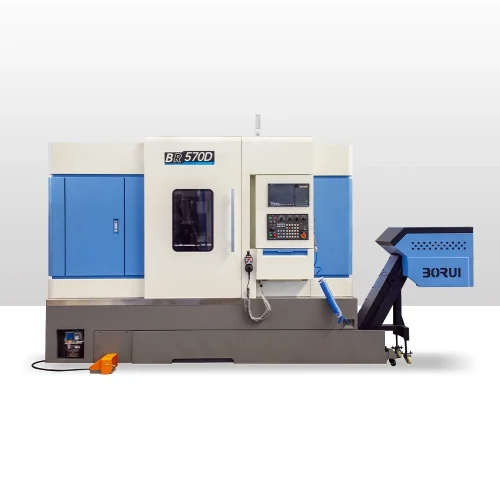

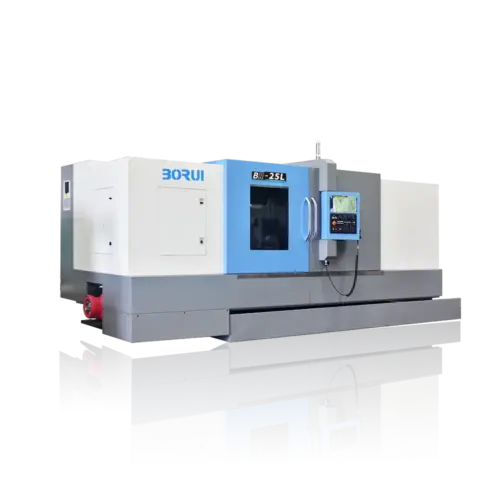

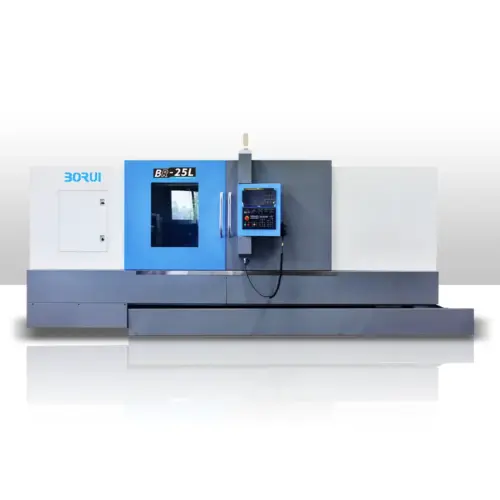

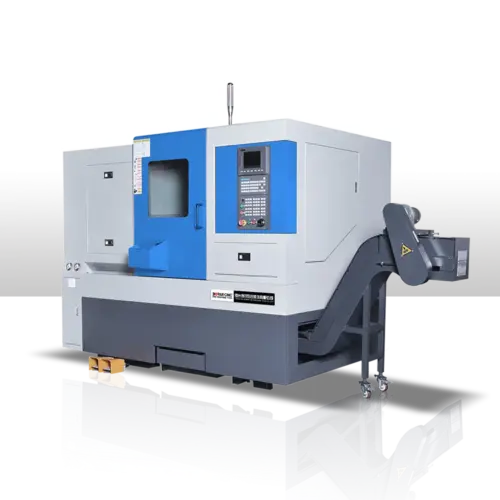

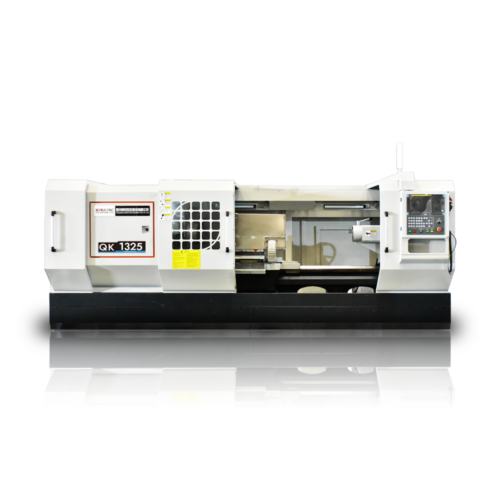

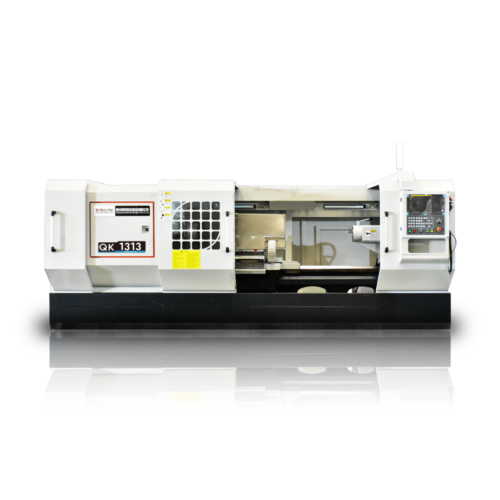

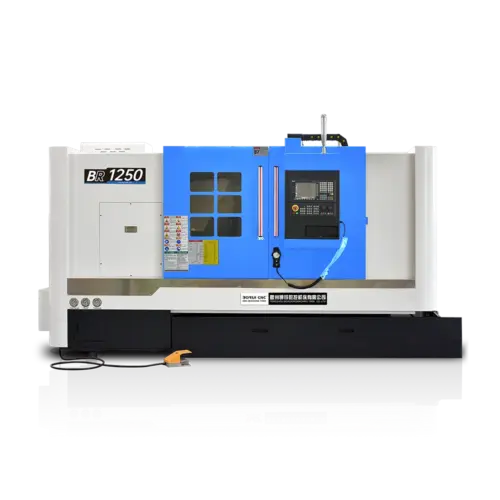

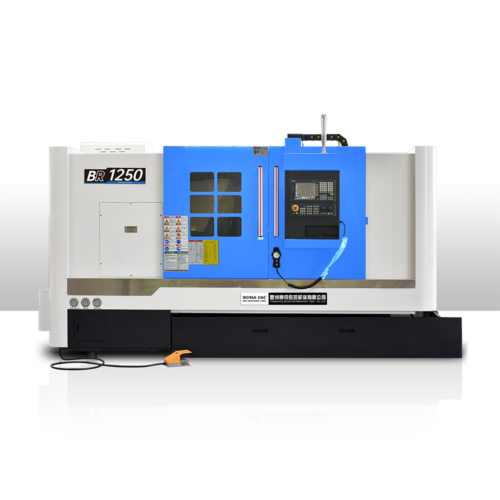

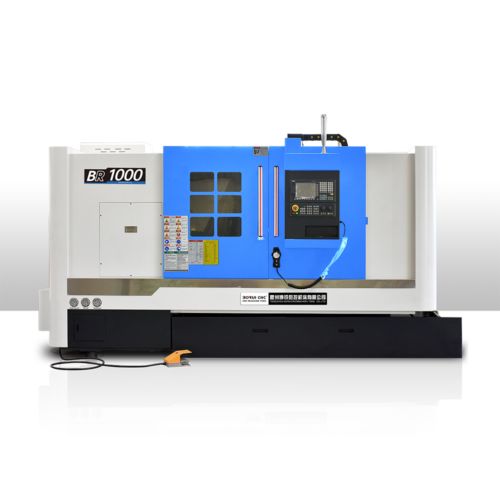

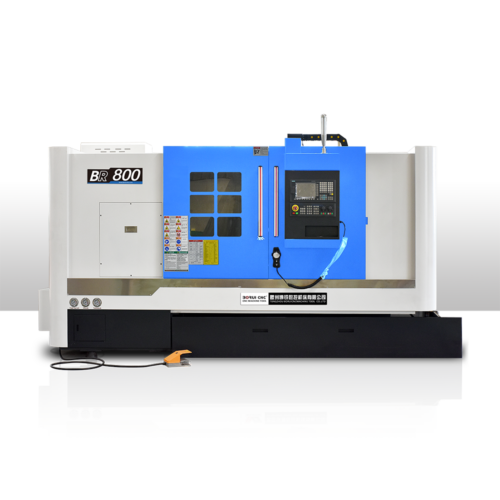

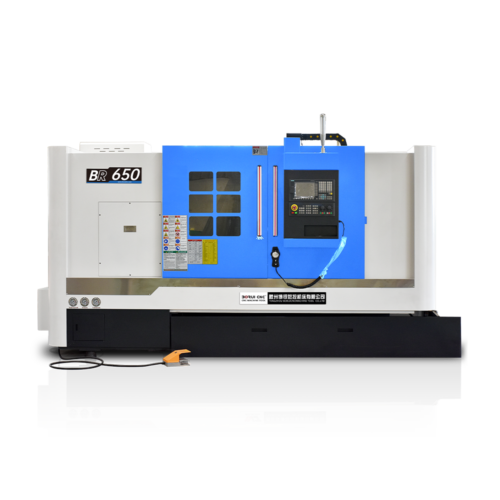

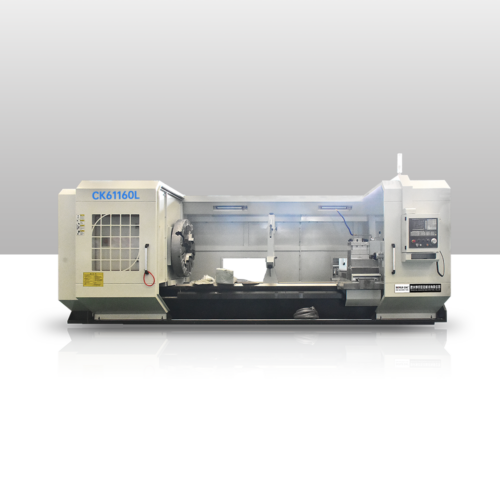

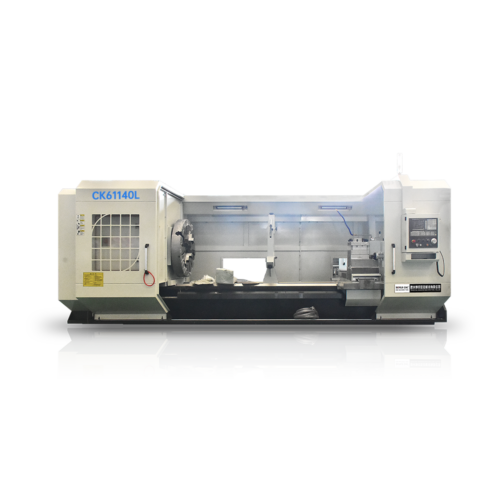

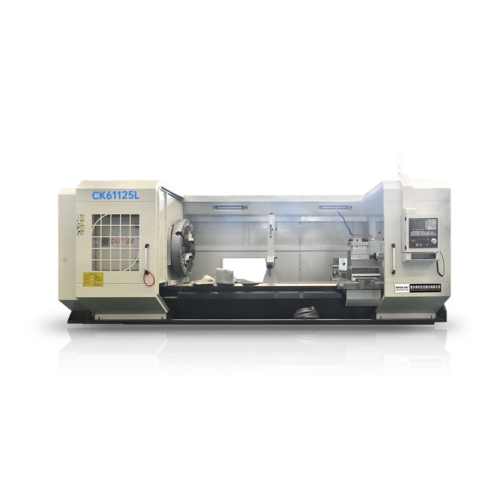

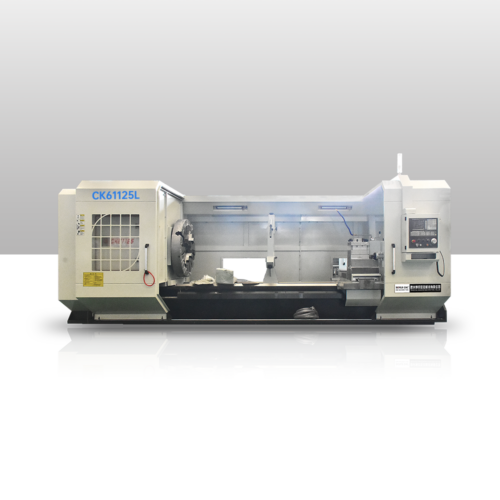

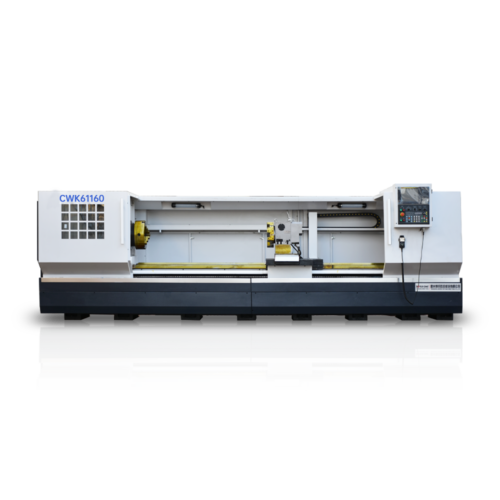

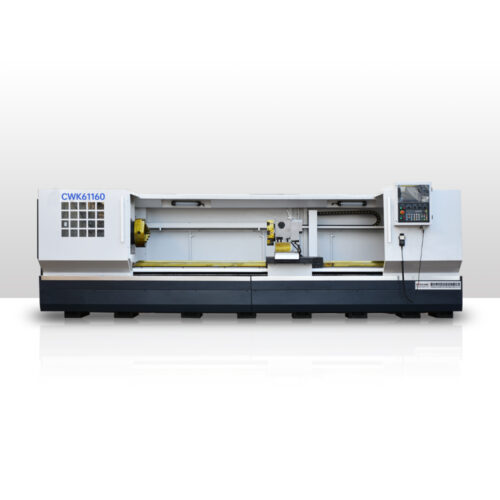

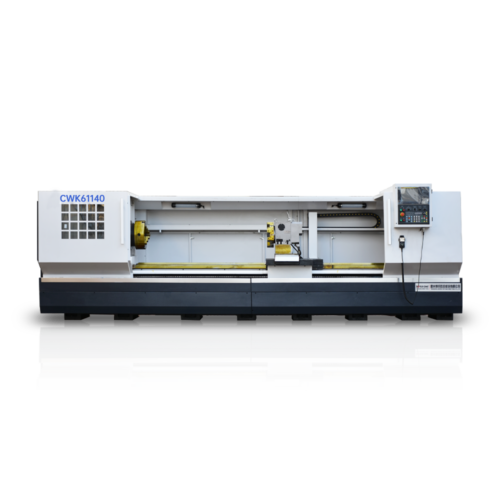

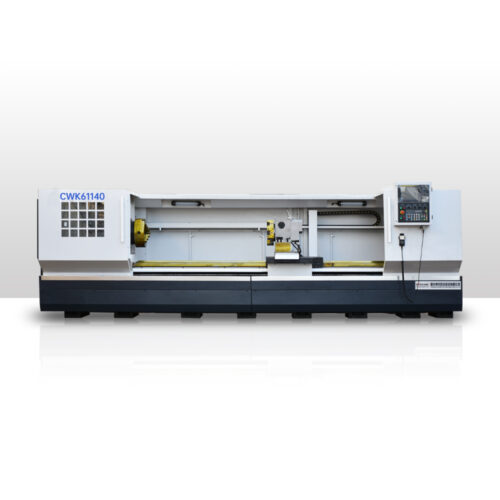

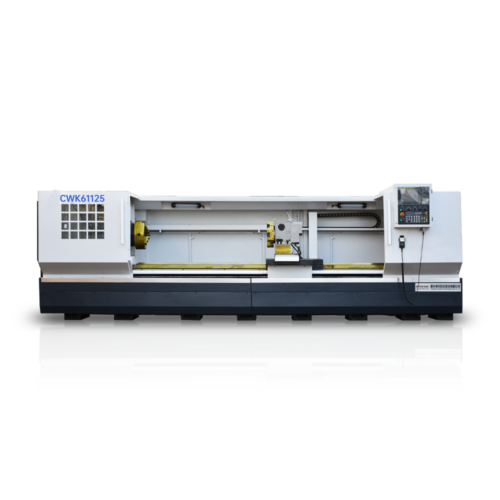

