Introduction

The CNC machining industry constantly innovates to fill the functional voids one machine leaves. In the process, it creates machines that are distinct from one another.

One popular innovation in machining is the addition of cutting movements. As expressed in its “axis,” the more movement a machine has, the more capable and versatile it is.

Below, we compare the difference between a 3-axis and a 5-axis CNC machine. We detail their advantages and disadvantages and how they differ in different aspects.

What does Axis Mean?

Before we explain the featured machine tools, let’s first learn what the term “axis” means. After all, you’re likely asking yourself, too, “What is an axis in a CNC machine?”

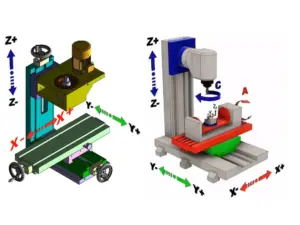

Like in most applications, the word “axis” denotes direction. In CNC machining, the term “axis” expresses the number of movements or directions the cutting tool or workpiece can move. Often, a machine tool will have at least three linear axes denoted as the XYZ axes respectively.

The X-axis refers to the linear movement of the cutting tool from right to left or vice versa. The Y-axis expresses the front-back movement, while the Z-axis denotes the top-bottom movement. In a 3-axis machine, the workpiece is often stationary while the cutting tool moves.

However, besides these linear axes, some machines feature rotary axes, denoted as ABC. The fourth Axis (A-axis) adds rotational movement around the X-axis. At the same time, the B-axis complements rotation with the Y-axis.

Adding rotary axes makes for a faster and more precise cutting process. Since more movement is added, the cutting tool can work on more sides and angles. This gives the machine better flexibility and added capabilities.

3-Axis Machining

A 3-axis CNC machine is a standard tool used in basic fabrication projects. It features a tool that can move along the XY and Z-axes for depth cutting. Other 3-axis CNC machines will have a moving table to accommodate the top-down movement, while the cutter is specific to the XY axes.

These tools move in linear directions and are limited to non-complex tasks. Three-axis machines are ideal for fabricating 2D or 2.5D objects but rarely on 3D complex designs. The geometries should be minimal if they are to accommodate 3D fabrication.

Three-axis CNC machines are best used for basic functions like cutting edges, drilling holes, or tapping. Their limited movement also means limited capacity and fabrication capacity.

Here are the most common types of 3-axis CNC machines in the market:

- CNC milling machines

- CNC lathe machines

- CNC drilling machines

5-Axis Machining

A 5-axis CNC machine operates on “XYZ plus AB” axes. In addition to the standard linear movements, two rotary movements are added. This allows the machine to work with complex and intricate shapes on an object.

The added movements will vary depending on the type of 5-axis machining tool. You can have a 5-axis CNC machine whose cutting tool only moves in XYZ axes but has a swiveling tool head and table between operations. You can also have a machine that allows the workpiece and cutter to rotate simultaneously during the operation. Another type uses a spindle that can be stationary or swivel in most directions.

The two more axes allow for more precise and versatile capabilities. With a 5-axis machine, you can create complex 3D workpieces with even smoother finish.

Continuous milling is also possible since the cutters can follow the design curvatures. You can approach a design at every angle and cut the need to reposition the workpieces. Even a complex 3D workpiece can be finished in a single operation.

Common 5-axis machines include:

- CNC routers

- Continuous 5-axis CNC machine

- 5-axis CNC millers

3-Axis Machine vs. 5-Axis Machine

The difference in the number of axes in these machines seems marginal. However, this simple difference separates the two in many aspects comparable. Let’s look at how the 3-axis compares to the 5-axis machines below.

1. Application

The 3-axis CNC machines are undeniably limited compared to the 5-axis variant. This limits the former to working on simple designs that do not need extra contours or angles. Often, 3-axis machines are the go-to for producing simple parts based on flat objects. They are ideal for doing straightforward tasks like drilling holes or cutting edges. 3-axis machines are common in making parts for automotive, electronics, and manufacturing.

In comparison, 5-axis machines fabricate precise parts for medical or aerospace use. Such machines provide a smoother finish and a more accurate output. These machines accommodate intricate geometries and rigorous details.

2. Production Speed

In this category, the 5-axis machine edges out the 3-axis machine. The limited XYZ movement in the 3-axis spells a slower turnaround time for fabrication. Not only does this limit the speed, but it also requires tool changes between operations. You must also manually reposition the workpiece, as the table does not swivel.

All these discrepancies are not a challenge in 5-axis machines. Not only does its added movement add speed, but it also eliminates tool changes. You can insert the workpiece and let the machine automate most of the work.

3. Maintenance

The rule of thumb in machining is that the more complex the machine gets, the harder it is to maintain. Maintenance for 3-axis machines is less demanding since they are simpler tools. With fewer moving parts and a smaller build, the 3-axis does not need extra measures to remain tip-top.

In contrast, the 5-axis machine will need more specific maintenance measures. The higher maintenance comes from the added moving parts and a complex structure. Due to more movements during operation, parts are more prone to wear and tear.

4. Efficiency

Without a doubt, both machines are efficient equipment. They function efficiently on their respective applications. But, 5-axis machines have better flexibility in function. They can do more than the basic functions of a 3-axis machine with better quality.

The 5-axis machine operation also saves time as it requires less manual intervention. Tool changes are lessened due to the integrated movements. You can finish a workpiece in a single operation without repositioning the tools or object.

5. Cost

Another factor that causes a significant gap between the two is the overall cost. From buying to programming to operation, the cost is a big difference.

A standard 3-axis CNC machine can cost around US$25,000 to US$50,000, depending on the type and brand. This is the average buying price of such machines, which may or may not include programming costs.

At least US$80,000 is required to purchase a 5-axis CNC machine. Larger machines and more popular brands can cost over US$500,000.

Besides the initial setup price, you will pay for programming and operations costs. CNC machines consume a lot of electricity. A 20hp CNC machine rated for 7kw/hr can land you a $1,400 monthly electric bill.

Most machines include a standard tool package. You will incur additional costs if you need more specific tools that are not included in the package. Finally, maintenance costs must also be taken into account. Ultimately, 5-axis CNC machines will cost you a more significant amount.

6. Handling

The operational requirement for a 3-axis CNC machine is less than the 5-axis CNC machines. This is based on the complexity of running the two.

Since the 5-axis is more complex, specialized training and expertise are needed to program and operate it. More moving parts also mean critical monitoring during operation. Since the 3-axis machine is less complex, it is easier to run and operate. Troubleshooting operational errors is also more critical and challenging for 5-axis machines.

Conclusion

There’s a huge gap between how a 3-axis CNC machine functions compared to a 5-axis. Among other factors, the two have their distinct offerings that suit different applications.

When choosing between the two, their application must be the primary factor dictating your option. If your fabrication needs to produce simple parts, a 3-axis machine is right for you. While it does not have the flexibility of a 5-axis, it is suited for such an application.

Only opt for a 5-axis machine when you’re going to produce more intricate pieces that a 3-axis can not handle. Understanding the scale of your production needs is also key getting the most suitable machine.