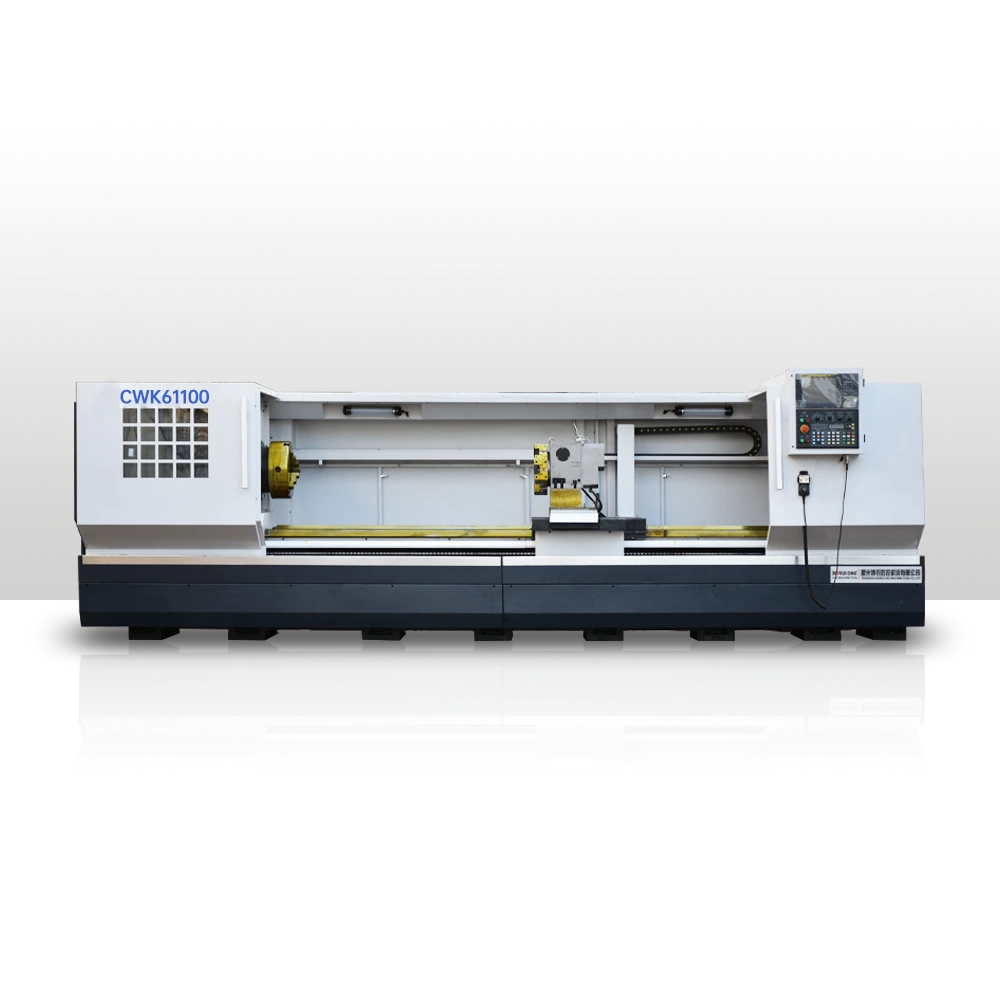

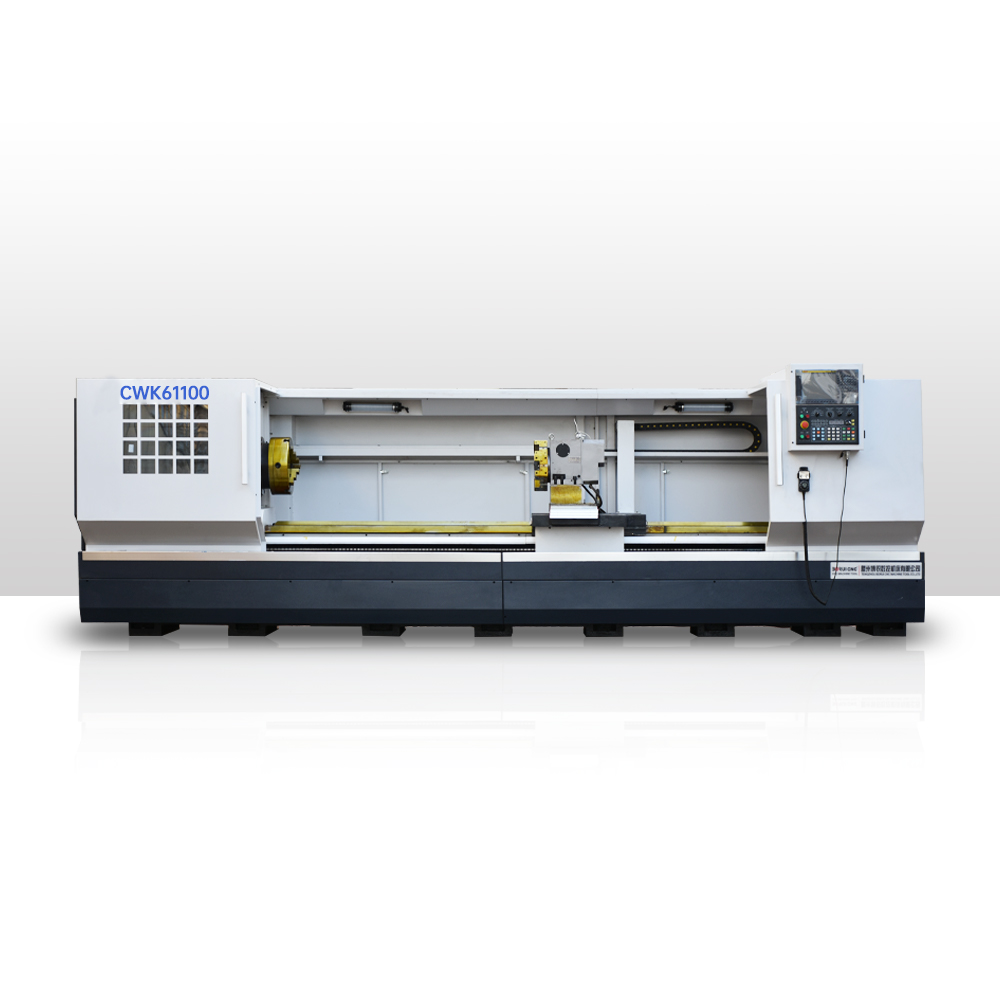

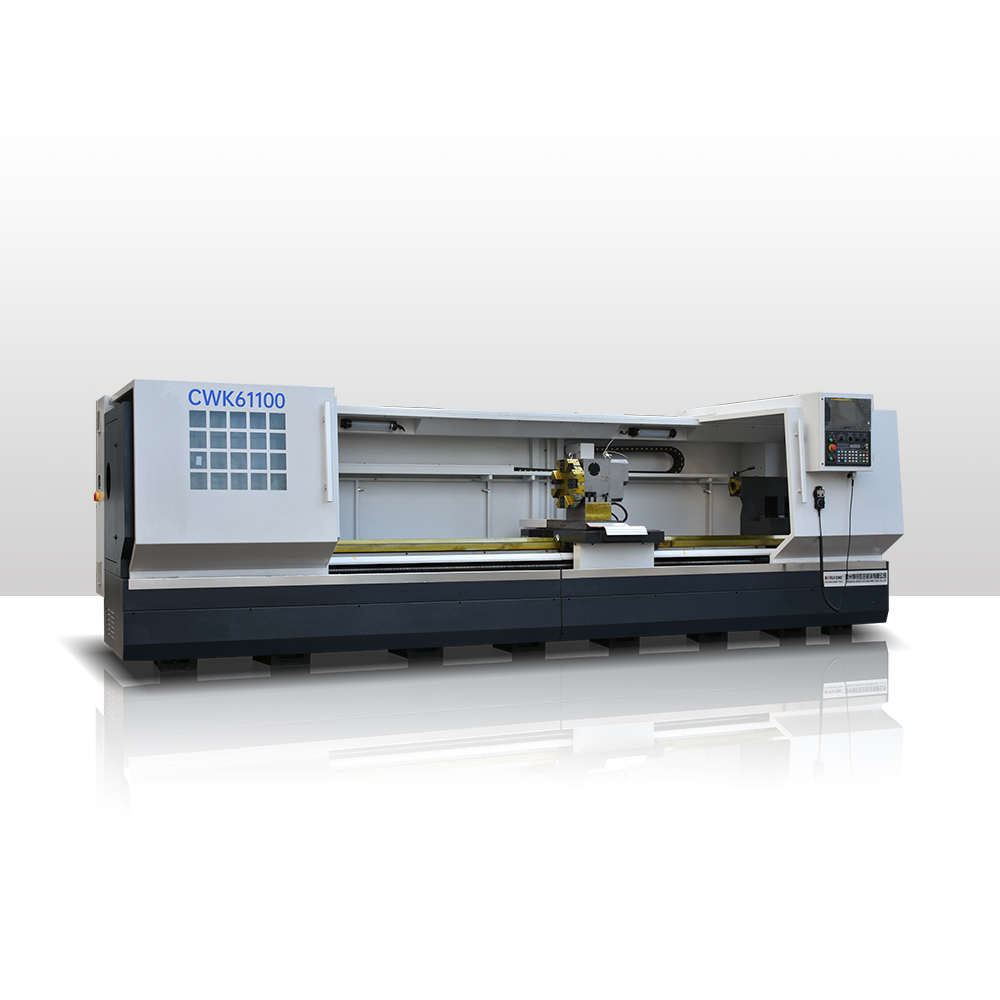

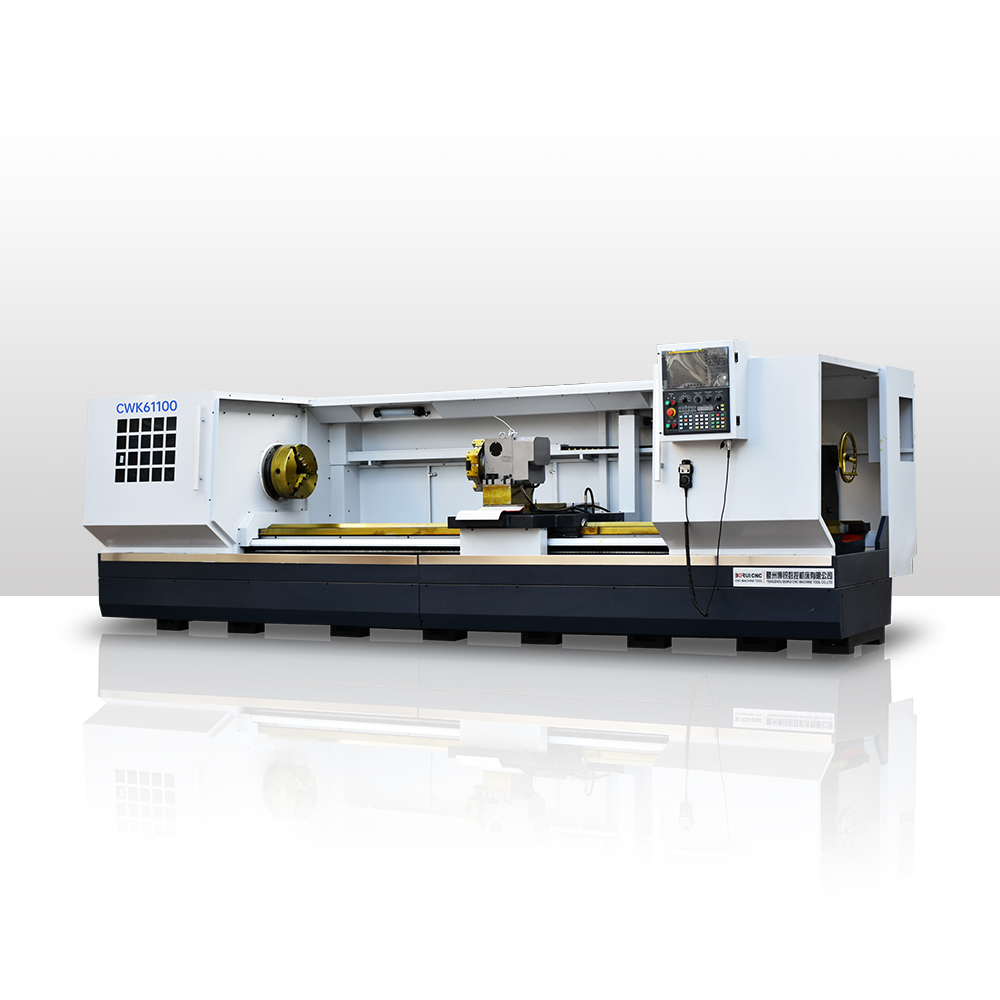

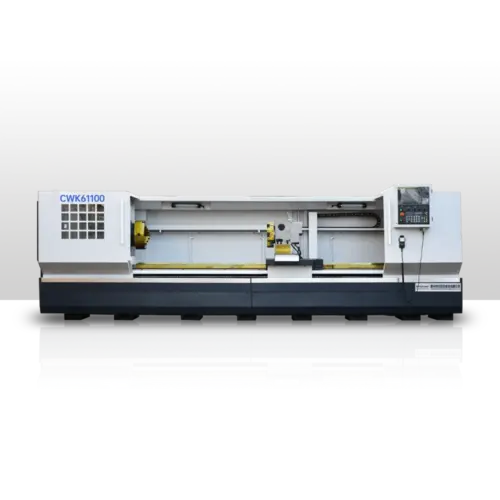

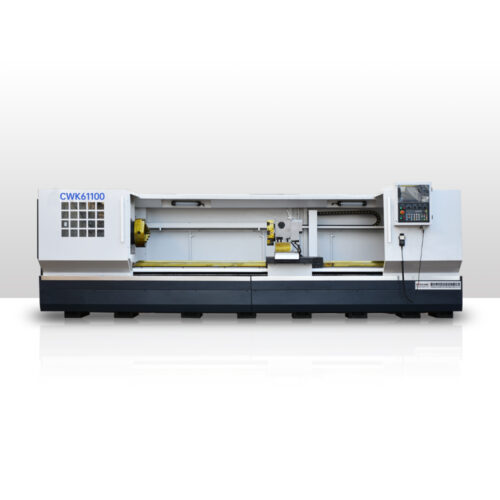

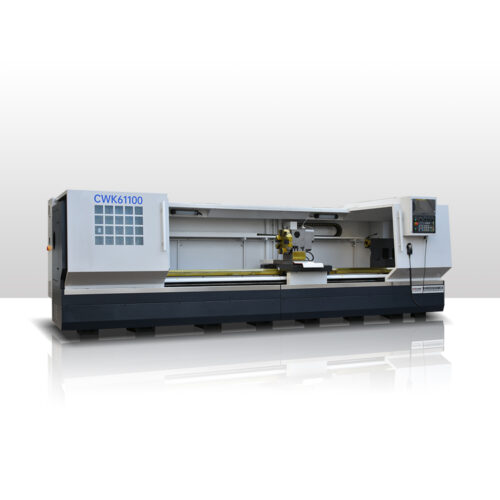

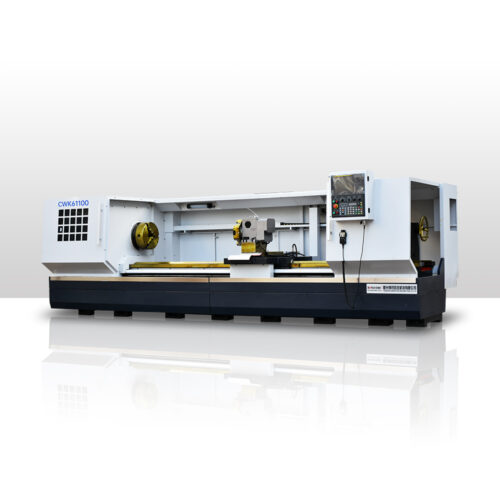

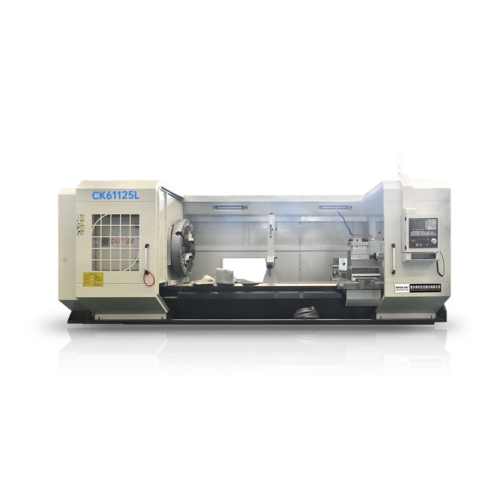

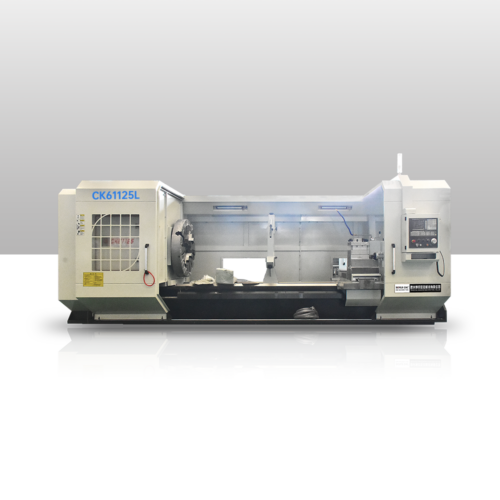

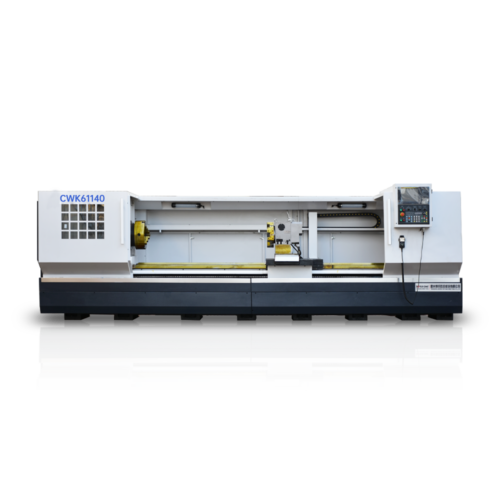

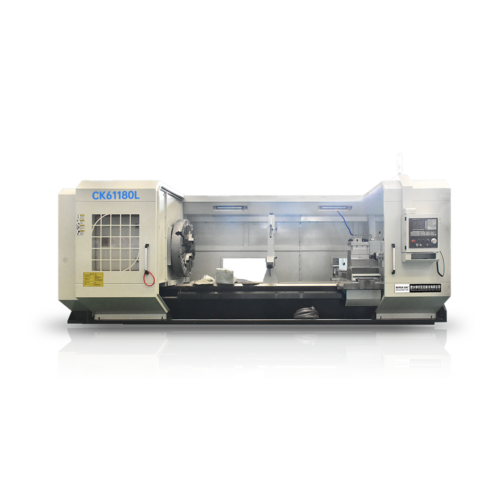

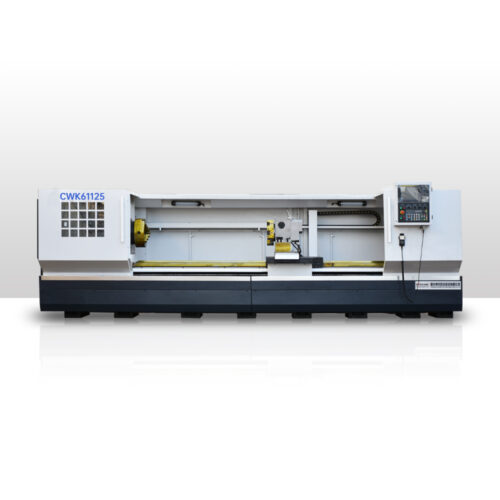

