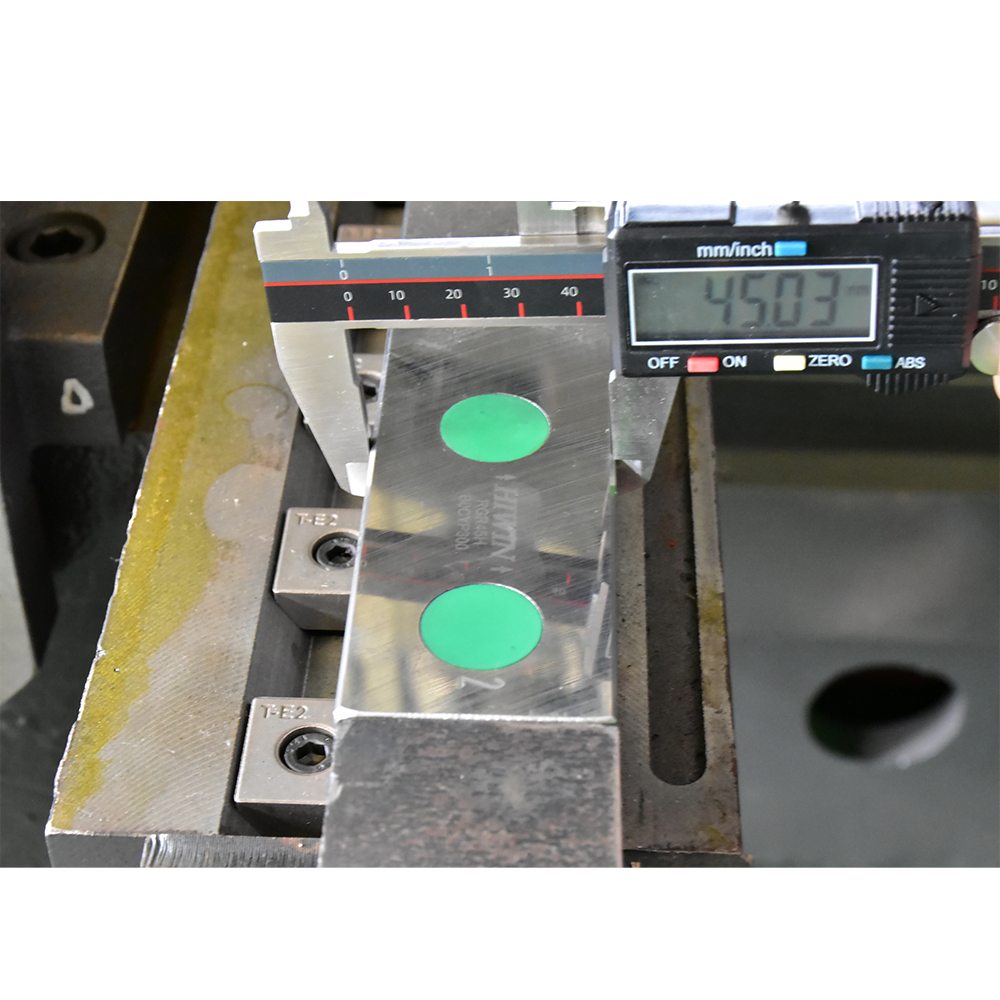

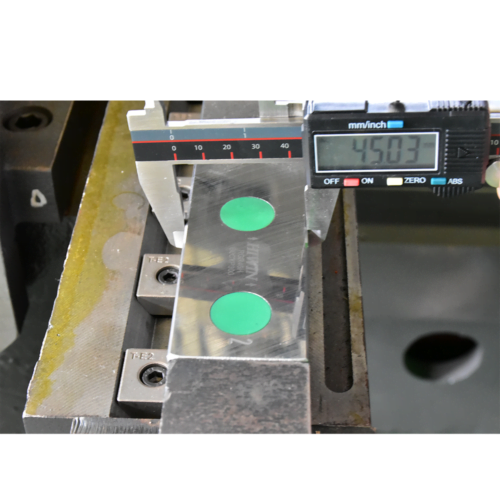

| Positioning accuracy | mm | ±0.0075 |

| Repeat positioning accuracy | mm | ±0.005 |

| Tool magazine | Arm 24 | |

| Max. tool diameter | mm | φ112 (Adjacent)/ φ200(Apart) |

| Max.tool weight | kg | 18 |

| Machine weight | kg | 9500 |

| Overall dimension | mm | 3400x2480x2960 |

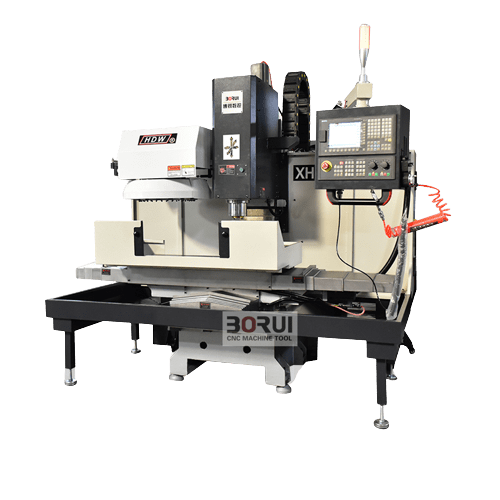

Advantages of VMC1270 5 Axis Vertical Machining Center

It is Resin sand casting and honeycomb structure. After multiple stress elimination processes, the new herringbone column structure is an M-shaped reinforcement.

- Double layer worktable structure can improve the rigidity and stability of machine tools.

- Combined with surface scraping to ensure lasting accuracy and stability. It can prolong the service life of the machine.

- Import a high-speed spindle protection structure with a beautiful atmosphere.

- High-precision P roller wire gauge. It ensures the machine is high speed, cutting kinetic rigidity and accuracy requirements.

- Reasonable structure design of machine tool. It has high rigidity and high stability.

- High-quality parts selection, machine tool thermal change small, high precision. A unique shield protection design can ensure the machine’s life.

- Six sliding block structures significantly increase the load capacity. It enhances the rigidity, accuracy, and durability of the machine.

.png)

-500x500.png)

Reviews

There are no reviews yet.