Product Video Display

Technical Parameters Of Vertical Elevating Table Milling Machine X5032A

| SPECIFICATIONS | Units | X5032 | X5032B | X5032BH | X5040 |

|---|---|---|---|---|---|

| Table size | mm | 1325*320 | 1600*320 | 1600*320 | 1700*400 |

| Table load | kg | 500 | 500 | 500 | 800 |

| T slot(number -width*pitch) | 3-18*70 | 3-18*70 | 3-18*70 | 3-18*90 | |

| Table travel (manual/auto) | mm | 700/680 255/240 370/350 | 900/880 255/240 370/350 | 900/880 255/240 460/440 | 900/880 315/880 385/365 |

| Table feed range | mm/min | XY:23.5-1180 Z:8-394 | XY:23.5-1180 Z:8-394 | XY:23.5-1180 Z:8-394 | XY:23.5-1180 Z:8-394 |

| Table rapid traverse | mm/min | XY:2300 Z:770 | XY:2300 Z:770 | XY:2300 Z:770 | XY:2300 Z:770 |

| Spindle taper | ISO50 7:24 | ISO50 7:24 | ISO50 7:24 | ISO50 7:24 | |

| Spindle speed range(steps) | rpm | 30-1500(18) | 30-1500(18) | 30-1500(18) | 30-1500(18) |

| Swivel angle of vertical milling head | ° | ±45 | ±45 | ±45 | ±45 |

| Distance between spindlenose and table surface | mm | 45-415 | 45-415 | 45-490 | 130-515 |

| Main motor power | kw | 7.5 | 7.5 | 7.5 | 11 |

| Feed motor power | kw | 1.5 | 1.5 | 1.5 | 1.5 |

| Machine weight | kg | 2900/3200 | 3000/3300 | 3100/3400 | 4250/4500 |

| Overall dimension | mm | 2300*1770*2000 | 2300*1770*2000 | 2600*1770*2200 | 2560*2160*2300 |

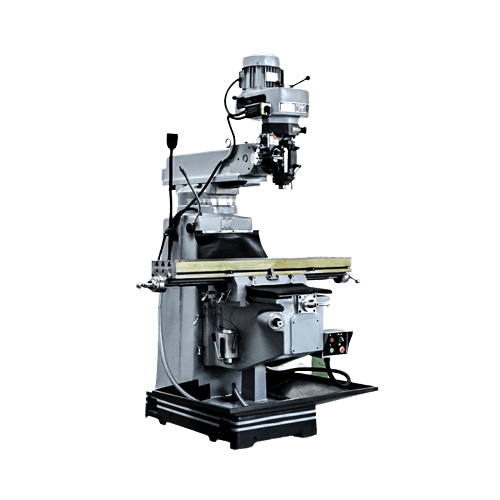

Features Of X5032A Elevating Table Manual Vertical Milling Machine

- The main components, such as the base, body, worktable, middle slide, lift slide, and spindle box, are all cast with high-strength materials. They are processed by artificial aging. It can ensure the long-term stability of the vertical manual milling machine.

- The milling head of the X5032 vertical milling machine can be adjusted by ±45° in the vertical plane and reverse rotation. It can expand the processing range of the machine tool. The main shaft bearing is a tapered roller bearing with a strong bearing capacity. The main shaft adopts energy-consumption braking, ample torque, and a quick and reliable stop.

- The worktable has three types of X/Y/Z directions: manual feed, motorized feed, and fast-forward. The feed speed can meet different processing requirements. Fast-feed can make the workpiece quickly reach the processing position. It is convenient and fast for processing, shortening the non-processing time.

- The X, Y, and Z three-direction guide rail pairs are quenched by ultrasonic frequency and precision ground and scraped and cooperated with forced lubrication. It can improve the accuracy and prolong the service life of the machine tool.

- The lubrication device can forcibly lubricate the vertical, horizontal, and vertical screw and guide rails. It can reduce the wear of the machine tool and ensure the efficient operation of the X5032 vertical lift table milling machine. At the same time, the cooling system changes the coolant flow rate by adjusting the nozzle. Size can meet different processing needs.

- The machine tool design conforms to ergonomic principles and is easy to operate. The operation panels are designed with visual symbols, which are simple and intuitive.

Product Image Display

HORIZONTAL MILLING

Spindle taper 7: 24 ISo50

Spindle speed: 60-1800(12steps)

BOOM TYPE OPERATION BOX

Independent button operation box, easy to use.

X Y AXIS AUTO FEED

Z axis electric lifting

improve processing time.

MAUNAL LUBRICATION

Manual lubrication is used to prolong the service life of the machine.

PURE COPPER MOTOR

Pure copper motor is adopted, with long service life.

Reviews

There are no reviews yet.