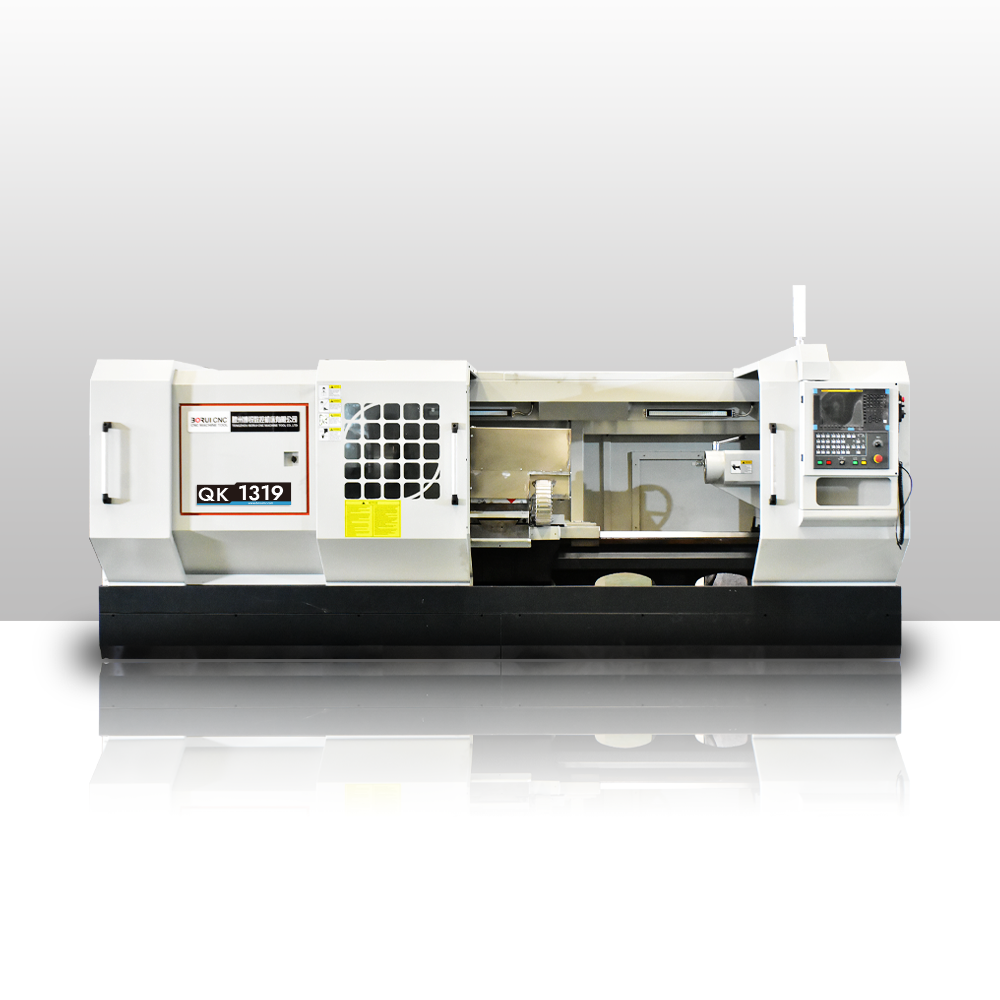

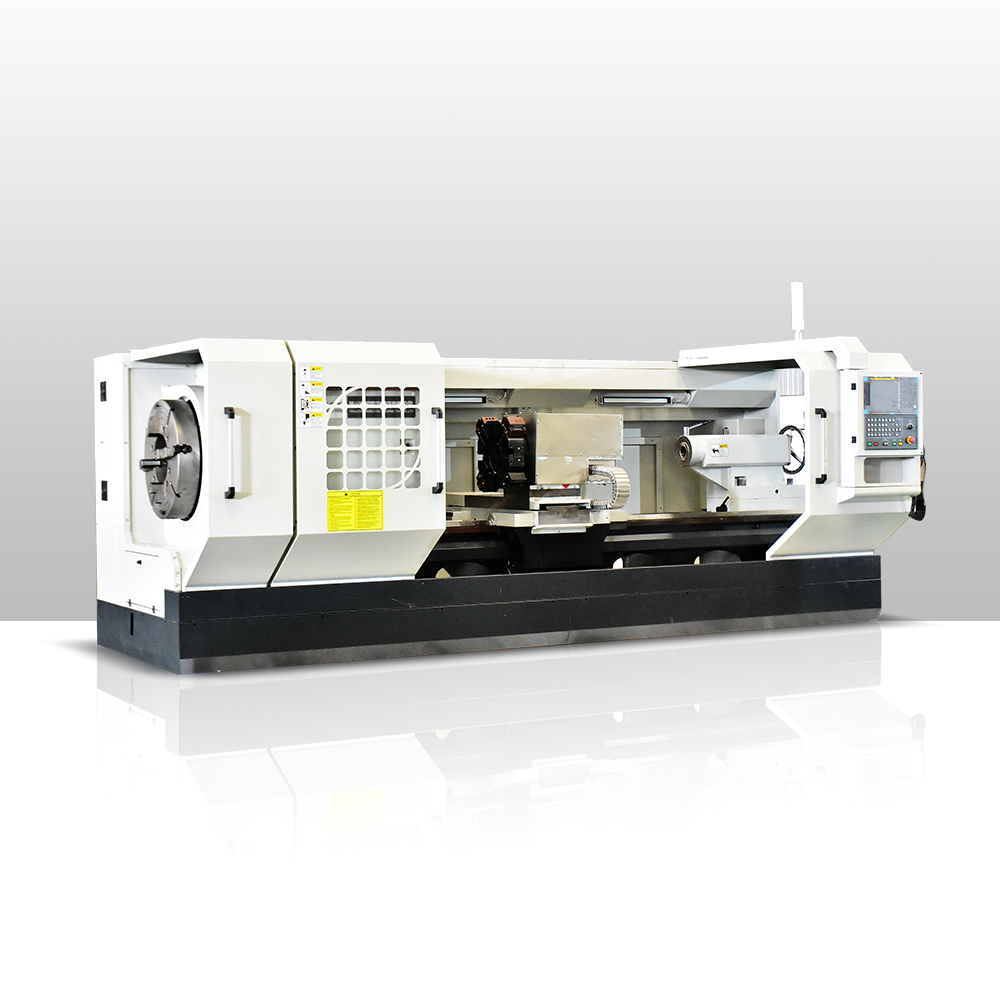

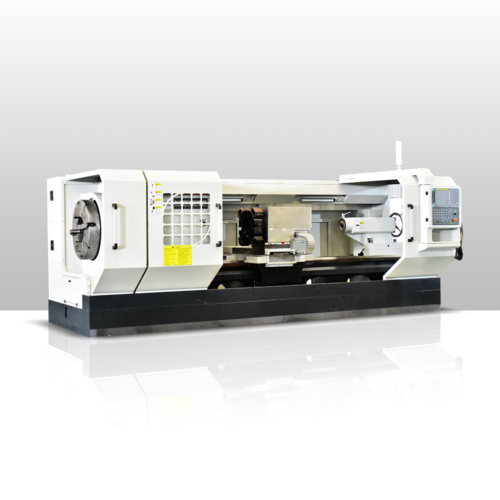

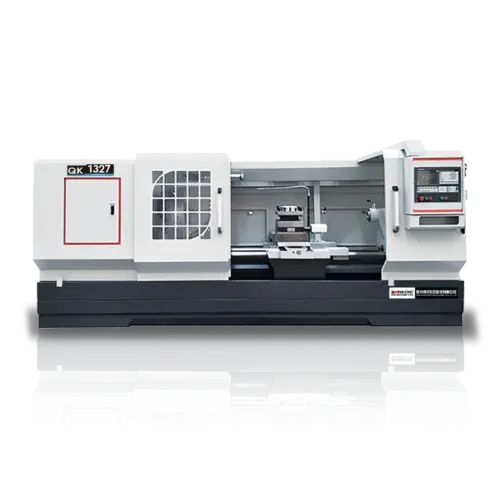

QK1319 CNC Pipe Threading Lathe Machine Features

- Automatic lubrication

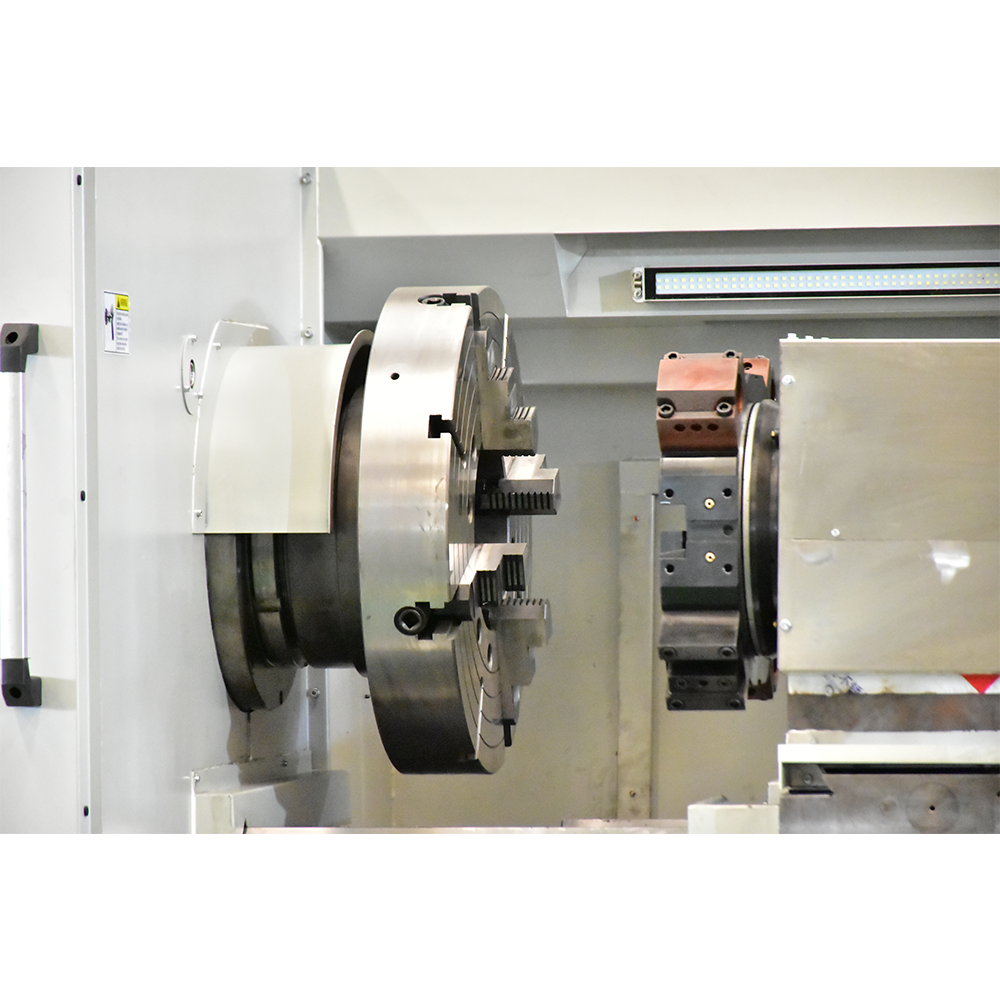

- Jaw manual

- Automatic lubrication

- Turning cooling system

- Tailstock manual

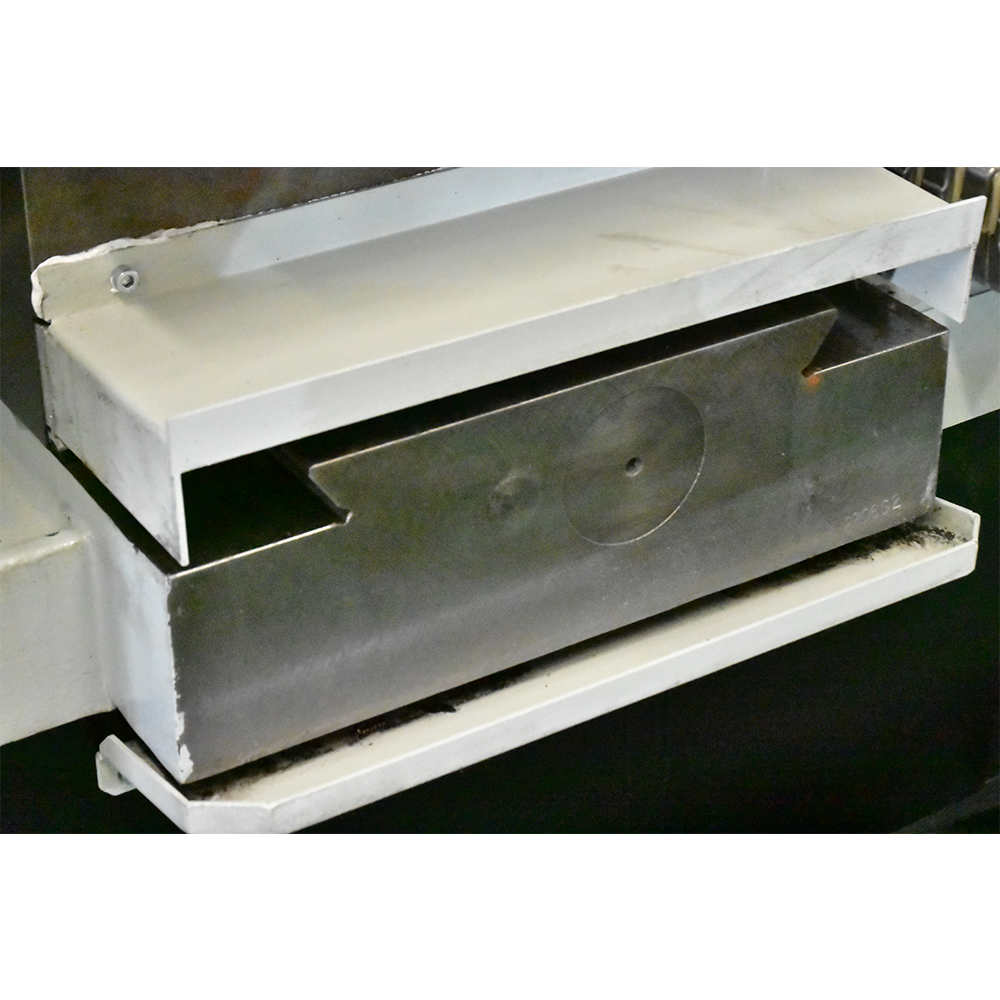

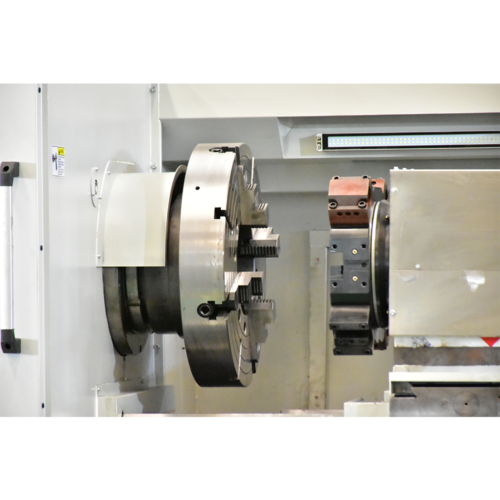

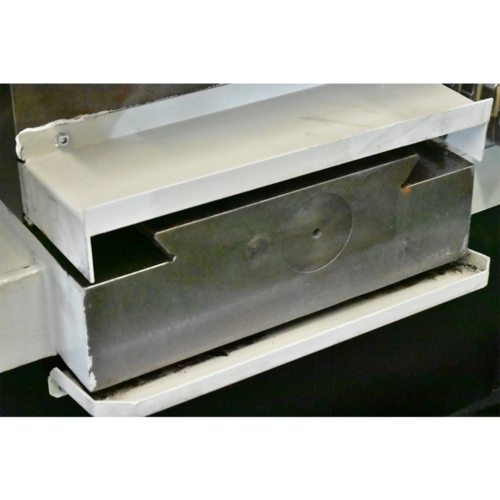

- Double chuck

- Lighting system

- 3 phase 380v 50Hz

- The rear bracket

- Semi-enclosed protective cover

- CNC turret 4 position

- Coolant system

