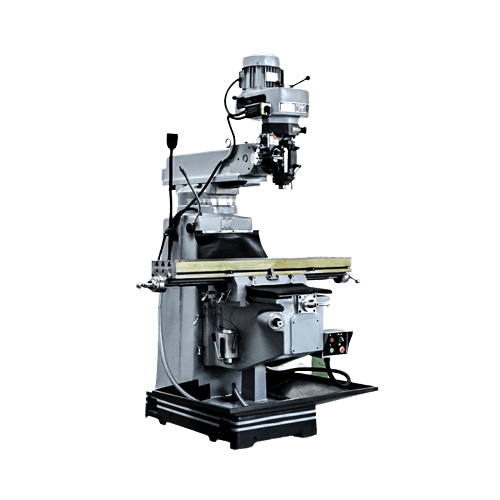

Vertical Milling Machine

BORUI is a vertical milling machine manufacturer with many years of experience. Our products use innovative technology and craftsmanship. As a professional manufacturer, BORUI pays attention to product quality. We can guarantee product performance and processing efficiency. If you have more detailed questions about BORUI, it is recommended that you contact our customer service team directly. They will give you the most complex answers.

Request a Quote!Features of BORUI Vertical Milling Machine

Cutting in Vertical Direction

The spindle of a vertical milling machine points downwards. The relative motion of the tool and workpiece occurs in the vertical direction. This layout is suitable for processing three-dimensional parts and vertical cutting operations.

Multi-axis Control

Many vertical milling machines are equipped with CNC systems. It allows multi-axis control in different directions. It enables more complex cutting tasks.

Surface Milling

Vertical milling machines are commonly used for surface milling. A flat surface can be produced by horizontal movement of the tool over the workpiece surface.

Adjustable Cutting Speed

The vertical mill machine can select appropriate cutting speeds for different processing needs and materials. It can achieve the best cutting results.

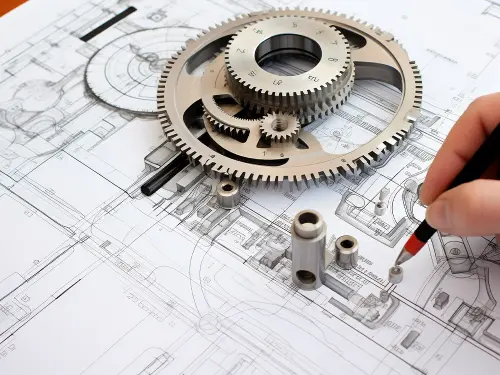

Vertical Mill Machine Applications

Vertical milling machines are widely used in manufacturing industries. It can complete a variety of cutting, milling, and drilling tasks. Here are some of the main applications of vertical milling machines.

Why Choose Us As Your Vertical Milling Machine Manufacturer

Product Series

BORUI can provide customers with many series of vertical milling machines. Customers will have different needs. We can meet the needs of various industries and customers.

High Quality Standard

As a professional horizontal milling machine manufacturer, BORUI pays great attention to product quality. We have advanced manufacturing technology and a quality control system. We can ensure the high quality of the products.

Innovative Technology

BORUI's vertical mill machines adopt innovative technology and processes. They can improve product performance and processing efficiency.

Customer Service

BORUI provides comprehensive customer service to customers worldwide. These include pre-sales consultation, customized solutions, after-sales service, etc.

FAQs About Vertical Mill Machines

The relative movement of the tool and workpiece of a vertical milling machine is performed in a vertical plane. A horizontal milling machine, on the other hand, works in a horizontal plane. Vertical milling machines are usually used for cutting three-dimensional parts.

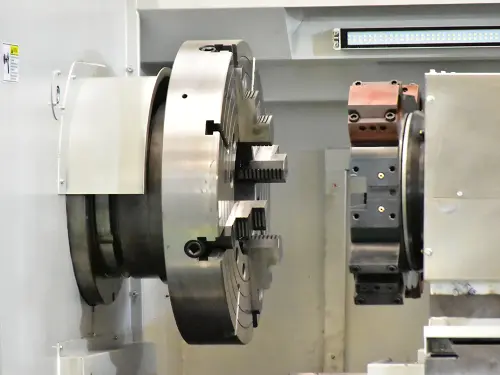

The main components include lathe, spindle, workbench, feed mechanism, tool and tool holder, CNC system, etc.

The advantages of vertical milling machines include suitability for processing three-dimensional parts, multi-axis control, high precision, CNC programming, and adaptability to a variety of cutting tasks.