A flatbed CNC lathe is mainly used for heavy-duty turning and can make discs, short shafts, and complex shapes. It can also make different internal and external metric or imperial values threads. When put on the flat bed CNC machine, the rotary head can mill or drill the workpiece’s edge and around its edge. The flat bed CNC lathe can drill, ream, expand, roll, and turn the outer circle, slot, and chamfer. It’s stable, productive, and can efficiently machine various materials.

A slant bed CNC lathe usually comes with a multi-station turret or live gear. This automatic machine tool can work quickly and accurately with more precision. For prototypes or series production, the slant bed lathe works best for making small to medium-sized airplane and car parts. It can also be used to make straight and slant cylinders, circular arcs, and complex shapes like threads and grooves. One of the well-known benefits is that it removes chips better than other tools. The chips are made when CNC turns or mills are moved to the chip bed by coolant flow and gravity. This feature also keeps the guides and other working parts from wearing out too quickly, which makes the machine last longer.

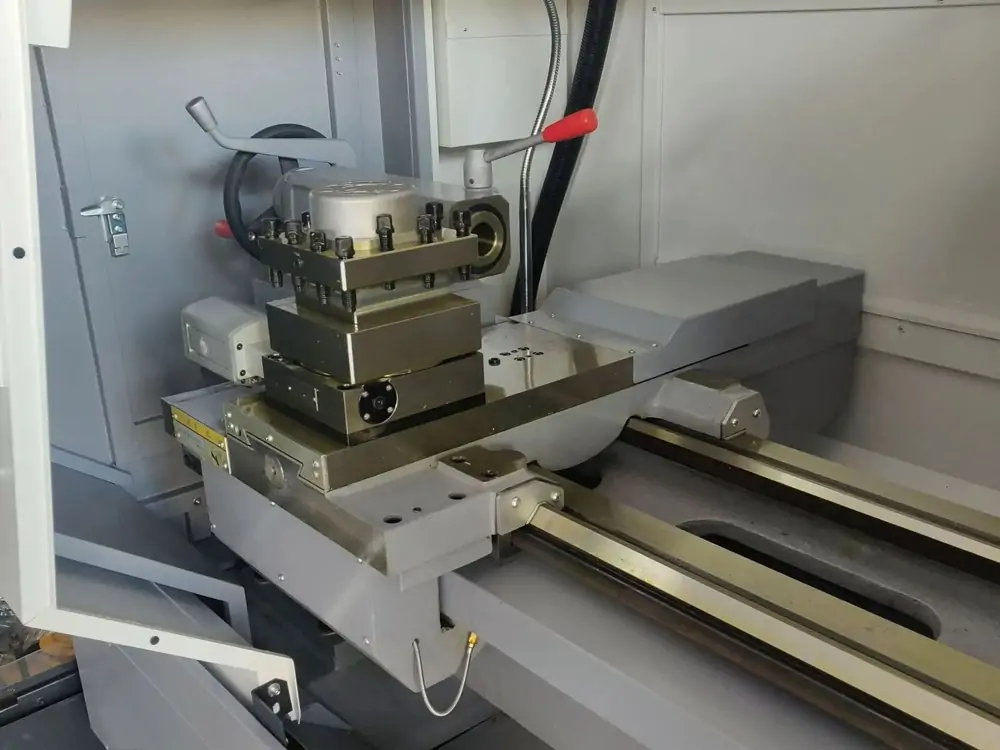

What is A Flat Bed Lathe Machine?

A flat bed CNC lathe is often used for heavy turning. It is often utilized to make discs, short shafts, complex shapes, and other workpieces. It can also make all internal and external threads in English or metric sizes. The rotary head can be put on the flat bed CNC lathe, and the workpiece’s edge and diameter can be milled or drilled. The CNC flat bed lathe can do more than turn the outside circle, groove, and angle. It can also prepare, ream, expand, roll, and do other things. It can do a lot of different kinds of work and is stable and productive.

What is A Slant Bed CNC Lathe?

Most slant bed CNC lathes have a multi-station turret or a power turret. This is a high-precision, high-speed, and accurate automatic machine tool. Most of the time, slant bed lathes are used to make medium-sized parts for airplanes, cars, and even lighters for glasses. They can also be utilized to make straight and diagonal cylinders, arcs, and more complicated parts like threads and slots. There are many benefits to using a slant bed CNC machine. One of the most well-known is that it helps chip drainage. The chips that are made during CNC turning or machining will be washed down toward the chip bed by gravity and the coolant’s regular flow. This keeps the chips from building up. This feature can also save the rails and other moving parts from wearing out too quickly, making the machine last longer.

Difference Between Flat Bed CNC Lathe And Slant Bed CNC Lathe

Machine Layout

The two guidelines are straight from each other on a flat bed CNC lathe. The ground and the plane of the two guide rails of the slant bed CNC lathe meet to make a sloped plane that is 30°, 45°, 60°, and 75° off-center. The slant bed CNC lathe bed is a right-angle triangle, and the flat bed CNC lathe bed is a square. A slant bed can move farther in the X direction than a flatbed with the same width as the guide rail. Because of this, the slant bed lathe is better because it lets you set up more tool positions.

