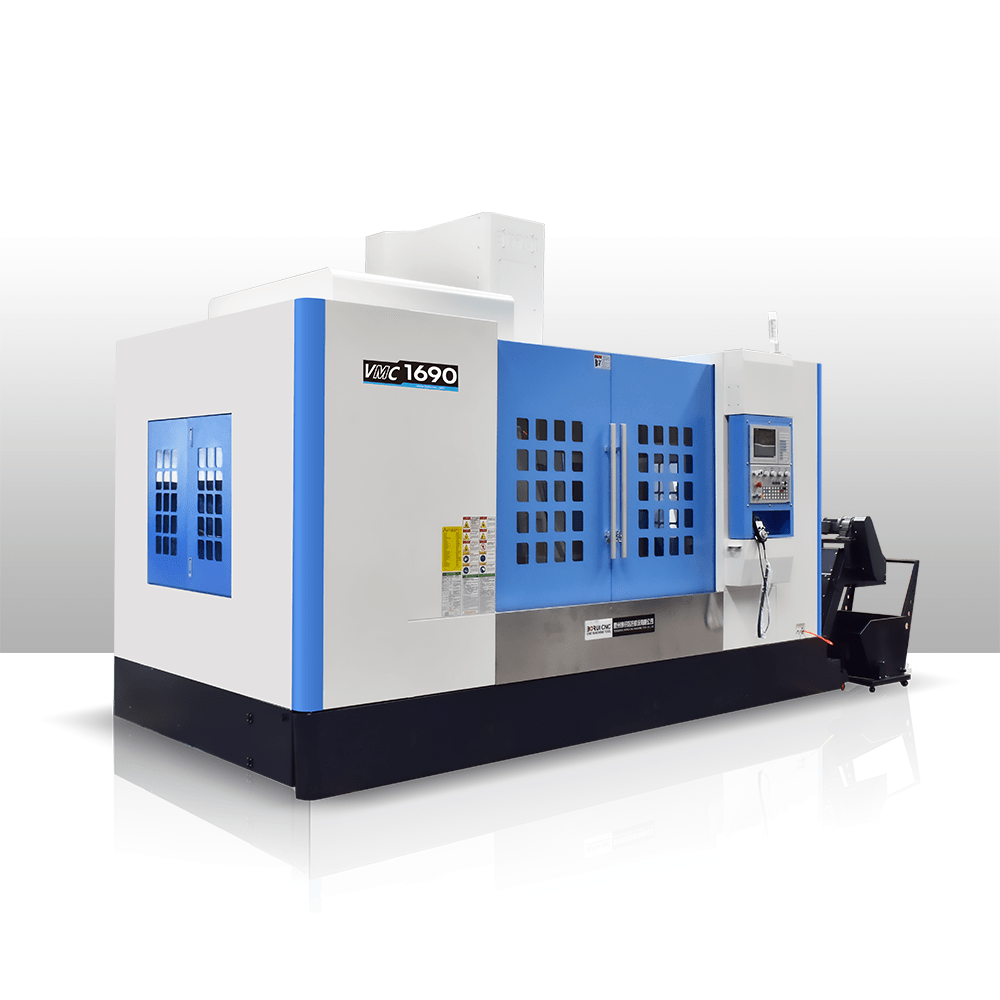

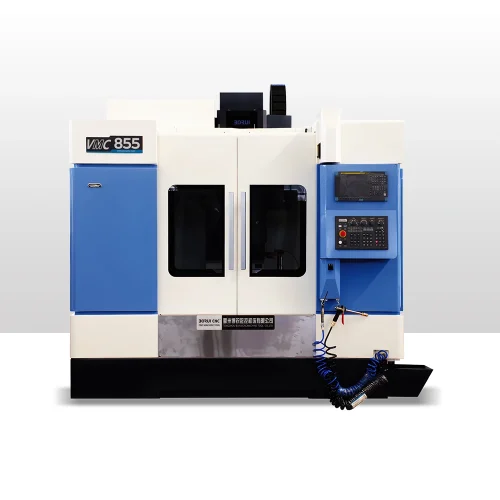

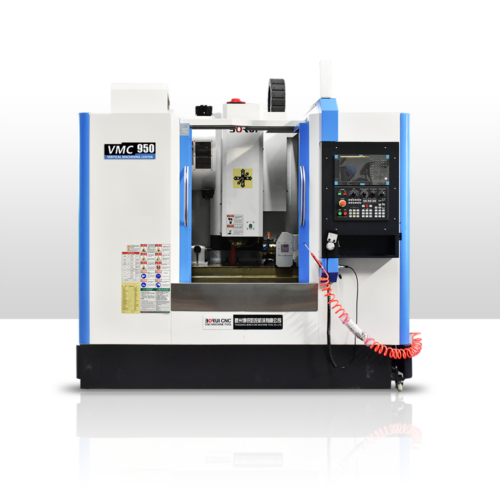

Features of VMC1690 CNC Vertical Machine Center

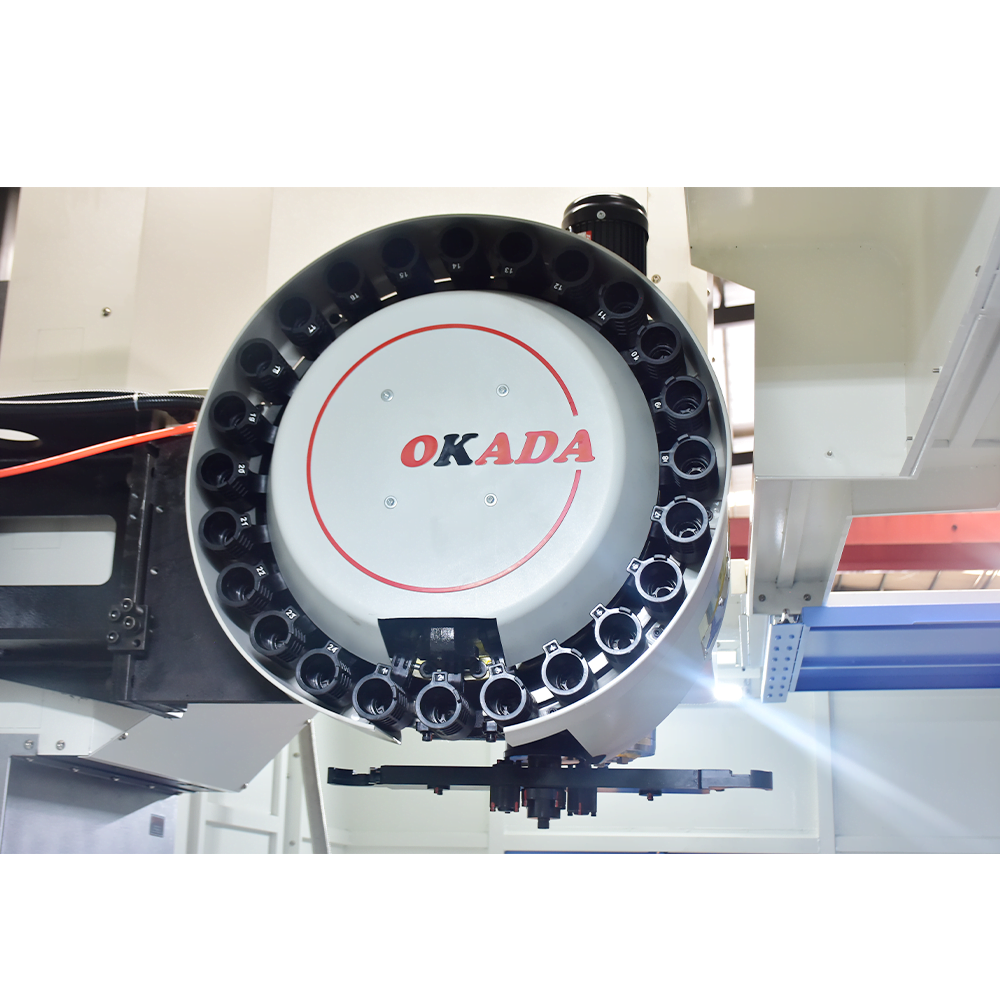

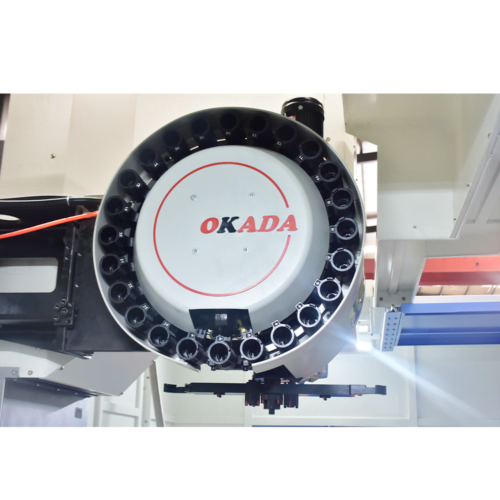

- 24 Disc ATC

- CNC CONTROL

- SIEMENS, KND, FANUC, Mitsubishi, GSK, and other operating

- Full protection

- Central automatic lubrication

- Three-axis lubricating system

- Separate hand-wheel

- Machine tool lighting work light

- Random technology document

- Spindle cone Hole cleaning air

- Electric cabinet cooling and heat exchanger

- Cleaning air gun

- Chip storage tank

- Servo transformer

- Foundation pad iron and adjusting bolt

CNC Vertical Machine Center Video Display

VMC1690 Machine Technical Parameters

| SPECIFICATIONS | UNITS | VMC1690 |

|---|---|---|

| Table size | mm | 1800×900 |

| X axis travel | mm | 1600 |

| Y axis travel | mm | 900 |

| Z axis travel | mm | 700 |

| Max. worktable load | kg | 1500 |

| T slot(number-width-pitch) | 5-22×165 | |

| Max. spindle speed | rpm | 6000 |

| Spindle taper | mm | BT50 |

| Main motor power | kw | 18.5/222 |

| X/Y/Z rapid traverse speed | m/min | 15/15/12 |

| Cutting feed speed | mm/min | 1-6000 |

| Guide rail type | Linear rail | |

| Distance from spindle axis to column surface | mm | 950 |

| Distance between spindle nose and worktable surface | mm | 170-800 |

| Positioning accuracy | mm | ±0.0075 |

| Repeat positioning accuracy | mm | ±0.01 |

| Tool magazine | 24(dis type) | |

| Machine weight | kg | 14000 |

| Overall dimension | mm | 4500X3350X3200 |

| Dimensions | mm | 2300X2200X2400 |

Advantages of VMC1690 Vertical CNC Machining Center

- The fuselage and main components are high-strength cast iron.

- High speed, high precision, high rigidity spindle unit.

- The lubrication system lubricates each drive and reduces friction resistance.

- Centralized chip removal with available chip removal machine.

- It can be equipped with a tool store to implement automatic tool change, saving the process of tool change time.

- The base adopts the structure of casting a large water tray, which has good waterproof performance.

- The main large parts of the machine tool: base, workbench, column, bed saddle, and spindle box are made of high-quality resin sand modeling.

Reviews

There are no reviews yet.