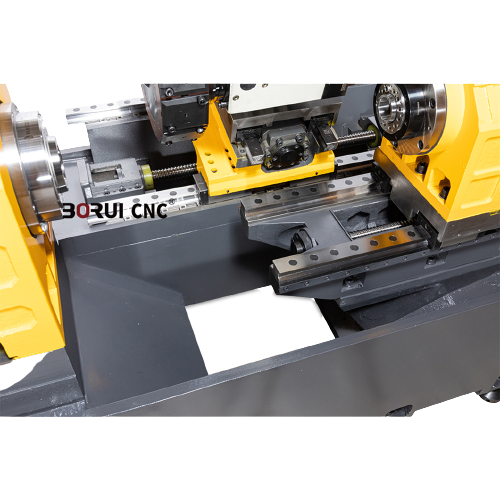

The tool arrangement of the CNC machine tool of the dual-spindle lathe, turning and milling compound machine tool adopts a three-dimensional tool arrangement structure. Compared with the turret tool holder, the tool change time is short and the failure rate is low. To meet the needs of machining parts, install multiple types of toolholders, which can clamp various tools from multiple directions and multiple positions, so as to reasonably process the characteristics of the parts.

Double-spindle lathe turning-milling compound machine tool is designed with advanced high-precision, high-rigidity electric spindle, and the main drive adopts stepless frequency conversion speed regulation, which can realize high and low speed milling of workpiece. The machine tool guide rail is designed with high rigidity, high precision, and the feed is stable without crawling, which can realize constant linear speed milling. The lathe has the characteristics of fast tool change, high positioning accuracy, and labor saving. It is suitable for multi-variety, small and medium-sized batch processing, with strong process adaptability, low rejection rate, and good product processing stability, which can reduce the requirements for the technical proficiency of operators. Cast iron base, iron filings and coolant box are collected for easy cleaning. The spindle adopts stepless speed regulation and has the function of constant linear speed machining to meet the requirements of different diameter machining surfaces.

Double-spindle lathe turning and milling compound machine tool CNC machine tool can be equipped with automatic feeder, automatic feeder, protective door and other additional facilities and form a flexible processing production line to complete the automatic processing of parts. Double-spindle lathe turning-milling machine tool is a small high-speed turning-milling machine tool with multiple functions. The main and auxiliary shafts are equipped with Y-axis milling function. It can be equipped with a variety of functional processing tools according to product requirements, from small batches of multiple varieties to large-scale production, and with intelligent cooperation, unmanned production will be realized in the future. Processing time, save labor, reduce processes, speed up shipments, and reduce warehouse pressure.

Features Of Double Spindle Turning And Milling Machine Tool:

- The electric spindle is designed with advanced high precision and high rigidity. The main drive adopts stepless frequency conversion speed regulation, which can realize high and low speed milling of workpieces.

- The machine tool guide rail is designed with high rigidity, high precision, stable feed without crawling, and can realize constant linear speed milling.

- Manual and semi-automatic operation modes are optional; a feeding device can be added to realize fully automatic production and save manpower.

- With linear and exponential acceleration and deceleration control and program pre-reading functions, it is suitable for high-speed and high-precision machining.

- The machine tool guide rail is designed with high rigidity, high precision, stable feed without crawling, and the surface of the machined parts can ensure a good finish.

- Working mode and performance: The vibrating disc track manipulator is connected to automatic loading and unloading, and the machine tool is automatically processed. Note: (automatic unit is removable)

- Operating system type: The specific system can be customized according to customer needs.

- One employee can operate 8-12 machine tools.