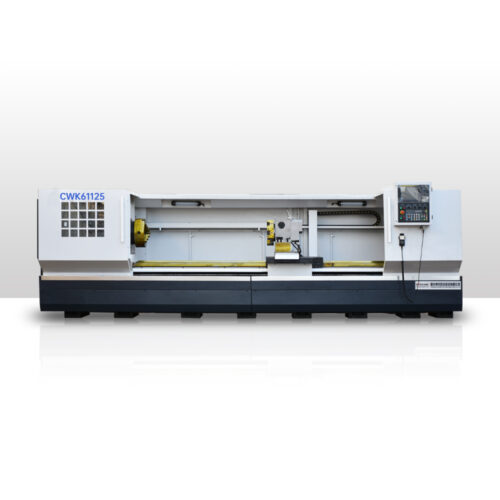

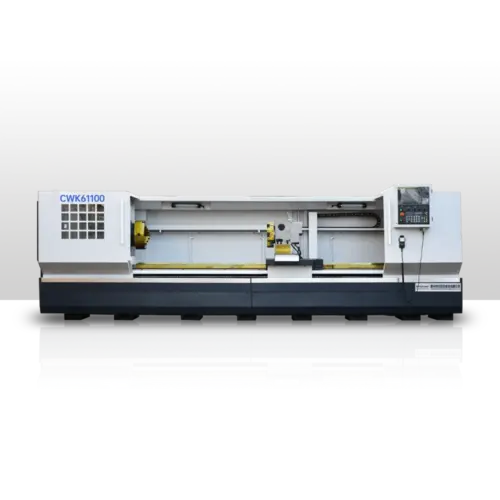

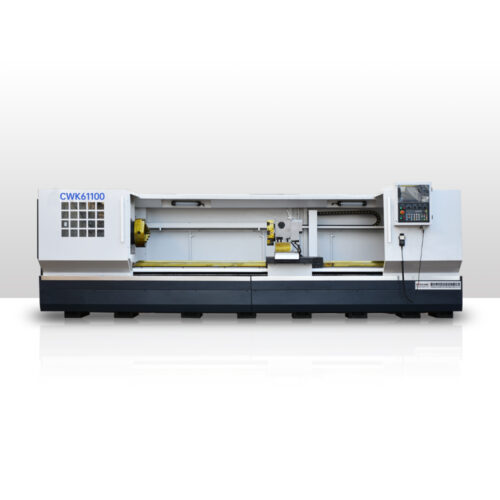

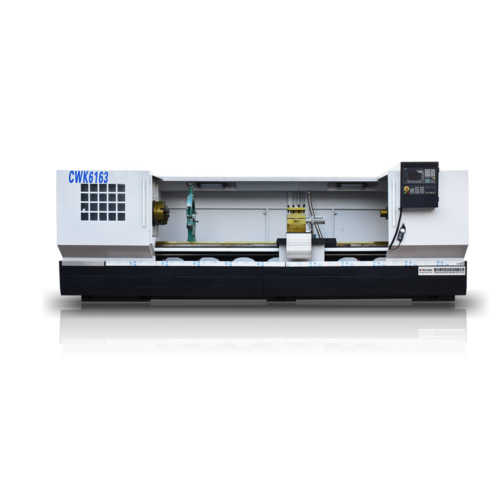

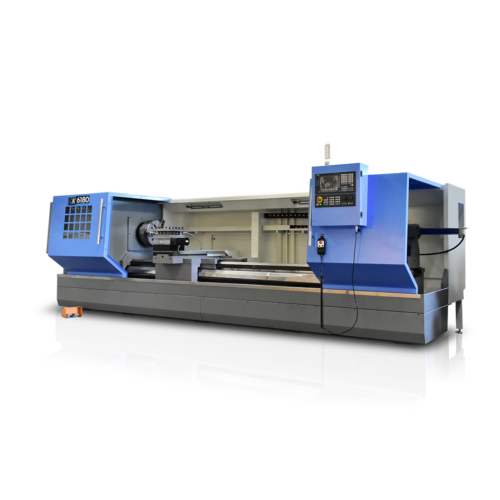

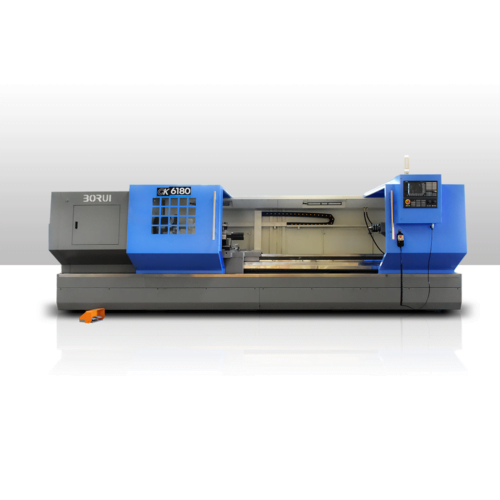

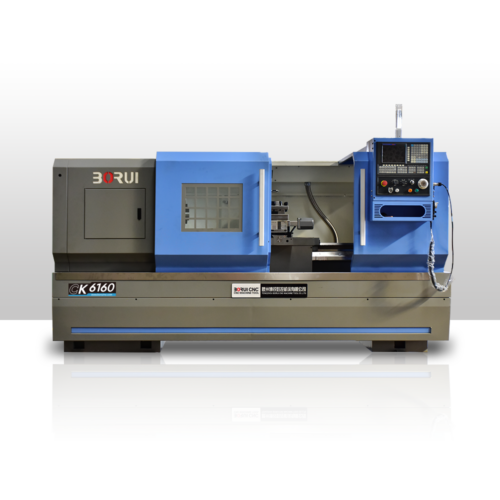

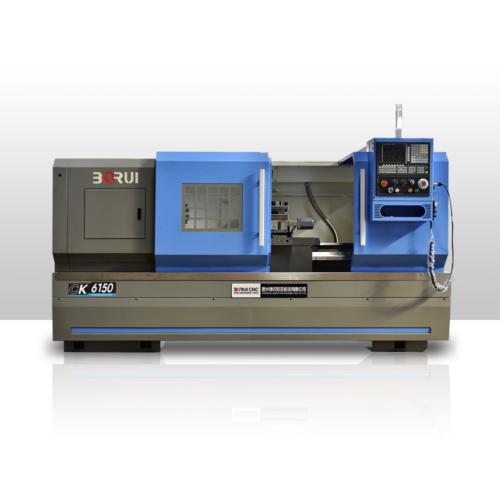

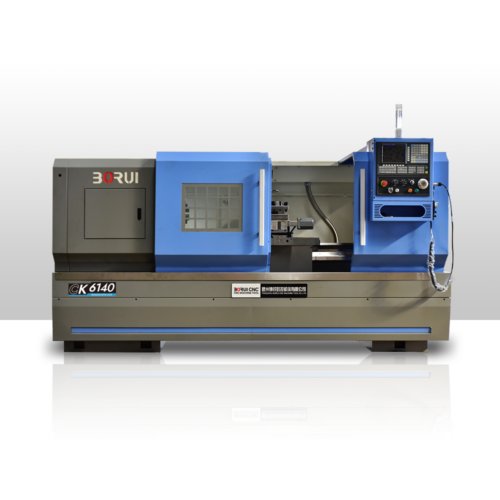

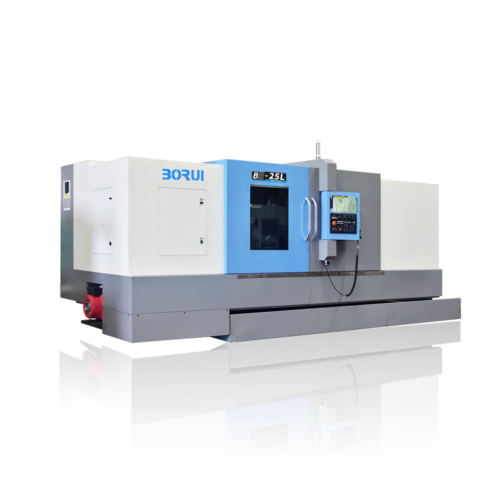

CNC Lathe Machine Manufacturer

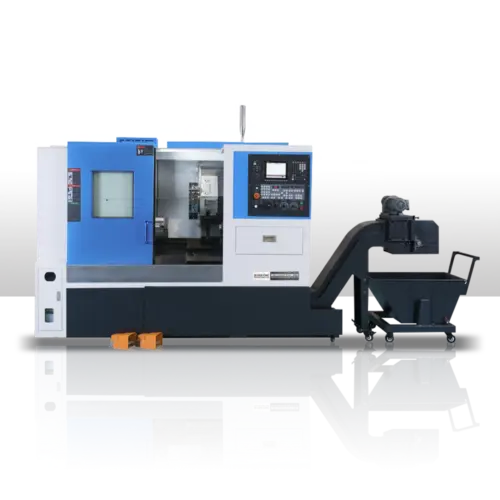

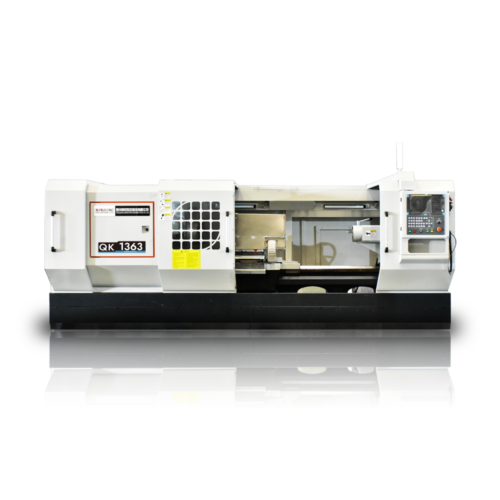

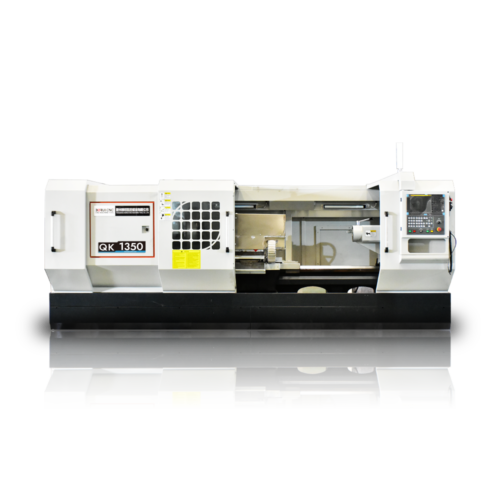

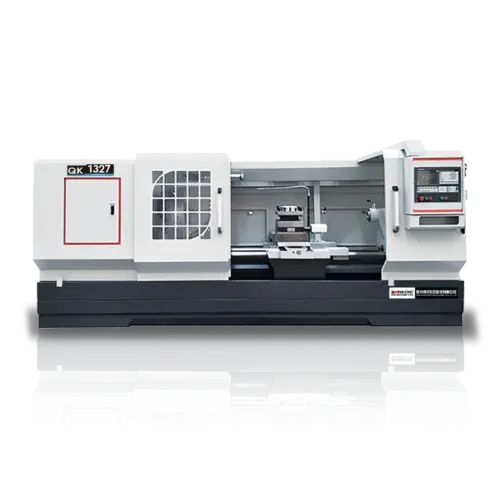

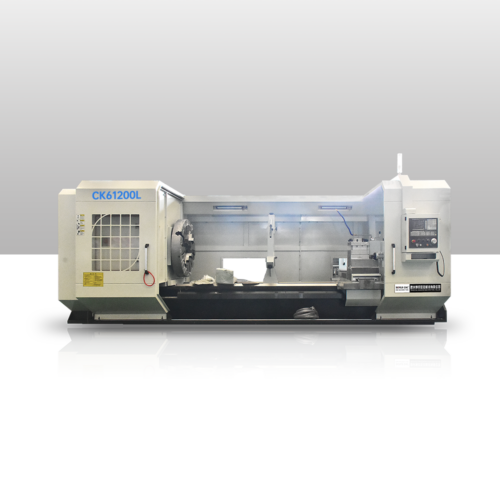

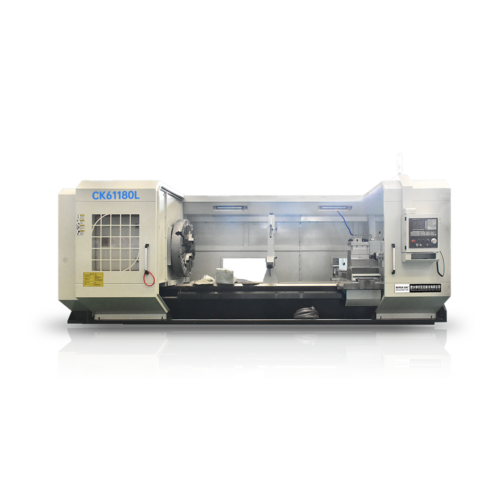

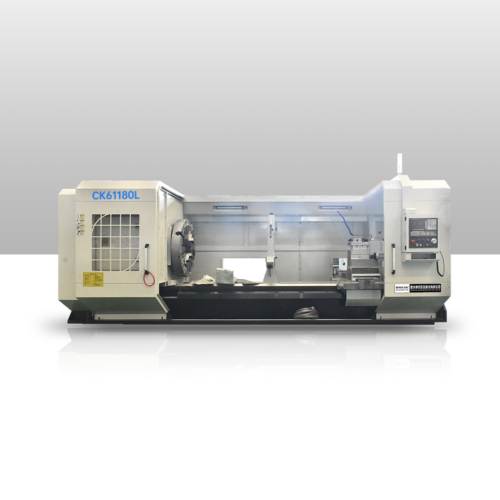

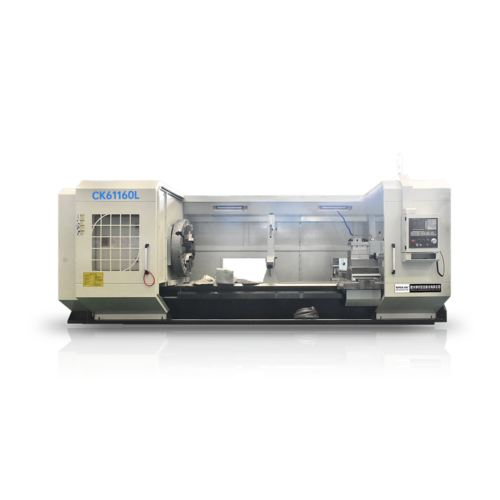

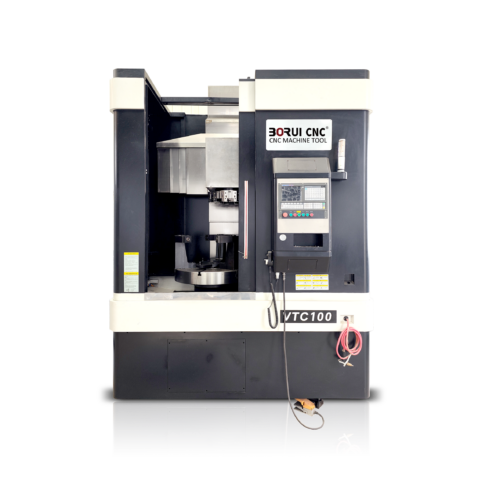