CWK Heavy Duty Flat Bed CNC Lathe Features

- More stable all-in-one bed

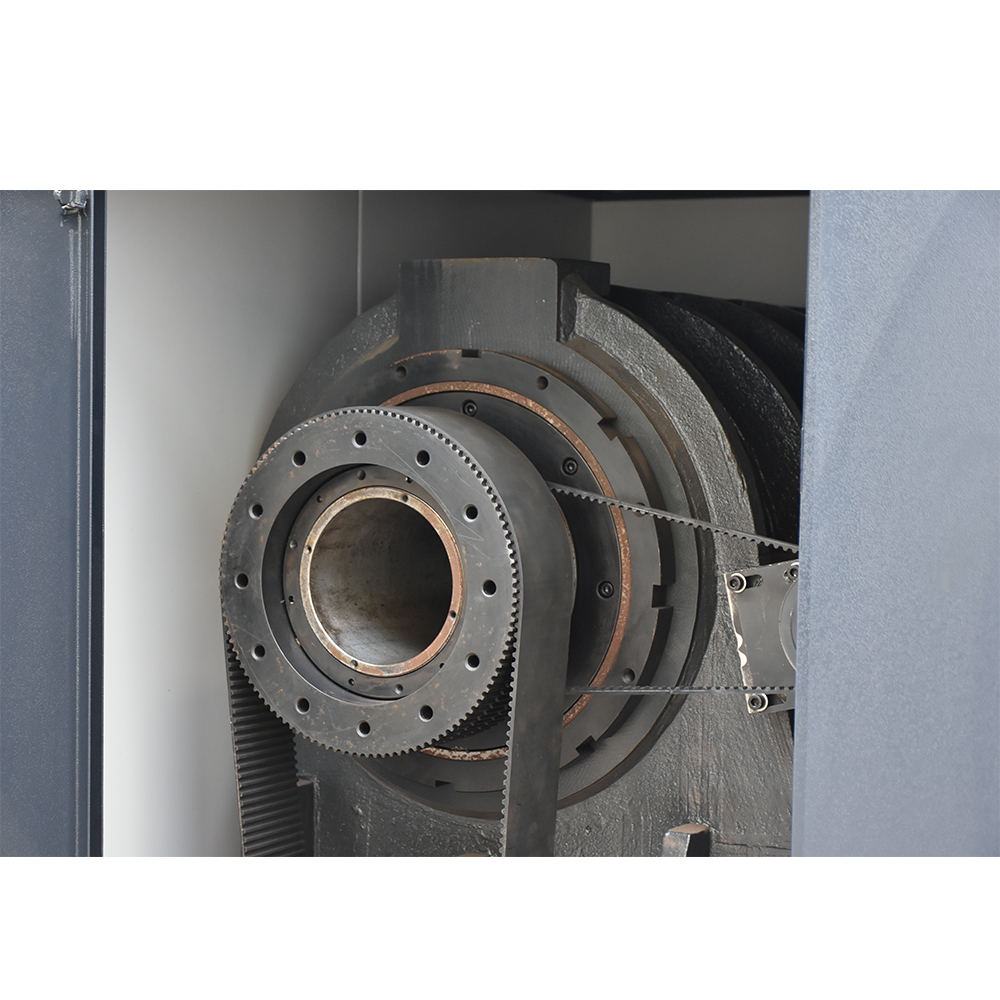

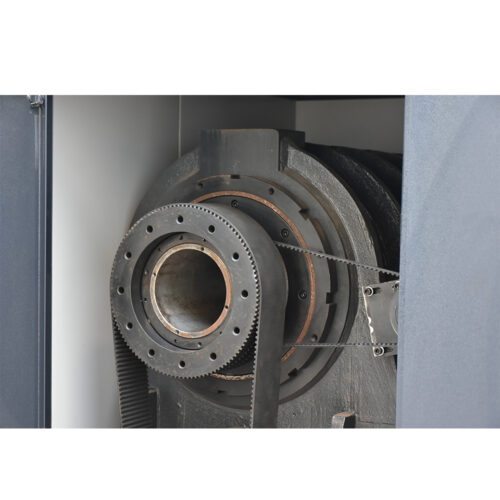

- Gear spindle speed, gear no step

- Higher rigidity base

- Wider laminate

- Integrated automatic lubrication system

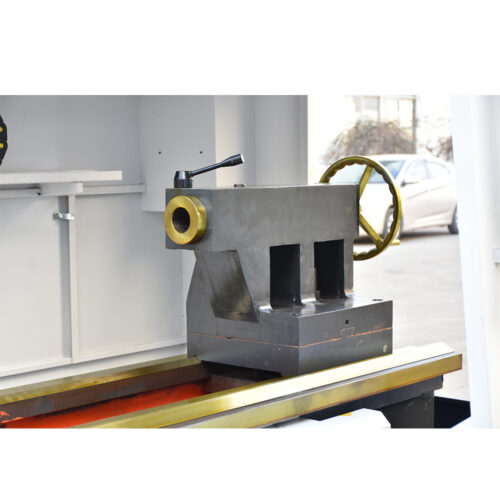

- Vertical 4 station tool post

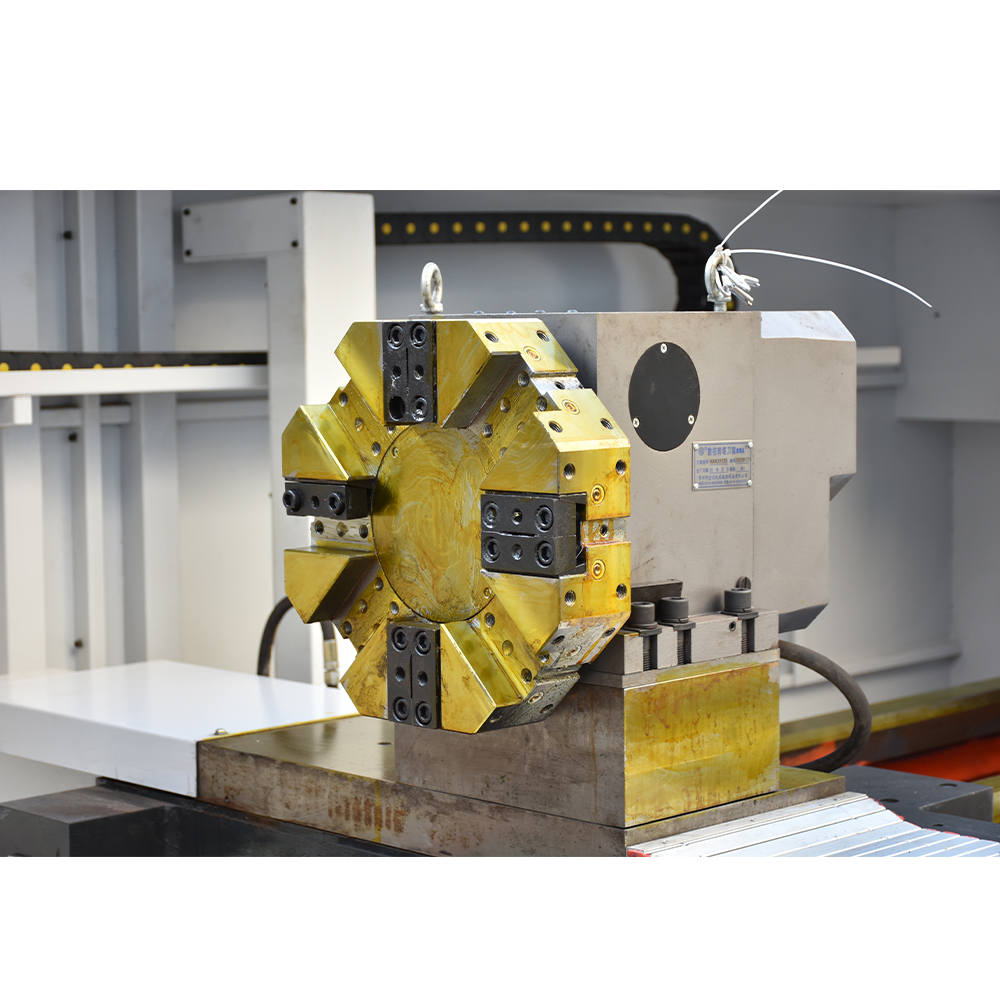

- Standard manual chuck optional hydraulic chuck

- Higher stability one-piece machine bed

- Standard: GSK Optional: FANUC, MITSUBISHIKND, SIEMENS