Hard Turning Performance

The slant bed CNC lathe has a more extensive cross-sectional area with the same work envelope as the flat bed. It means that it is more resistant to bending and torsion. The direction of the workpiece’s gravity is the same as the cutting force. This makes the spindle run more efficiently and makes it harder to make the turning vibration. The cutting force between the tool and the workpiece is 90° to the workpiece’s gravity when it is being turned on a flat bed CNC machine. It is easier for the workpiece to vibrate.

Machining Accuracy/Repeatability

The CNC slant bed lathe is very accurate thanks to its linear guideway and high-precision ball screw. There is a small transmission gap between the screw and the nut, but there is still some room. If the screw goes backward, it will always create reverse clearance. It makes it harder to repeat the positioning and lowers the machining accuracy. The layout of the slant bed CNC lathe can change the X-ball screw’s clearance directly. Also, gravity works directly on the screw’s axial direction. It eliminates the reverse clearance of the transmission. But on the other hand, the x-directional screw of the flat bed CNC lathe is not affected by axial gravity, and the spacing cannot be taken care of directly. It is a benefit from how slant bed CNC lathes are built.

Chip Removal Performance

Because of gravity, the slant bed CNC lathe makes it hard for chips to wrap around the tool. It is suitable for chip removal, and the center screw and guide rail protect the sheet metal, so chips don’t build up on the screw and guide rail.

Slanted bed Most CNC lathes come with an automatic chip removal machine. This machine can remove chips automatically, which lets workers do more work in less time. Because of how the flat bed is set up, it is hard to add an active chip removal machine.

Automatic Production

By adding more lathe tools and changing how the automatic chip line is set up, the groundwork is being laid for fully automated production. The idea behind machine tool growth has always been for one person to watch over several machines. If you add milling power heads, automatic feeding machine tools or manipulators, automatic loading, one-time holding to do all the chip cutting, automatic blanking, and automatic chip removal, a slant bed CNC lathe turns into an automatic CNC lathe that wo

Automatic Production

By adding more lathe tools and changing how the automatic chip line is set up, the groundwork is being laid for fully automated production. The idea behind machine tool growth has always been for one person to watch over several machines. If you add milling power heads, automatic feeding machine tools or manipulators, automatic loading, one-time holding to do all the chip cutting, automatic blanking, and automatic chip removal, a slant bed CNC lathe turns into an automatic CNC lathe that wo

Differences in Nutshell

-

Slant bed CNC lathes are more stable, and flat bed CNC lathes are less flexible when moving tools and indexing.

-

A flatbed It is generally easier to work with significant parts on CNC lathes. Having some space between the headstock and the bed is also very helpful when the width of the part being turned gets bigger.

-

A straight line exists between the two guide rails on the flat bed lathe and the ground. When the ground plane and the plane of the two guide rails of the slant bed lathe meet, they make an angled plane that is 30°, 45°, 60°, and 75° steep.

-

The bed of a flatbed CNC lathe is square from the side of the machine, and the bed of a slant bed CNC lathe is a right triangle. If the guide rail is the same width, it’s clear that the slant bed’s x-direction carriage is longer than the flat bed’s. It means that more tool numbers can be set up.

-

The cross-sectional area of the CNC lathe with a slant bed is more significant than that of the flat bed with the same specs. This means that it can handle bending and twisting better. The slant bed CNC lathe’s cutter cuts from above at an angle to the workpiece. The cutting force is mostly in line with the workpiece’s center of gravity, so the spindle moves quickly, and cutting vibrations are hard to get. The cutting force of a flat bed CNC lathe is 90° to the weight of the workpiece, so it is easy for the machine to shake.

-

A flat bed lathe can work precisely with light and heavy items. For making medium-sized parts, slant bed lathes are the best choice.

-

Regarding automation, the slant bed is better than the flat bed, but it’s not easy to make.

FAQs

What is the difference between a CNC machine and a CNC lathe?

The cutting tools on a CNC lathe move around the object or bar stock to make a shape. In a CNC mill, on the other hand, the cutting tools move around the bar stock. These minor differences allow each machine to make specific shapes or cuts quickly and accurately.

What are the different types of lathe beds?

Beds come in different styles, such as inverted “V” beds and beds that combine “V” and flat beds. Flat beds are used for heavy work, while “V” and combination beds are used for fine and light work. The first thing to be done when setting up a lathe is to level it. It means making sure that the bed is not bent or bowed.

How many types of CNC lathe machines are there?

The amount of movement axes can tell you what kind of CNC lathe it is: 2-axis: can face, drill, tap, and machine parts with an outer or inner diameter. 3-axis—adds a live tool system for drilling, grinding, and other tasks. 4-axis: Usually adds a second tool holder or turret.