- CNC system Standard: GSK, Optional: Siemens, Fanuc, Mitsubishi and others

Video Display

Technical Parameters of QK1319 CNC Pipe Threading Lathe Machine

|

SPECIFICATION

|

QK1319

|

QK1322

|

QK1325

|

QK1327

|

QK1338

|

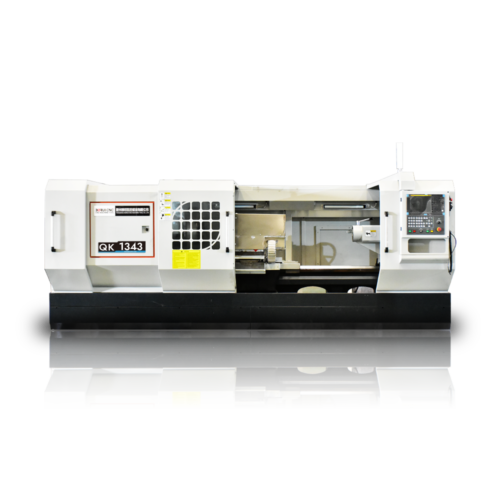

QK1343

|

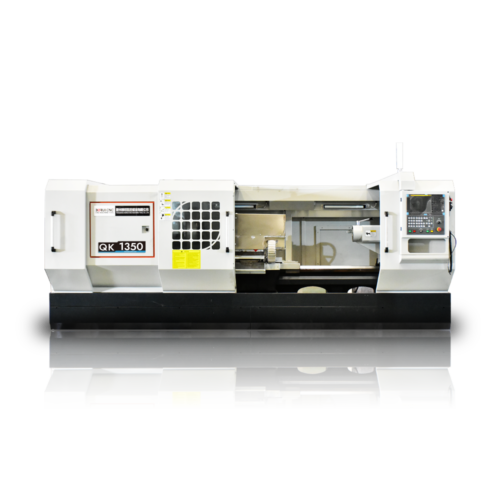

QK1350

|

QK1363

|

|

|

Swing over bed

|

mm

|

630/800

|

630/800

|

800-1000

|

1000

|

1000

|

1000

|

1200

|

1500

|

|

Swing over cross slide

|

mm

|

340/520

|

340/520

|

480-680

|

310

|

610

|

610

|

710

|

900

|

|

Distance between centers

|

mm

|

1000-6000

|

1000-6000

|

1000-6000

|

1500-6000

|

1500-6000

|

1500/3000

|

1500/3000

|