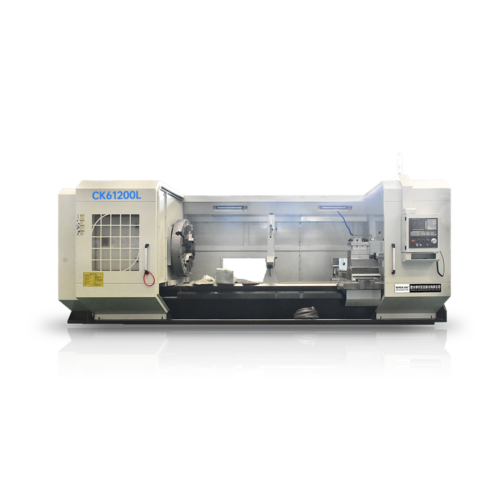

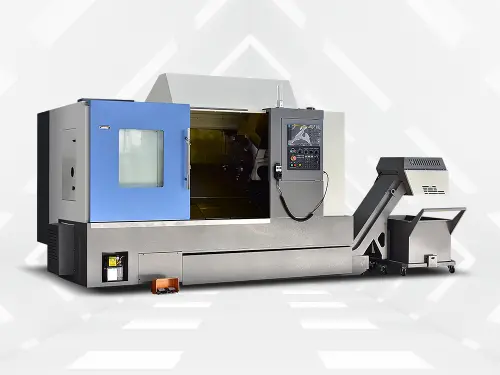

Borui is a professional CNC lathe manufacturer in China. We provide different types of high-precision and high-efficiency CNC lathes, such as CNC vertical lathes, flat CNC lathes, CNC pipe threading lathes, slant bed CNC lathes, with competitive prices and professional services.

We have invested a lot of money in research and development. This is to keep our machines at the forefront. BORUI prides itself on excellent quality. We use strict quality processes and certifications. They ensure that each lathe CNC machine meets high standards.

Our goal is to provide customers with reliable tools. These tools can help them carry out production smoothly. Welcome to contact us for more information about CNC lathes.

Request a Quote!Why Choose BORUI As Your CNC Lathe Supplier

