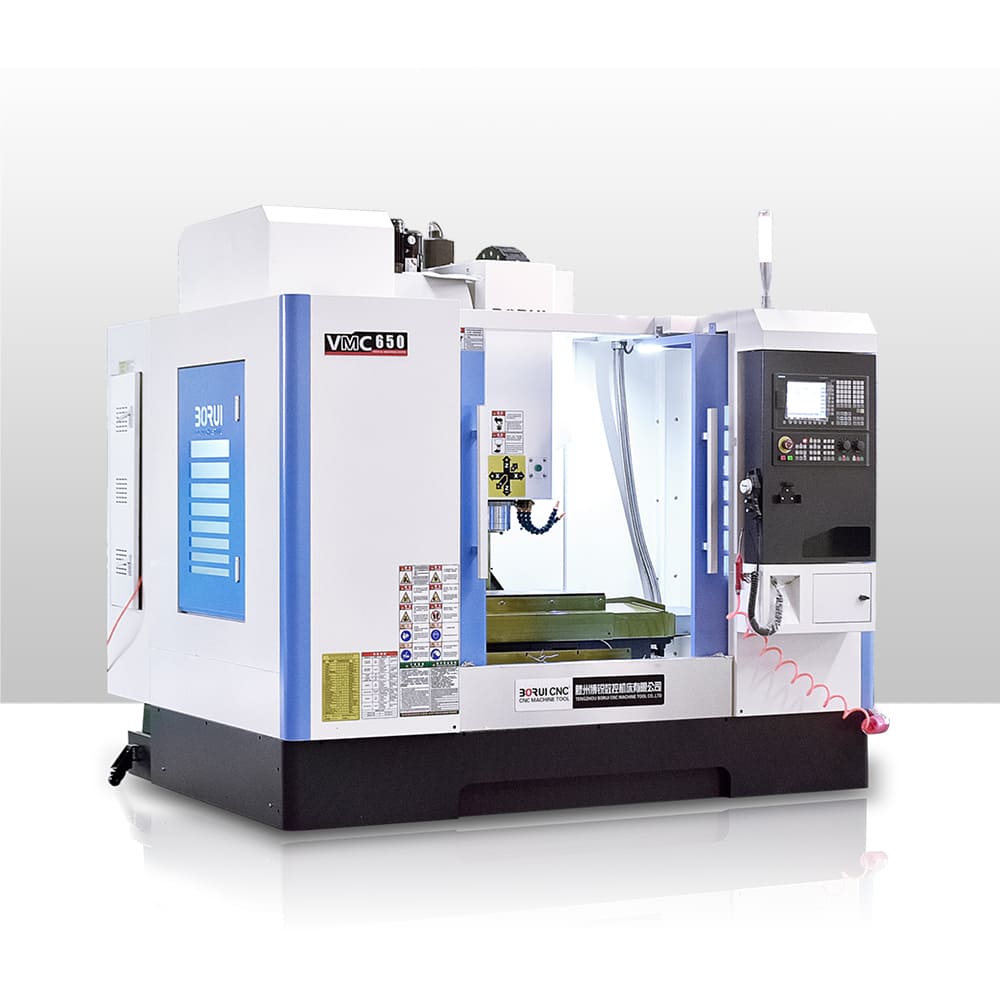

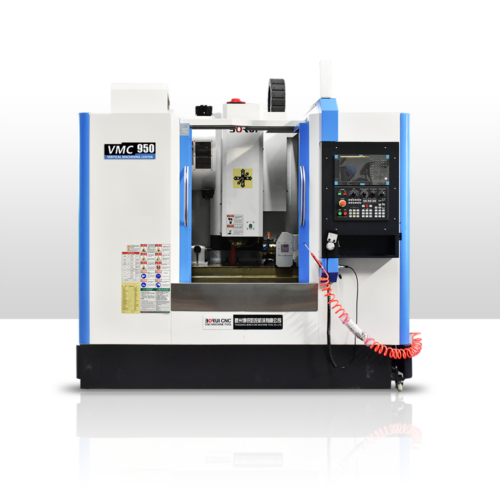

VMC650 CNC vertical machining center is mainly used for the processing of various metal molds, with high work efficiency and small footprint, which is very suitable for the processing of small and medium-sized workpieces.

https://www.youtube.com/watch?v=6i8kAamJpvo

Advantages of VMC650 5 Axis Vertical Machining Center:

- High density, twice quenching, vibration treatment.

- The double layer casting structure of sliding saddle is used to strengthen the stability of the bed.