1500/3000

|

|

Pipe threading range

|

mm

|

50-193

|

50-220

|

50-255

|

130-270

|

190-380

|

270-430

|

330-510

|

330-630

|

|

Guideway width

|

mm

|

550

|

550

|

600

|

755

|

755

|

755

|

765

|

1100

|

|

Max. load capacity

|

T

|

3

|

3

|

4

|

6

|

6

|

6

|

6

|

10

|

|

Spindle bore

|

mm

|

206

|

225

|

255

|

280

|

300

|

440

|

520

|

640

|

|

Spindle speed steps

|

–

|

VF.4 steps

|

VF.4 steps

|

VF.4 steps

|

VF.4 steps

|

VF.3 steps

|

VF.3 steps

|

VF.3 steps

|

VF.3 steps

|

|

Spindle speed range

|

rpm

|

20-600

|

20-600

|

20-420

|

10-320

|

8-205

|

8-205

|

8-190

|

2-120

|

|

Chuck

|

mm

|

Φ500/3-jaw manual

|

Φ500/3-jaw manual

|

Φ630/4-jaw manual

|

Φ800/4-jaw manual

|

Φ850/4-jaw manual

|

Φ1000/4-jaw manual

|

Φ1000/4-jaw manual

|

Φ1250/4-jaw manual

|

|

Turret/tool post

|

–

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

NC turret 4 position

|

|

Tool shank size

|

mm

|

32×32

|

32×32

|

32×32

|

40×40

|

40×40

|

40×40

|

50×50

|

50×50

|

|

Y axis travel

|

mm

|

320/420

|

320/420

|

420

|

520

|

520

|

520

|

520

|

750

|

|

Z axis travel

|

mm

|

1000-6000

|

1000-6000

|

1000-6000

|

500-6000

|

500-6000

|

1250-2750

|

1250/2750

|

1250-2750

|

|

X axis rapid traverse

|

