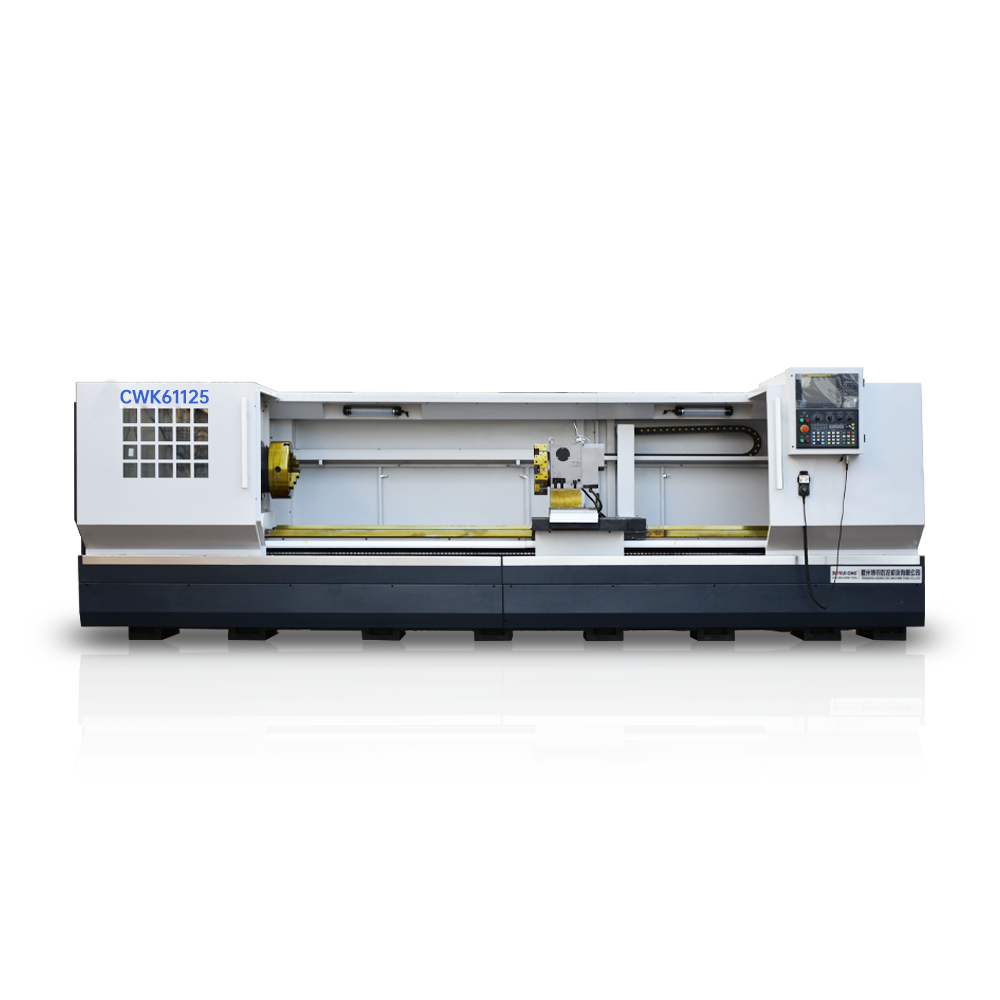

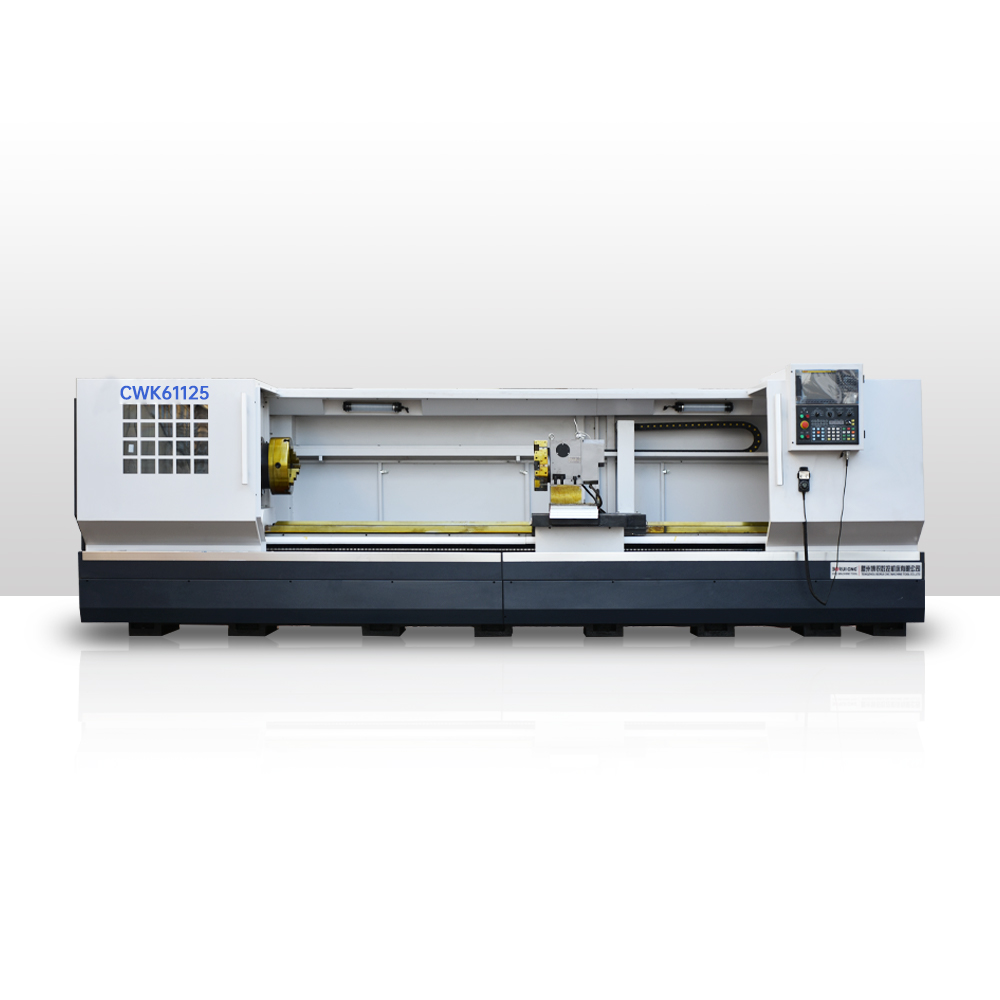

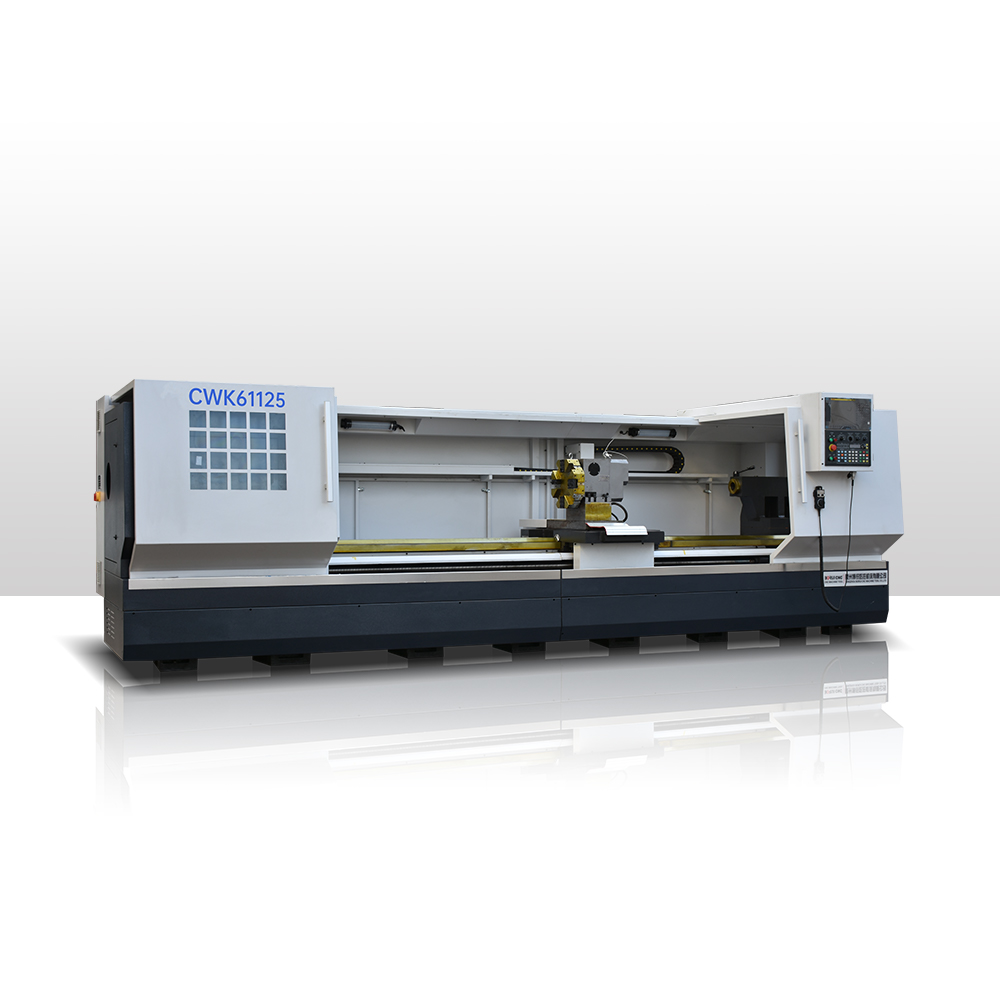

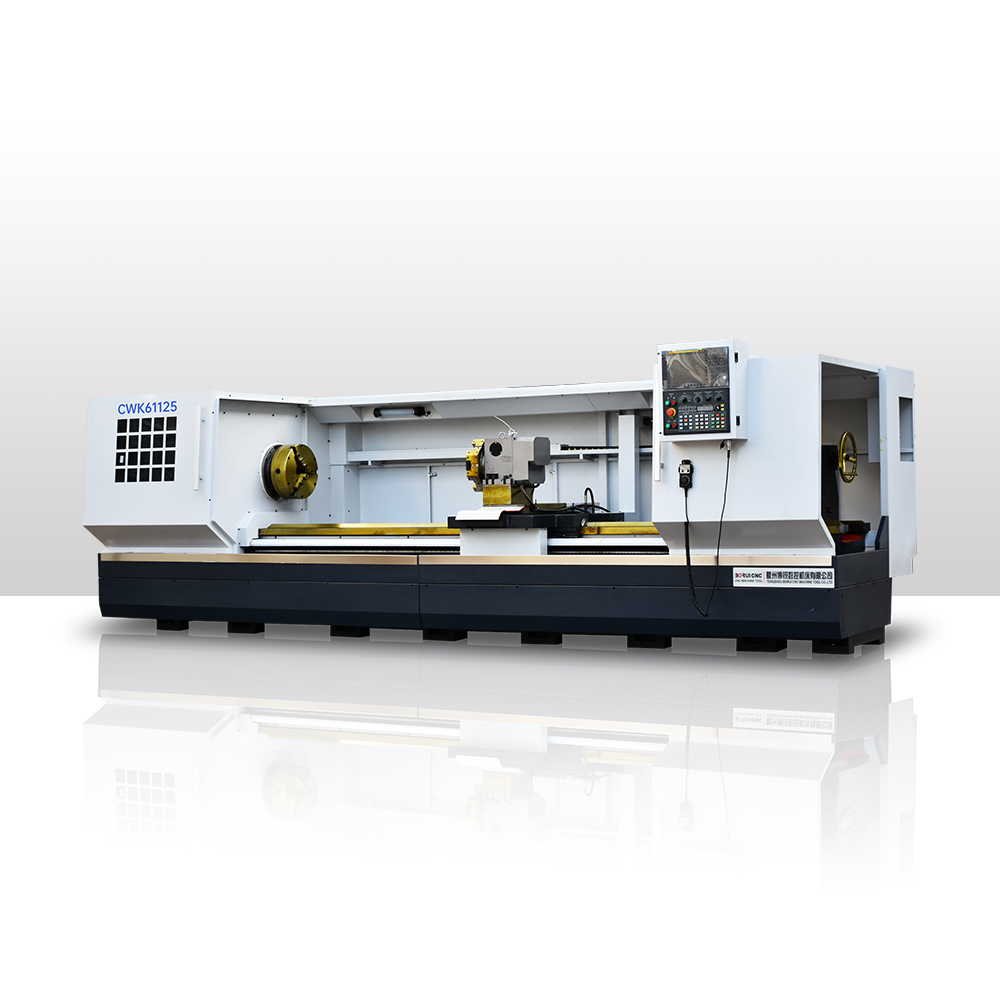

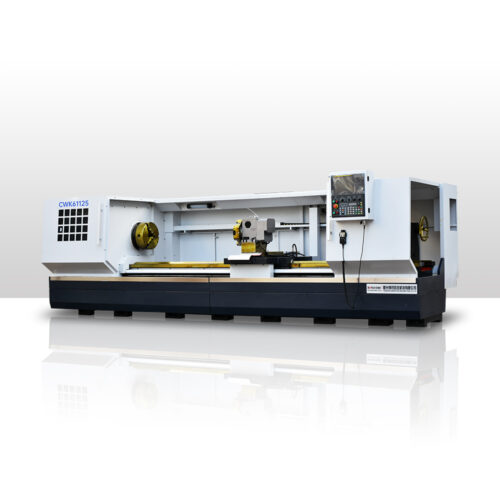

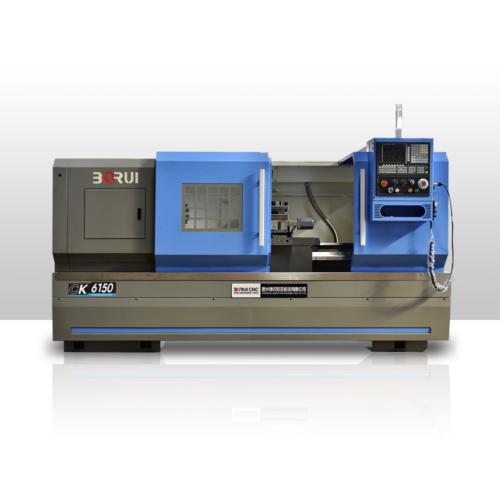