- 15kw motor

- Max spindle speed 950RPM, third step frequency conversion

- Dia of Spindle Thru-hole 105mm

- 4 station electric tool rest

- Toolbox and tools

- Frequency conversion step-less speed regulation

- Suitable for heavy cutting

- Servo spindle motor

- Manual tailstock

Product Video Display

Product Main Technical Parameters

|

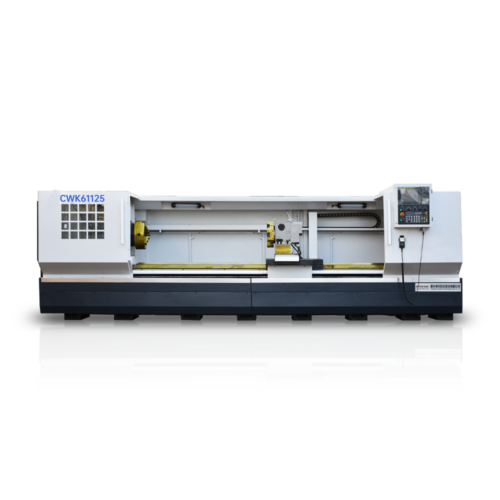

SPECIFICATION

|

UNIT

|

CWK61100

|

CWK61125

|

CWK61160

|

|

Swing over bed

|

mm

|

1000

|

1250

|

1600

|

|

Swing over cross slide

