With the continuous development of science and technology, CNC lathes play an important role in modern manufacturing industry. As an important part of CNC lathe, Y-axis has an important influence on its performance and function. This paper will discuss the benefits of Y-axis to CNC lathes, including improving machining accuracy, increasing machining range, improving production efficiency and so on.

Adding a Y motion axis can use more tools in cutting equipment to master more complex cutting processes and complete the cutting of more complex parts.

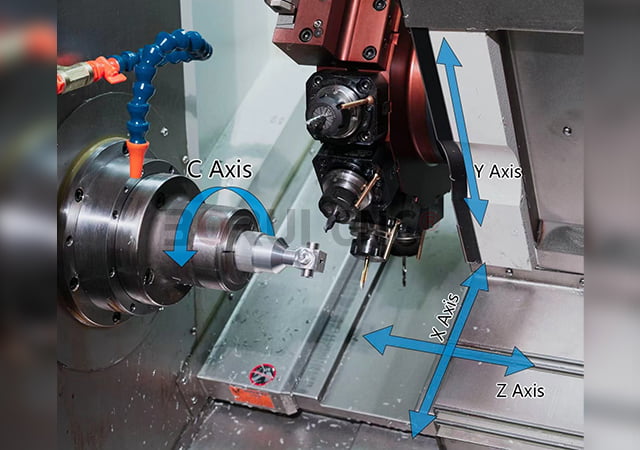

CNC lathe is a machine tool controlled by computer, which can automatically process the workpiece and monitor the processing process. The main components of CNC lathes include bed, spindle, servo system and various axial moving systems. Among them, the Y-axis is an important part of the CNC lathe, which is responsible for the movement of the workpiece in the longitudinal direction. The performance and function of Y-axis have an important impact on the machining accuracy, processing range and production efficiency of CNC lathes. This paper will discuss the influence of Y-axis on CNC lathes in detail.

The precise control of the Y-axis enables CNC lathes to achieve higher accuracy in the machining process. By moving the Y-axis, the workpiece can be adjusted slightly in the longitudinal direction, making the machining process more fine and accurate. In addition, the precise control of the Y-axis can also reduce the scrap rate caused by machining errors and improve production efficiency.

The presence of the Y-axis allows CNC lathes to carry out a wider range of machining in the longitudinal direction. By adjusting the position of the Y-axis, CNC lathes can process longer and higher workpieces. In this way, the processing range of CNC lathes has been expanded to meet the processing needs of more different sizes of workpieces.

The rapid movement of the Y-axis can greatly improve the production efficiency of CNC lathes. Compared with traditional machine tools, CNC lathes can achieve faster workpiece movement and processing speed through the precise control of the Y-axis. This not only improves production efficiency, but also shortens the processing cycle, making the production process more efficient and flexible.

The existence of the Y-axis allows CNC lathes to achieve a more diverse range of machining functions. Through the control of Y axis, CNC lathes can realize the machining of special shapes such as tilt machining and curve machining at different angles. In this way, the application field of CNC lathes has been further expanded, and can meet the processing needs of more different shapes of workpieces.

As an important part of CNC lathe, Y-axis has an important influence on its performance and function. Through the precise control of the Y-axis, CNC lathes can improve the machining accuracy, increase the processing range, improve production efficiency, and realize multi-functional machining. Therefore, the role of Y-axis on CNC lathes can not be ignored, and it is of great significance for the development of modern manufacturing industry.

https://www.youtube.com/watch?v=eX7QvnV1aBQ

Request Quotation