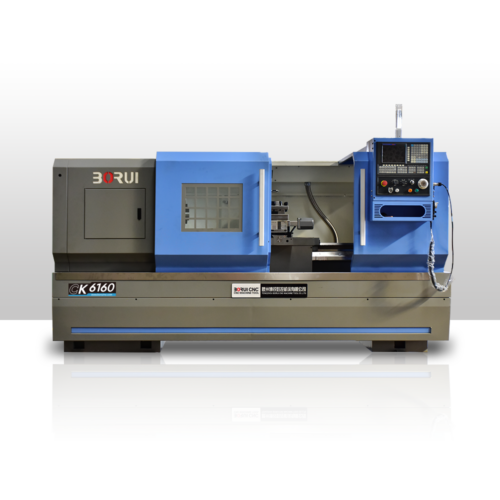

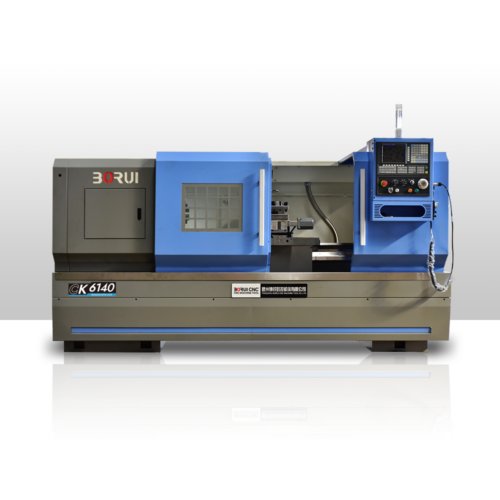

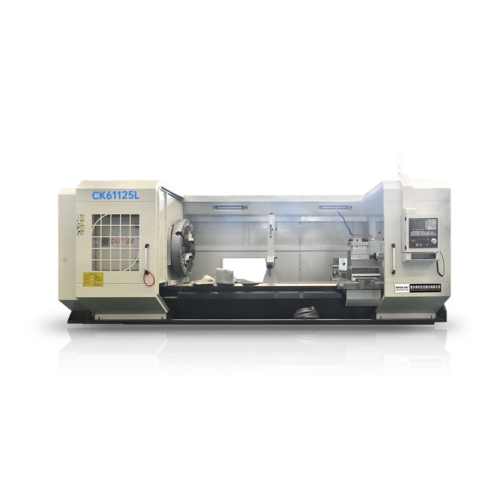

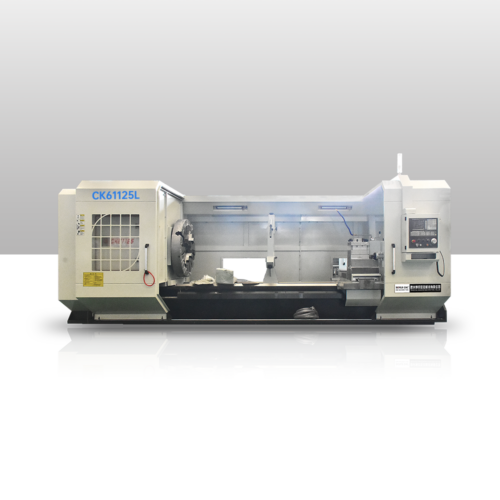

Advantages Of Heavy Duty CNC Flat Bed Lathe Machine:

- CNC Lathes designed for carrying or the operations of external turning, internal turning, facing, taper turning, profile turning and cutting of metric & Whitworth threads,etc;

- Spindle works at an infinitely variable speed under the control of a frequency converter.

- Their bedways are hardened by the hyper acoustic quenching method and finish ground, thus assuring high working accuracy for the machines.

- Upon request, the machine can be equipped with a Siemens CNC system or a Fanuc system or GSK system .

- The machine can be arranged with a pneumatic chuck, a hydraulic chuck or any other options as is required by the user.

- High-precision three-jaw chuck, high-rigidity cast ironcasting, firm workpiece clamping and long service life.

- X / Z to the use of domestic famous precision ball screw.

- Spindle bearings using domestic famous products.