|

mm

|

610

|

850

|

1200

|

|

Distance between centers

|

mm

|

1500-8000

|

1500-8000

|

1500-8000

|

|

Guideway width

|

mm

|

755

|

755

|

755

|

|

Max. load capacity

|

T

|

6

|

6

|

6

|

|

Spindle bore

|

mm

|

130

|

130

|

130

|

|

Spindle bore taper

|

–

|

Metric φ160/MT6

|

Metric φ160/MT6

|

Metric φ160/MT6

|

|

Spindle nose type

|

–

|

A2-15

|

A2-15

|

A2-15

|

|

Spindle speed steps

|

–

|

VF. 4 steps

|

VF. 4 steps

|

VF. 4steps

|

|

Spindle speed range

|

rpm

|

4-300

|

4-300

|

4-300

|

|

Chuck

|

mm

|

φ1000 4-jaw manual

|

φ1000 4-jaw manual

|

φ1000 4-jaw manual

|

|

Turret/tool post

|

–

|

turret 4 position

|

turret 4 position

|

NC turret 4 position

|

|

Tool shank size

|

mm

|

40 x 40

|

40 x 40

|

40 x 40

|

|

X axis travel

|

mm

|

520

|

620

|

720

|

|

Z axis travel

|

mm

|

1350/2850/3850/4850/5850

|

1350/2850/3850/4850/5850

|

1350/2850/3850/4850/5850

|

|

X axis rapid traverse

|

mm/min

|

4000

|

4000

|

4000

|

|

Z axis rapid traverse