Technology Leadership

BORUI has always maintained technological leadership in the field of CNC lathes. We continuously invest in research and development and introduce the latest CNC technology and intelligent design. It can ensure our products are always in a leading position in the market.

High-precision Processing

As one of the most professional CNC lathe manufacturers, our lathe CNC machines adopt the most advanced CNC system. We can promise high-precision machining. Each piece of equipment undergoes strict quality control. So we can meet customers' stringent requirements for accuracy.

Excellent Stability And Reliability

BORUI's lathe CNC machines are designed and manufactured with meticulous engineering. They have superior stability and reliability. It ensures the strength of the equipment during long-term operation and reduces the failure rate of the production line.

Customized Solutions

BORUI understands that each customer's production needs are unique. That's why we offer customized solutions. Whether it's a small factory or an extensive production line, we can provide CNC lathes to meet your specific needs.

Applications of CNC Lathe Machine

CNC lathe machines are widely used in multiple industrial fields, providing efficient and precise processing solutions for various industries:

Automobile Manufacturing

CNC lathes are widely used for precision processing of key parts such as automobile engines, transmissions, brake systems, etc., ensuring the high quality and high precision of each part.

Aerospace

In the aerospace field, CNC lathes are used to manufacture aircraft parts and aerospace equipment components, meeting extremely high precision and quality requirements to ensure the safety and performance of aircraft.