mm/min

|

4000

|

4000

|

4000

|

4000

|

4000

|

4000

|

4000

|

4000

|

|

Z axis rapid traverse

|

mm/min

|

6000

|

6000

|

6000

|

4000

|

4000

|

4000

|

4000

|

4000

|

|

Tailstock quill diameter

|

mm

|

φ100

|

φ100

|

φ120

|

φ160

|

φ160

|

φ160

|

φ160

|

φ260

|

|

Tailstock quill taper

|

mm

|

MT5/MT6

|

MT5/MT6

|

MT6

|

MT6

|

MT6

|

MT6

|

MT6

|

MT8

|

|

Tailstock quill travel

|

mm

|

250

|

250

|

250

|

300

|

300

|

300

|

300

|

300

|

|

Main sindle motor

|

kW

|

11

|

11

|

15

|

22

|

22

|

22

|

22

|

37

|

|

Coolant pump motor

|

kW

|

0.25

|

0.25

|

0.25

|

0.25

|

0.25

|

0.25

|

0.25

|

0.25

|

|

Width x Height

|

mm

|

1880×1850

|

1880×1850

|

1930×1900

|

2050×2050

|

2220×2120

|

2220×2120

|

2300×2200

|

2500×2500

|

|

Length

|

mm

|

3000/8300

|

3000/8300

|

3600/8600

|

4950/9450

|

5000/9500

|

5000/6500

|

5000/6500

|

5600/7100

|

|

Net weight

|

T

|

4.6-8.6

|

4.7-8.7

|

6-9.5

|

10.5-15.6

|

12/16.4

|

13/14

|

15/16

|

18/19.3

|

Advantages Of CNC Pipe Threading Lathe Machine

- We set up TRB (tapered rolling bearings) on this lathe to increase the rigidity of the spindle.

- The spindle bore is very large and set up double chucks both front and back. You can choose electric chucks as you like.