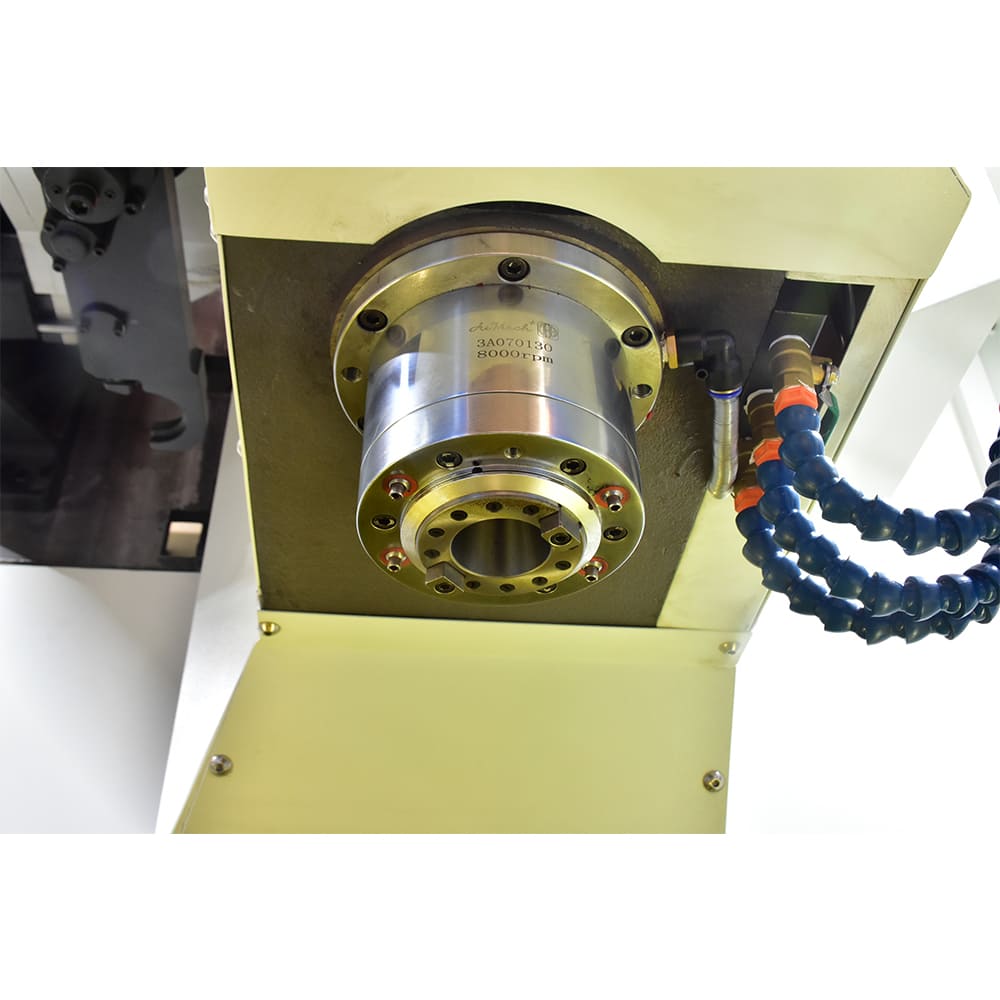

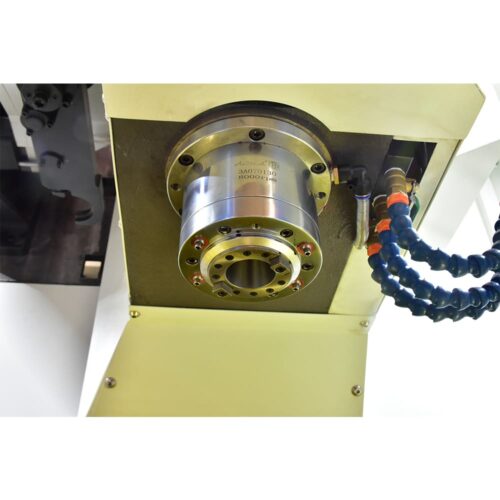

- All adopt Taiwan original spindle, high speed, high rigidity, simple and compact structure.High efficiency.

- Low noise, low vibration and high precision, stable processing products, optional.

- Using Taiwan silver linear guide rail, linear guide rail, small clearance, large bearing capacity, high rigidity, small friction loss, small wear, long service time, suitable for high-speed operation, sensitive response.

- Using Taiwan brand knife library 24 disc knife library, with high precision, high efficiency, stable tool change, high processing efficiency.

- Computer balance correction andrunning-in test, lengtheningservice life of the whole spindle.

-500x500.png)

Reviews

There are no reviews yet.