Medical Equipment

CNC lathes provide precision parts processing for the medical equipment industry, such as surgical instruments, implants and diagnostic equipment, ensuring product reliability and accuracy.

Mold Processing

The CNC lathes we provide can efficiently process various molds and are widely used in the manufacture of plastic, metal and rubber molds, improving production efficiency and mold life.

CNC Lathes Buying Guide

What is A CNC Lathe Machine?

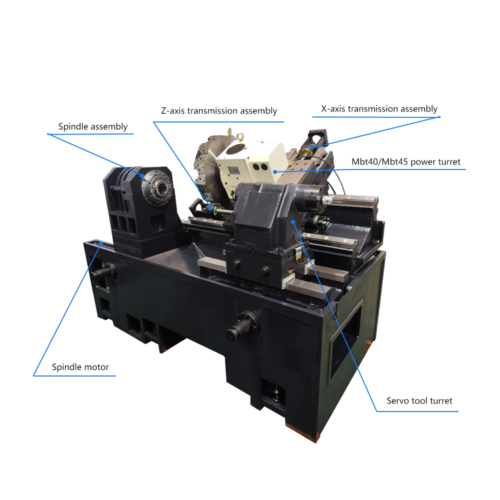

CNC lathe is a machine tool mainly used for turning and processing rotating workpieces with turning tools. CNC lathe is a computer digital control lathe. It is a high-precision and high-efficiency automatic machine tool. It has a wide range of machining functions. The CNC lathes can process linear cylinders, sloping cylinders, circular arcs, and threads.

How Many Types of CNC Lathes Are There?

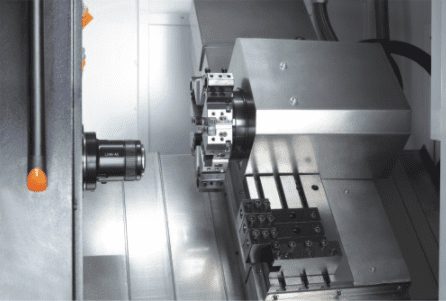

CNC lathe and turning center are exact and efficient automatic machine tools. Equipped with a multi-station turret or power turret, the machine tool performs a wide range of machining processes. It can process linear cylindrical, diagonal cylindrical, circular arcs, threads, slots, worm gears, and other complex workpieces. It has linear interpolation, circular arc interpolation, and various compensation functions. The CNC lathes played a good economic role in the mass production of complex parts.

There are many varieties and different specifications of CNC lathes. They are generally classified as follows.