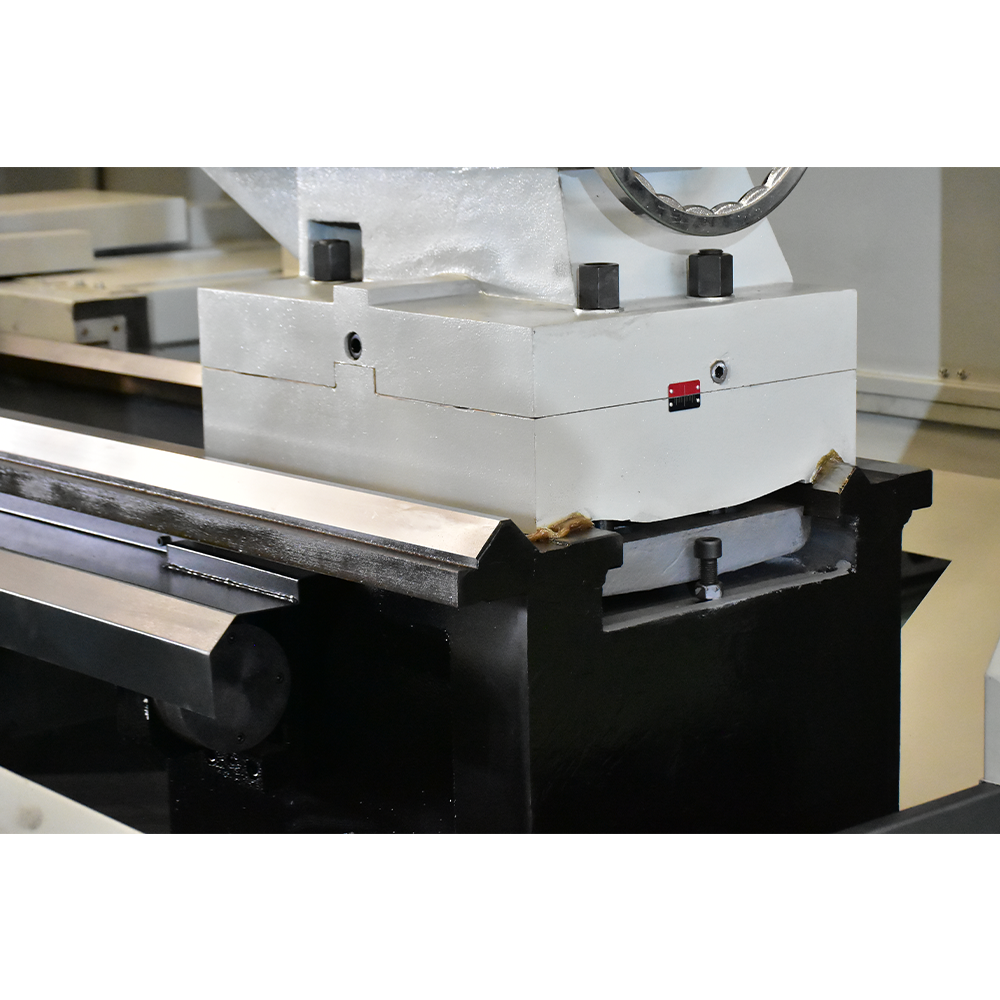

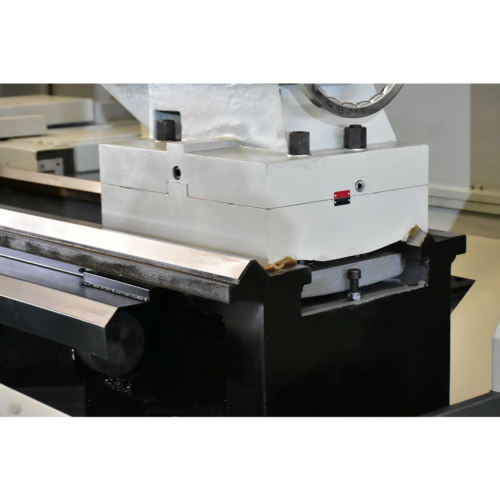

- The super audio quench treats the surface of the slide rail of the bed. It can be endurable and wear-resistant.

- To avoid crawling, the slide rail of the saddle is treated by a wear-resistant layer coated.

- There are two types of speed change: Manual and stepless.

- Set up a self-lubrication system that is easy to maintain.

- The main components, such as the bed base, the bed, and the headboard, are all cast from high-strength materials. It can ensure the long-term use of the machine tool.

- QK1319 CNC pipe threading lathe is mainly used for processing inner and outer pipe thread.

Reviews

There are no reviews yet.