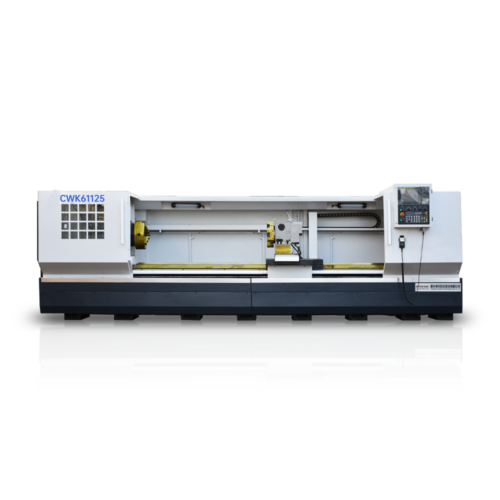

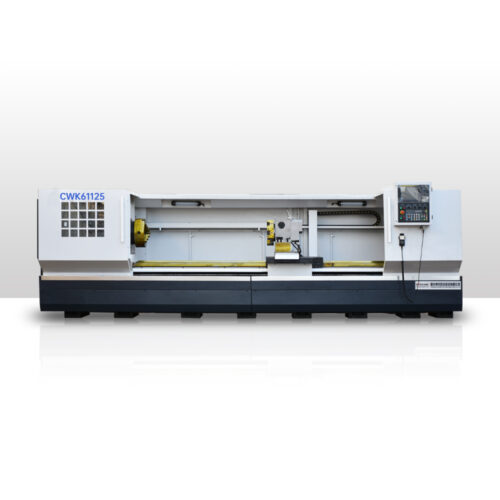

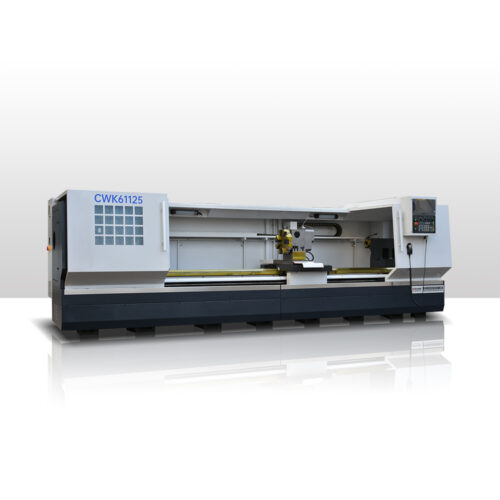

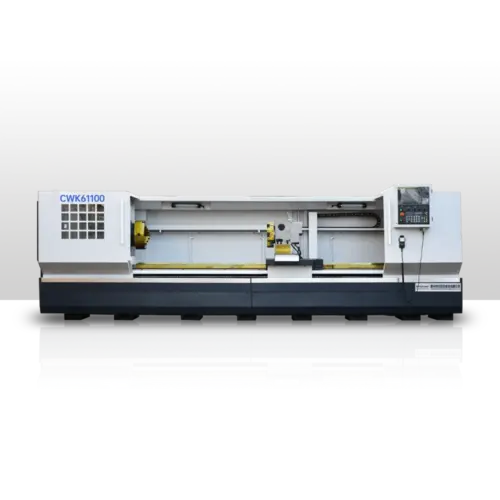

Product Main Technical Parameters:

| SPECIFICATION | UNIT | CWK61125 |

|---|---|---|

| Swing over bed | mm | 1250 |

| Swing over cross slide | mm | 850 |

| Distance between centers | mm | 1500-8000 |

| Guideway width | mm | 755 |

| Max. load capacity | T | 6 |

| Spindle bore | mm | 130 |

| Spindle bore taper | – | Metric φ160/MT6 |

| Spindle nose type | – | A2-15 |

| Spindle speed steps | – | VF. 4 steps |

| Spindle speed range | rpm | 4-300 |

| Chuck | mm | φ1000 4-jaw manual |

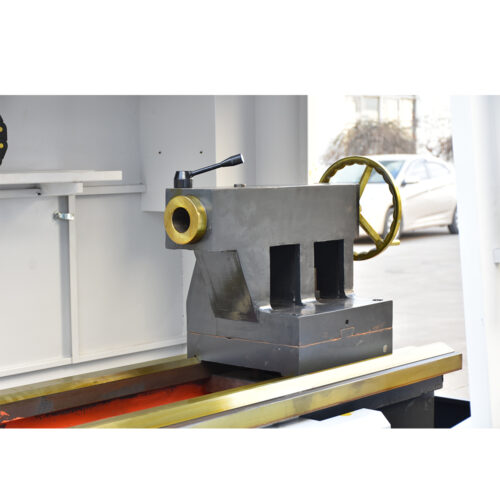

| Turret/tool post | – | turret 4 position |

| Tool shank size | mm | 40 x 40 |

| X axis travel | mm | 620 |

| Z axis travel | mm | 1350/2850/3850/4850/5850 |

| X axis rapid traverse | mm/min | 4000 |

| Z axis rapid traverse | mm/min | 6000 |

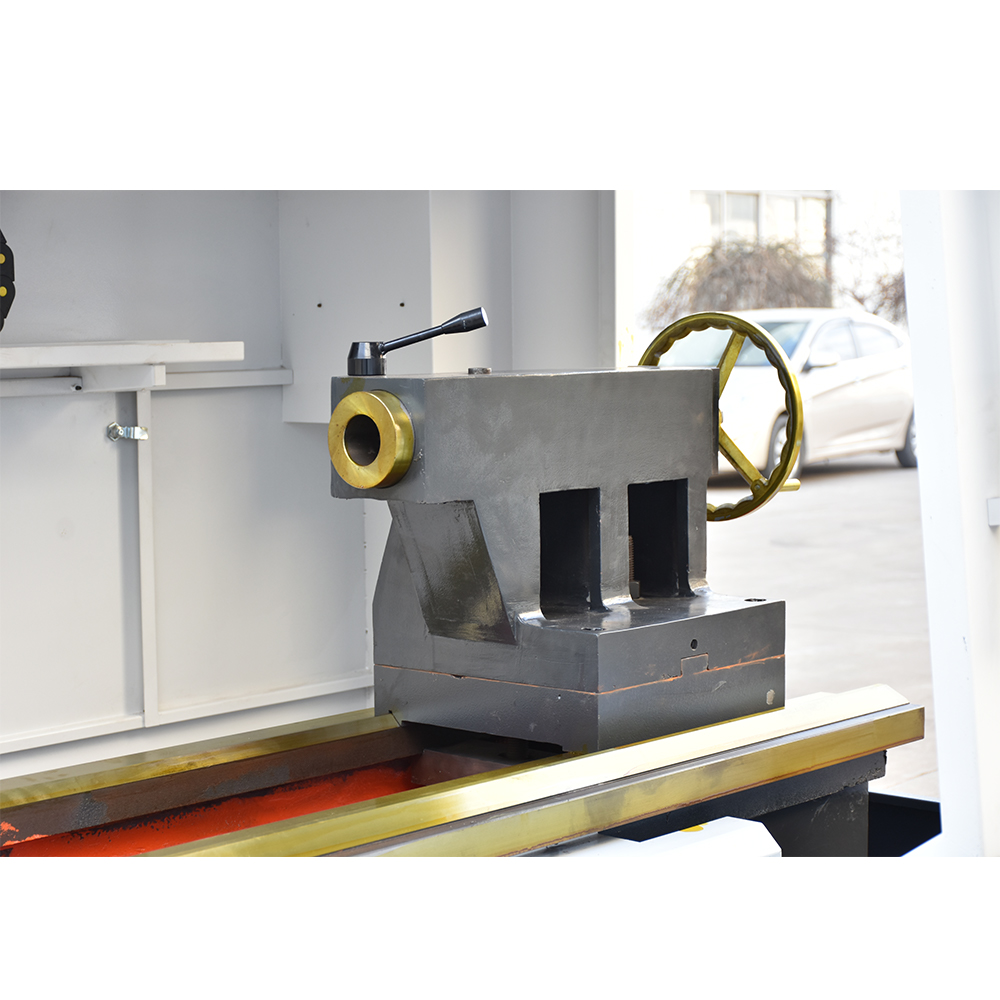

| Tailstock quill diameter | mm | φ160 |

| Tailstock quill taper | – | MT6 |

| Tailstock quill travel | mm | 300 |

| Main spindle motor | kW | 22 |

| Coolant pump motor | kW | 0.25 |

| Width x Height | mm | 2250 x 2300 |

| Length | mm | 5000/6500/7500/8500/9500 |

| Net weight | T | 11.0/12.5/13.5/14.5/15.5 |

Video Display

Reviews

There are no reviews yet.