CNC lathe classification – according to the function of the CNC system

1) Full-function CNC Lathe

This lathe has a high resolution and fast feeding speed (generally more than 15m/min). Most feeding adopts a semi-closed-loop DC or AC servo system, and the machine accuracy is relatively high with a CRT display. It not only characters but also graphics, man-machine dialogue, self-diagnosis, and other functions.

2) Economic CNC Lathe

The structure and layout of most economical CNC lathes are similar to ordinary lathes. Generally, it adopts an open-loop servo system driven by a stepper motor and single-board or single-chip computer to realize the control function. The display mainly adopts a digital tube or simple CRT character display.

3) CNC Turning Center

The turning center is a full-featured CNC lathe as the main body. It configured the tool magazine, tool changer, indexing device, milling power head, and robot. After one clamping, it can complete a variety of machining processes. Such as turning, milling, drilling, reaming, and tapping threads of rotary parts. Its function is comprehensive, but the price is high.

4) FMC Lathe Machine

FMC lathe machine is a flexible processing unit composed of a CNC lathe, robot. It can realize the automation of workpiece handling, loading and unloading, and processing adjustment preparation.

CNC lathe classification – according to the configuration form of the spindle axis

1) Horizontal CNC Lathe Machine

The CNC lathe whose central axis is in a horizontal direction is called a horizontal CNC lathe.

2)Vertical CNC Lathe Machine

The CNC lathe whose spindle axis is in the vertical direction is called a CNC vertical lathe. The CNC lathe with two spindles is called a two-axis CNC horizontal lathe or CNC vertical lathe.

CNC lathe classification – according to the type of processed parts

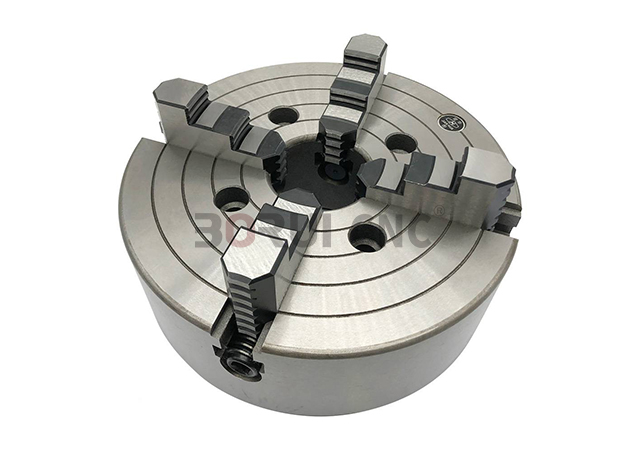

1) chuck type CNC machine tools

This lathe type does not set tailstock, which is suitable for turning disc parts. Its clamping method is electric, primarily motor or hydraulic control. Most of the chuck structure has jaws.

2) Item tip type CNC lathe

These lathes are equipped with common tailstock or CNC tailstock. They are suitable for turning more extended shafts, smaller large-diameter discs, and sleeve parts.

Classification of CNC lathe–According to the number of axes controlled by the CNC system

1) 2 axis control CNC lathe

The machine has only one rotary tool holder, which can realize the control of two axes.

2)4 axis control CNC lathe

The machine tool has two independent rotary tool holders, which can realize the control of four coordinate axes.

Other classification

According to the different control methods of the CNC system and other indicators. CNC lathes can be divided into linear and contour control CNC lathes. Technical exceptional or specialized process performance can be divided into thread CNC lathe, piston CNC lathe, and crankshaft CNC lathe. Also, a new type of foreign CNC lathe can turn quenched parts, called hard turning CNC lathe. Turning no quenched parts of the lathe is called soft turning CNC lathe.

FAQs About Lathe CNC Machines

Traditional lathes are typically manually operated by an operator. CNC lathes, on the other hand, perform operations automatically through a pre-programmed computer program. This enables lathe CNC machines to achieve higher precision and production efficiency.

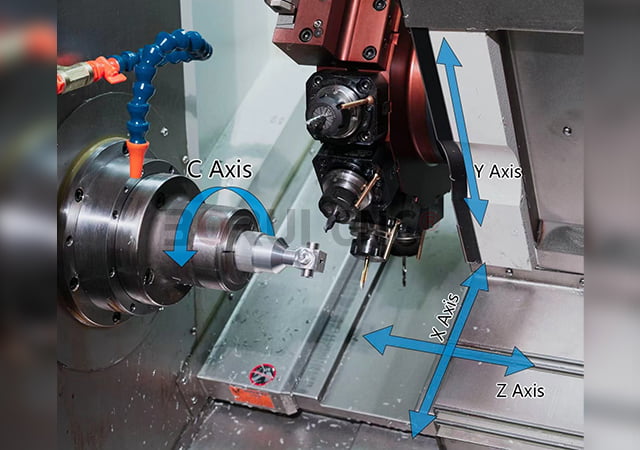

CNC lathes cut and shape workpieces by reading codes generated by a computer to control the movement and rotation of the tool. The program defines parameters such as the tool's path, speed, and depth of cut.

CNC lathes can be used to machine a variety of materials. Includes metal, plastic, wood, and composite materials. Selecting the appropriate tool and cutting parameters depends on the material's properties.

Maintenance requirements include regular lubrication, tool replacement, and inspection of electrical systems and transmission systems. Specific maintenance schedules are usually provided by the manufacturer.