|

mm/min

|

6000

|

6000

|

6000

|

|

Tailstock quill diameter

|

mm

|

φ160

|

φ160

|

φ160

|

|

Tailstock quill taper

|

–

|

MT6

|

MT6

|

MT6

|

|

Tailstock quill travel

|

mm

|

300

|

300

|

300

|

|

Main spindle motor

|

kW

|

22

|

22

|

22

|

|

Coolant pump motor

|

kW

|

0.25

|

0.25

|

0.25

|

|

Width x Height

|

mm

|

2100 x 2100

|

2250 x 2300

|

2350 x 2600

|

|

Length

|

mm

|

5000/6500/7500/8500/9500

|

5000/6500/7500/8500/9500

|

5000/6500/7500/8500/9500

|

|

Net weight

|

T

|

10.0/11.5/12.5/13.5/14.5

|

11.0/12.5/13.5/14.5/15.5

|

13.0/14.5/15.5/16.5/17.5

|

Advantages Of Heavy Duty CNC Flat Bed Lathe

- The primary essential parts, such as the lathe bed, lathe feet, the middle supporting plate, and the spindle box, are all HT250 cast iron.

- The compact and reasonable symmetric structure ensures the essential parts’ high rigidity and bending vibration performance.

- The feed of X, Zdirection adopts the inner loop preloading large with double nut. It has a high feed speed.

- Both chuck and tailstock are available in hydraulic manual or pneumatic type.

- This flat bed CNC lathe also ensures the accuracy of drive and motion and machine service life.

- High-precision three-jaw chuck, high-rigidity cast iron casting. It has firm workpiece clamping and a long service life.

- Metal tailstock ensures the stability of machine tool processing.

- It is applicable for multi and mass production. The CNC flat bed lathe can meet the processing demands for complex and high-precision parts.

Reviews

There are no reviews yet.